Emerson DeltaV Ethernet I/O Card (EIOC)

Core positioning and core advantages

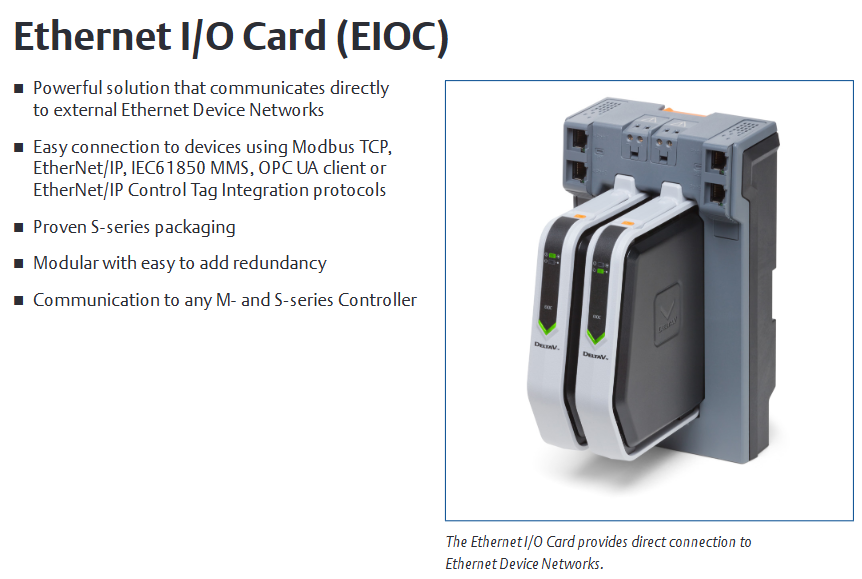

DeltaV Ethernet I/O Card (EIOC) is an embedded data server designed specifically for DeltaV systems to access external Ethernet device networks. It supports multiple industrial Ethernet protocols and can directly communicate with third-party Ethernet devices (such as PLCs, motor control centers, intelligent electronic devices, etc.) to achieve data acquisition and device control. Its core advantages can be summarized as seven key features:

Direct connection to Ethernet device network: No intermediate gateway is required, and external Ethernet devices can be directly connected through Modbus TCP, EtherNet/IP, IEC 61850 MMS, OPC UA client, and EtherNet/IP control tag integration protocol. It supports device monitoring and control, operates independently of DeltaV controller, and reduces system complexity.

High capacity and scalability: The license mode based on the number of device connections adapts to different needs, and the data access capability varies with the protocol: under the Modbus TCP/Ethernet/IP/IEC 61850 MMS protocol, up to 256 devices and 32000 signals can be accessed; Under the OPC UA client protocol, up to 64 servers and 30000 real-time signals can be accessed; Under the EtherNet/IP control tag integration protocol, up to 256 devices and 2000 tags (10 signals per tag) can be connected to meet the requirements of large-scale industrial scenarios.

Complete monitoring and control functions: The accessed data can be processed in the built-in control module of EIOC, supporting alarm generation, historical data collection, and operator interface display. The functions are consistent with traditional DeltaV controllers; Supports discrete control and limited PID control function blocks, without the need to allocate them to DeltaV controllers, and can directly control Ethernet devices such as motors, switchgear, and frequency converters.

