Honeywell Midas ®- M gas monitoring system

Product overview

Honeywell Midas ®- The M gas monitoring system is an easy-to-use and cost-effective device in Honeywell’s gas detection product portfolio, utilizing reliable sensor technology to easily, quickly, and error free detect over 35 key toxic, environmental, and flammable gases. This device is capable of monitoring detection points up to 30 meters (100 feet) away, while using patented technology to regulate flow to ensure error free gas detection.

Its standard power and communication functions include three onboard relays (Form C), 0mA to 21mA analog outputs, and Modbus ®/ TCP Ethernet digital output facilitates connection to ports of control and alarm systems for optimal connectivity and service interaction.

The Midas-M gas detector has flexible features and options, can be used out of the box, and is easy to configure to meet your needs. Each plug and play sensor box is pre calibrated to extend sensor life, facilitate quick and easy replacement, and prevent operator errors due to incorrect or depleted sensors. In addition, the device also has an extended sensor calibration cycle and patented diagnostic function, which can reduce the cost of ownership.

Application scenarios

Suitable for various scenarios, including semiconductor processing, light industry manufacturing, university laboratories, aerospace, wastewater treatment, etc.

Features and advantages

Clear visibility: Equipped with bright LED and intuitive interface, it can instantly display gas readings or alarm levels.

Calibration completed: Factory calibrated sensors reduce the need for frequent gas testing.

Easy to install: Compact in size, suitable for crowded and complex process environments with limited space, with plug and play functionality and simple installation.

PoE protocol: includes the innovative Power over Ethernet (PoE) protocol, which meets all power, control, and communication needs through a single Ethernet connection.

Integrated security: The interface includes a password protected menu to maintain system integrity.

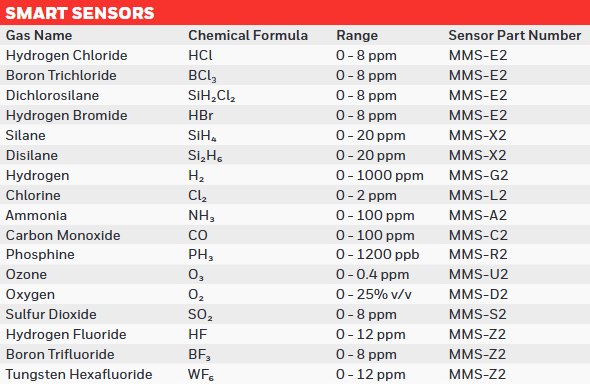

Technical specifications

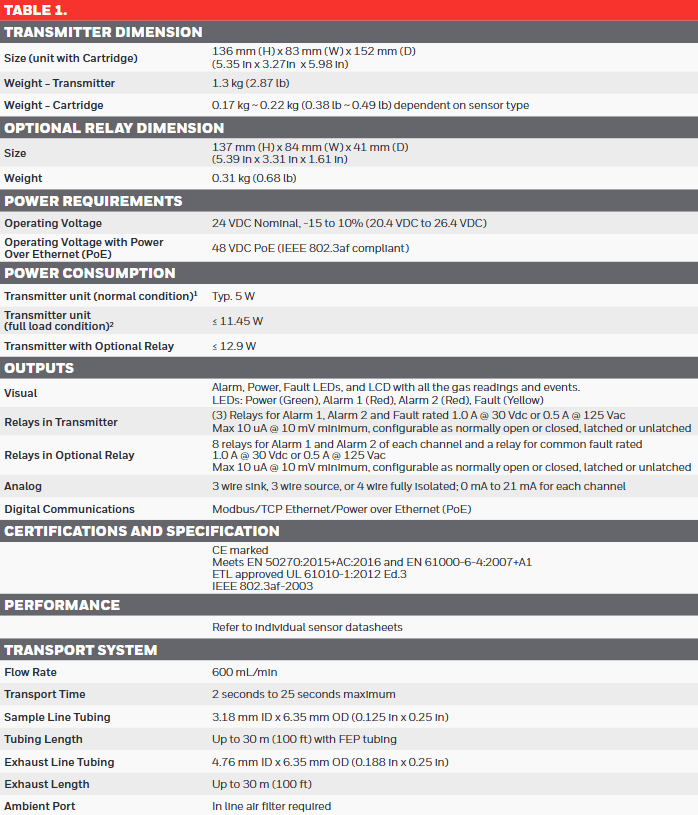

Transmitter size

Equipment size with sensor box: 136mm (height) x 83mm (width) x 152mm (depth) (5.35 inches x 3.27 inches x 5.98 inches)

