Bender LINETRAXX ® CTAC series

Product Overview

Bender LINETRAXX ® The CTAC series is a high-sensitivity transformer designed specifically for AC current monitoring. Its core function is to convert AC current into an assessable electrical signal, compatible with Bender’s residual current monitoring system (RCM/RCMS series) and IT system insulation fault location system (EDS series). It is widely used for current status monitoring and fault diagnosis of industrial electrical equipment. The product is divided into standard and EDS specific types, providing multiple inner diameter specifications to adapt to different cable sizes, strictly following the IEC 60664-1 standard, with reliable protection performance and installation flexibility.

Core models and compatible devices

Model type, specific model, inner diameter, compatible equipment, product number

Standard CTAC20 20mm RCM420, RCMS460/490, EDS440/460/490 B98110005

Standard CTAC35 35mm RCM420, RCMS460/490, EDS440/460/490 B98110007

Standard CTAC60 60mm RCM420, RCMS460/490, EDS440/460/490 B98110017

Standard CTAC120 120mm RCM420, RCMS460/490, EDS440/460/490 B98110019

Standard CTAC210 210mm RCM420, RCMS460/490, EDS440/460/490 B98110020

EDS specific CTAC20/01 20mm EDS441, EDS461/491 B98110006

EDS specific CTAC35/01 35mm EDS441, EDS461/491 B98110008

Key technical parameters

Category Standard Type (CTAC20/35/60/120/210) EDS Specific Type (CTAC20/35/01)

Rated conversion ratio 600/1 8000/1

Rated continuous thermal current 125A 6A

Rated short-time thermal current (1s) 2.4kA 0.36kA

Rated dynamic current (40ms) 6.0kA 0.9kA

Frequency range 15Hz~100kHz 15Hz~100kHz

Rated insulation voltage 800V 800V

Overvoltage category III III

Rated impulse voltage/pollution level 8kV/3 8kV/3

Protection level (internal/terminal) IP40/IP20 IP40/IP20

Flame retardant grade UL94 V-0 UL94 V-0

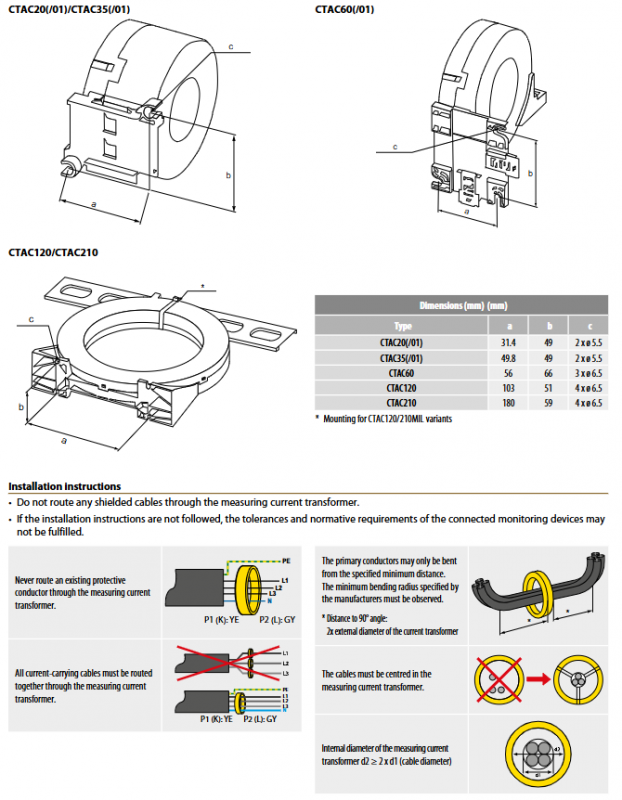

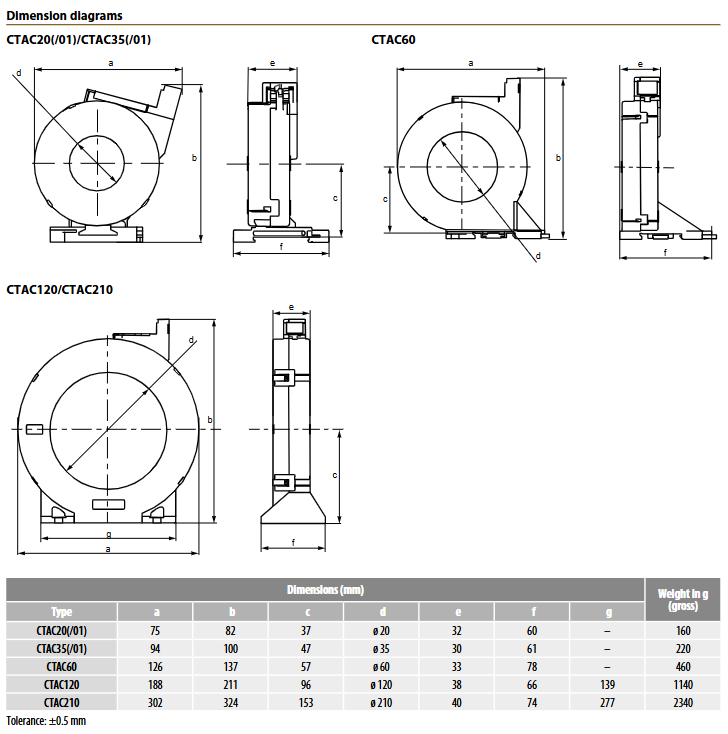

Size and weight

Model length a (mm) width b (mm) height c (mm) inner diameter d (mm) weight (g)

CTAC20(/01) 75 82 37 20 160

CTAC35(/01) 94 100 47 35 220

CTAC60 126 137 57 60 460

CTAC120 188 211 96 120 1140

CTAC210 302 324 153 210 2340

Tolerance ± 0.5mm ± 0.5mm ± 0.5mm ± 0.5mm-

Installation and wiring specifications

(1) Installation requirements

All current carrying cables must pass through the center of the transformer together, and it is strictly prohibited to pass the protective conductor through the core;

Do not pass shielded cables through transformers, otherwise it will affect measurement accuracy;

A conductor bending must maintain a minimum distance (90 ° angle distance=2 x outer diameter of the transformer) and be aligned with the center of the transformer;

Fixing method: Use M5 screws for CTAC20 (/01)/35 (/01)/60 and M6 screws for CTAC120/210, with tightening torques of 0.6Nm and 1Nm respectively.

(2) Wiring specifications

Wire requirements: rigid/flexible wire (0.2~2.5mm ², AWG24~12), with a stripping length of 7mm;

Cable length: Single stranded wire (≥ 0.75mm ²) up to 1m, twisted wire (≥ 0.75mm ²) up to 10m, shielded cable (≥ 0.5mm ²) up to 40m;

Recommended shielded cable model: J-Y (St) Y min. 2×0.8, RCM system requires one end to be connected to an L conductor (not grounded), EDS system requires one end to be connected to PE;

Terminal type: The standard type is screw terminal, while the MIL variant is push wire terminal (Phoenix Contact brand).

Accessories and Delivery

Supporting accessories: CTAC20 (/01) snap on installation part (B91080111), CTAC35 (/01) snap on installation part (B91080112);

Delivery includes: transformer body, corresponding PCB connector (MIL variant);

Customization options: B781100xxMIL variant models can be ordered as needed.