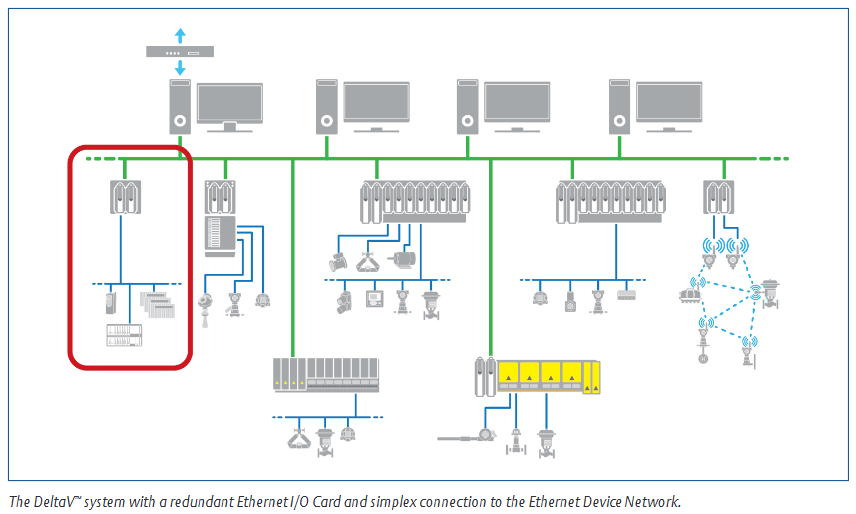

Powerful processing capability: A single EIOC can run up to 2000 control modules, and the system supports up to 60 EIOCs directly connected to the DeltaV control network, flexibly achieving network isolation and adapting to complex factory network architectures.

Flexible network configuration: Users can manually configure the IP address of Ethernet device networks to adapt to various factory network solutions; The simplex design requires EIOC to be on the same IP subnet as the device, while the redundant design requires EIOC primary and backup ports to be on different subnets (following best engineering practices); Support for Parallel Redundancy Protocol (PRP), seamless switching in case of redundant network failure, zero recovery time, and elimination of single point of failure.

Usability design: Native integration with DeltaV system, supporting 5 protocol choices (only 1 at a time, corresponding license required), EIOC and driver updates included in DeltaV system updates; The configuration is completely completed in DeltaV Explorer and Control Studio, consistent with the traditional I/O signal configuration process. The data can be accessed through the DeltaV Live/Operate interface and historical database, reducing the cost of operation and maintenance learning.

Modular redundancy design: The dual level carrier integrates redundant power input terminals and redundant Ethernet isolation ports. Adding one EIOC can achieve redundant configuration, and the system automatically identifies redundant pairs; Redundant Ethernet ports isolate communication between the DeltaV control network and Ethernet device networks, supporting manual triggering of switches in the DeltaV diagnostic browser to ensure high system availability.

Core components and functional details of the product

(1) Core hardware components

Component Name Function Description Key Features

EIOC card embedded data server, realizing communication with Ethernet devices and DeltaV control network. Single card supports 2000 control modules, input power 24V DC ± 10% (single redundancy 325mA max, dual redundancy 575mA max), heat consumption single redundancy 7W max, dual redundancy 13W max, with power/error/main/backup status/communication status LED indicator lights

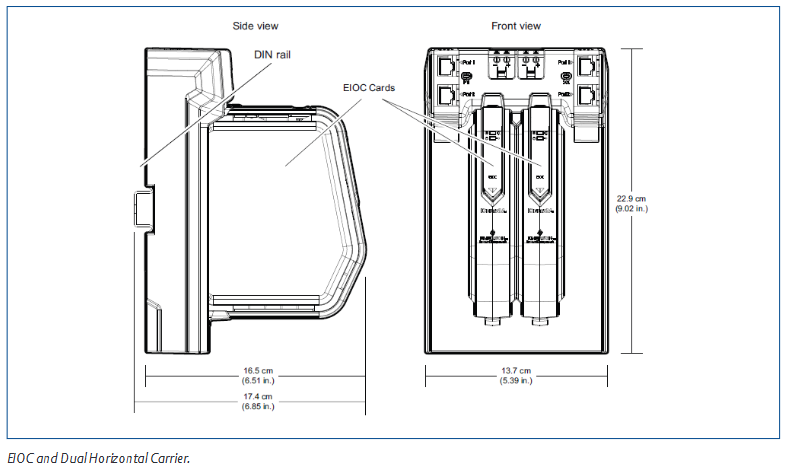

Double horizontal carrier DIN rail horizontal installation, supporting 1 (single redundancy) or 2 (double redundancy) EIOC cards and auxiliary components, providing redundant 24V DC power interface (1A max) and redundant Ethernet isolation port (copper cable 10/100BASE-TX, RJ45100m), including universal carrier protection cover