Weight of transmitter: 1.3kg (2.87 pounds)

Sensor box weight: 0.17kg~0.22kg (0.38 pounds~0.49 pounds), depending on the sensor type

Optional relay size

Dimensions: 137mm (height) x 84mm (width) x 41mm (depth) (5.39 inches x 3.31 inches x 1.61 inches)

Weight: 0.31kg (0.68 pounds)

Power requirements

Working voltage: nominal 24VDC, -15% to+10% (20.4VDC to 26.4VDC)

Working voltage with Power over Ethernet (PoE): 48VDC PoE (compliant with IEEE 802.3af standard)

Power consumption

Transmitter unit (normal conditions): typical value 5W

Transmitter unit (full load condition): ≤ 11.45W

Transmitter with optional relay: ≤ 12.9W

Output

Visual output: alarm, power, fault LED and LCD, displaying all gas readings and events. LED includes power (green), alarm 1 (red), alarm 2 (red), and fault (yellow).

Relays in the transmitter: 3 relays, used for alarm 1, alarm 2, and fault respectively, with a rated value of 1.0A@30Vdc perhaps 0.5A@125Vac , the smallest 10uA@10mV , can be configured as normally open or normally closed, locked or unlocked.

Optional relays: 8 relays for each channel’s alarm 1 and alarm 2, as well as 1 common fault relay with a rated value of 1.0A@30Vdc perhaps 0.5A@125Vac , the smallest 10uA@10mV , can be configured as normally open or normally closed, locked or unlocked.

Analog output: 3-wire drain, 3-wire source, or 4-wire completely isolated; Each channel ranges from 0mA to 21mA.

Digital communication: Modbus/TCP Ethernet/Power over Ethernet (PoE)

Certification and specifications

Has CE mark and complies with EN 50270:2015+AC: 2016 and EN 61000-6-4:2007+A1 standards.

Obtained ETL certification and complies with UL 61010-1:2012 Ed.3 standard.

Compliant with IEEE 802.3af-2003 standard.

Performance

Refer to the data sheets of each sensor.

Transmission system

Flow rate: 600mL/min

Transmission time: maximum 2 seconds to 25 seconds

Sampling pipeline: 3.18mm inner diameter x 6.35mm outer diameter (0.125 inches x 0.25 inches)

Pipeline length: up to 30m (100 feet) using FEP pipe

Exhaust pipeline: 4.76mm inner diameter x 6.35mm outer diameter (0.188 inches x 0.25 inches)

Exhaust length: up to 30m (100 feet)

Environmental port: requires online air filter

operation temperature

0 ° C to 40 ° C (32 ° F to 104 ° F)

Wiring requirements

4-20mA: 2-wire, maximum 14AWG

Number: CAT5 cable or equivalent product: RJ45 connector

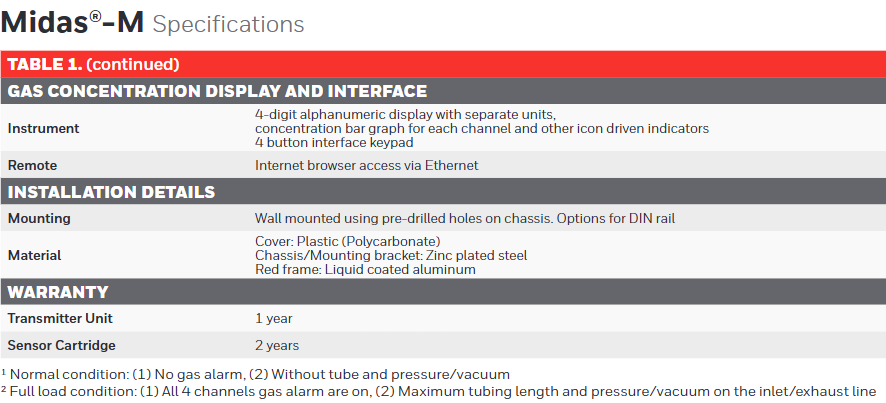

Gas concentration display and interface

Instrument: 4-digit alphanumeric display with separate units, concentration bar charts for each channel, and other icon driven indicators, with a 4-point interface keyboard.

Remote: accessed through an Internet browser over Ethernet.

Installation Details

Installation method: Use pre drilled holes on the chassis for wall mounting. Optional DIN rail installation.

Material: The lid is made of plastic (polycarbonate), the chassis/mounting bracket is made of galvanized steel, and the red frame is liquid coated aluminum.