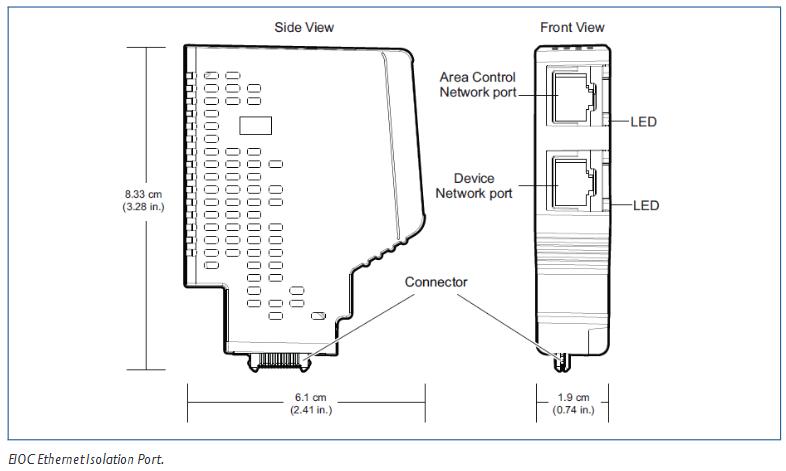

Ethernet isolation port enables physical isolation between DeltaV control network and Ethernet device network, supporting only copper twisted pair cables and connected through RJ45 interface to ensure network security and signal stability

The power plug provides 24V DC power input for the carrier and EIOC to adapt to redundant power configuration, ensuring reliable power supply

(2) Support protocols and key functions

1. Core Industrial Ethernet Protocol

Protocol type adaptation equipment key function data access capability

Modbus TCP PLC、 Motor Control Centers (MCC), analyzers, and other Modbus TCP devices (or Modbus serial devices connected through gateways) use EIOC as Modbus clients to read coil/discrete input/input register/hold register data and write coil/hold register data; Only supports MODICON (PLC) addressing, register addresses have range limitations (such as coil 1-9999), 256 devices, 32000 signals

EtherNet/IP PLC、 Intelligent field devices (IFDs), frequency converters, MCCs, etc. support implicit (Class 1) and explicit (Class 3) communication and are compatible with Class 1/3 I/O adapters; Support Class 3 PCCC and UCMM (with Logix tags) message classes; Redundant communication requires special configuration (refer to the DeltaV System Planning Guide) with 256 devices and 32000 signals

IEC 61850 MMS motor protection relays, motor starters MCC、 Intelligent electronic devices (IEDs) such as switchgear use EIOC as MMS clients to read and write real-time signals; Not supporting historical data reading and GOOSE application. 256 devices, 32000 signals

OPC UA client OPC UA server (third-party device or system) follows OPC UA 1.03 standard, supports Data Access (DA) protocol, and only processes real-time data; Supports 128/256 bit encryption, message signing, and digital certificates (self signing/CA authentication). 64 servers and 30000 signals can be configured for online/offline browsing through NodeSet files

EtherNet/IP control tag integration ControlLogix, CompactLogix and other tag based PLCs access data through tag names based on EtherNet/IP Class 3 messages (without register mapping); Support string signal reading and array reading/writing (up to 64 elements per array, up to 100 arrays per EIOC); Only supports controller scope labels, does not support program labels. 256 devices, 2000 labels (10 signals per label, for a total of 20000 signals)

2. Parallel Redundancy Protocol (PRP)

Function: Ethernet redundancy protocol, primary and backup network ports communicate simultaneously, devices receive the same data through dual paths, zero switching time in case of failure, eliminating redundant network single point failures, suitable for high availability demand scenarios (such as IEC 61850 MMS electrical monitoring).

Usage conditions: The device must have native support for PRP; Non PRP devices need to be connected through RedBox to avoid abnormal diagnostic status; PRP is independent of application protocols and can be used in conjunction with all EIOC supported protocols without the need for additional licenses.

(3) Control module and functional block limitations

Control module capability: A single EIOC can run up to 2000 control modules, supporting basic functional blocks such as alarm detection, AI/AO/DI/DO tag I/O, logical operations, mathematical calculations, timers/counters, etc. The module execution rate can be selected from 100ms-60s.

Function block restrictions:

Supports a limited number of specific functional blocks: 256 DC/EDC/DCC (motor control), 26 PID (analog control), 16 SEQ (stepper), 16 STD (state transition diagram).

Unsupported functions: Batch control, SFC (Sequential Function Diagram), PLM (Process Logic Manager), equipment module, complex control requires PK controller or VIM2 card.

Hardware specifications and compatibility

(1) General Environment and Hardware Specifications

1. General environmental specifications (all components)

Category parameter details

Working temperature -40~70 ° C (-40~158 ° F), long-term high-temperature operation will shorten the service life

Storage temperature -40~85 ° C (-40~185 ° F)

Relative humidity 5%~95% (no condensation)

Protection level IP20

Pollutant level ISA-S71.04-1985 G3 level (with conformal coating)

Anti impact 10g half sine wave (continuous for 11ms)

Vibration 2~13.2Hz (1mm peak to peak), 13.2~150Hz (0.7g)

2. Core hardware dimensions and electrical parameters

Component size/electrical parameters

EIOC card height 13.7cm (5.39 inches), depth 17.4cm (6.85 inches), width 2.9cm; input power supply 24V DC ± 10%, built-in non replaceable fuse

Dual level carrier compatible with horizontal T-shaped DIN rail, Ethernet isolation port spacing of 6.1cm (2.41 inches), protective cover compatible with redundant slots

Ethernet isolation port supports 10/100BASE-TX, RJ45 interface, transmission distance of 100m

(2) System compatibility and certification

Compatibility requirements:

Software version: Modbus TCP/Ethernet/IP/IEC 61850 MMS requires DeltaV v13.3.1 or higher; OPC UA client/EtherNet/IP control tag integration/PRP requires v14. LTS or above.

Controller adaptation: Supports communication with M-series and S-series controllers, and EIOC control module parameters can be called by the controller through external references; Excluding the limit on the number of controller nodes, the system has a maximum of 60 EIOCs.

Network node limitation: The total number of EIOC, remote I/O nodes, CHARM I/O cards (CIOC), and wireless I/O cards (WIOC) shall not exceed 300.

Core certification:

Security certification: CE(EMC EN 61326-1)、FM(3600/3611)、CSA(C22.2 No.213-M1987/1010-1)、ATEX(94/9/EC、EN60079-0/15)、IECEx(IEC60079-0/15)、 Classification certification (IACS E10, ABS, DNV-GL).

Security level: Achilles level 2 (v13.3.1, v14. FP1, except for PRP communication).

Dangerous area: FM/cFM Class I Division 2 (Groups A-D, T4); ATEX/IECEx Zone 2(Ex nA IIC T4 Gc)。

Ordering Information and Preconditions

(1) Core Product Order List (Some Key Models)

Product Category Description Model

EIOC component single redundant EIOC component (including 1 EIOC, dual horizontal carrier, protective cover, 2 Ethernet isolation ports, 2 power plugs) SE4100

Dual redundant EIOC components (including 2 EIOCs, dual horizontal carriers, 2 Ethernet isolation ports, 2 power plugs) SE4101

Protocol License Modbus TCP Interface License VE4103

EtherNet/IP Control Label Integration License VE4104

EtherNet/IP interface license VE4105

OPC UA Client License VE4106

IEC 61850 MMS interface license VE4107

Equipment License EIOC/PK Controller Physical Equipment License (nn is the number of devices) VE4109Sxxx

Spare parts EIOC card KL2001X1-BD1

Ethernet isolation port (copper cable) KL1604X1-BA1

Double level carrier KL4104X1-BA1

Universal carrier protective cover SE6106

(2) Pre requirements

Installation in hazardous areas must follow the “DeltaV S Series Class 1 Division 2 Installation Guide” (12P5402) and the “DeltaV S Series Zone 2 Installation Guide” (12P5404).

Suggest configuring an industrial network firewall to restrict device and protocol level communication through deep packet inspection, in order to enhance network security.

DeltaV Simulate v14 only supports virtual EIOC (vEIOC) and does not support physical EIOC.

The VE4109Sxxx license is system level and can be assigned to EIOC or PK controllers. The number of licenses can be stacked (no upgrade license, additional license extension devices are required).