YASKAWA ∑ – V series AC servo drive

Overview

Type: YASKAWA ∑ – V Series AC Servo Drive User Manual (Design and Maintenance)

Applicable products: SERVOPACK (SGDV series)+servo motor (rotary type: SGMMV/SGMJV, etc.); Direct Drive Type: SGMCV/SGMCS

Core objective: To guide the entire process of product design, testing, adjustment, and maintenance, and meet the requirements of high-frequency, high-speed, and high-precision positioning

Core technical parameters

Parameter category, key specifications, typical values/ranges

Power supply specifications: single-phase 100V 100-115VAC,+10%/-15% 50/60Hz

Three phase 200V 200-230VAC,+10%/-15% 50/60Hz

Three phase 400V 380-480VAC,+10%/-15% 50/60Hz

Performance indicator speed control range 1:5000

Speed load regulation rate ± 0.01% (at rated speed)

Torque control repeatability ± 1%

Environmental requirements: Operating temperature range of 0-55 ° C

Relative humidity ≤ 90% RH (without condensation)

Altitude ≤ 1000 meters

Key operations and settings

(1) Panel and parameter operation

Digital operator functions: parameter configuration (Pn series), utility functions (Fn series), monitoring display (Un series)

Parameter classification: Setting parameters (such as Pn002 encoder type), tuning parameters (such as Pn103 moment of inertia ratio)

Core parameters: electronic gear ratio (Pn20E/Pn210), torque limit (Pn402/Pn403)

(2) Communication settings

Communication Protocol: MECHATROLINK-III

Key parameters: Station address (03h EFh), baud rate 100Mbps, transmission period 125 μ s-4ms

Wiring requirements: CN6A/CN6B connectors, maximum length of shielded cable 75m

(3) Security function

HWBB hard wired base block: dual input (/HWBB1//HWBB2), cuts off motor current within 20ms

EDM1 monitoring signal: normal status ON, fault status OFF, requires host monitoring to meet PLd level

Safety protection: emergency stop configuration, vertical axis anti fall braking, overtravel protection (P-OT/N-OT)

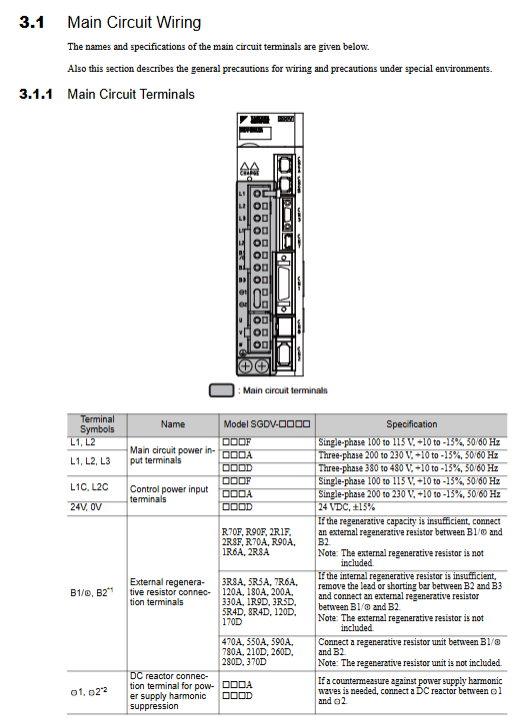

Wiring and installation specifications

(1) Wiring requirements

Main circuit cable: HIV series, cross-section ≥ 1.25mm ² (low power) to 22mm ² (high power)

Signal cable: The longest I/O cable is 3m, the longest encoder cable is 50m, and the shielding layer is grounded at one end

Distance requirement: The distance between power cables and signal cables should be ≥ 30cm, and wiring in the same conduit is prohibited

(2) Installation specifications

Environmental restrictions: No corrosive gases, no strong magnetic fields, keep away from electronic medical equipment (safety distance ≥ 1m)

Fixed requirement: 10.9 grade hexagonal socket screw, tightening torque 3.6-41.5N · m (depending on model)

Grounding requirements: 200V series grounding resistance ≤ 100 Ω, 400V series ≤ 10 Ω

Adjustment and Calibration

Applicable scenarios for tuning function code

Fn200 without tuning requires no manual adjustment and adapts to different load stiffness

Advanced self-tuning Fn201 automatically adjusts gain, filter, and friction compensation

Reference self-tuning note 202: Dynamic tuning based on host reference input

Anti resonance control injection 204 suppresses 100-1000Hz vibration

Vibration suppression Fn205 suppresses residual vibration of 1-100Hz during positioning

Maintenance and troubleshooting

(1) Regular maintenance

Daily inspection: clean appearance, no wear on cables, no abnormal vibration

Annual inspection: Insulation resistance (≥ 10M Ω), gap calibration (0.8-1.4mm)

Component replacement: Cooling fan (4-5 years), smoothing capacitor (7-8 years)

(2) Common faults

Fault type alarm code solution

Encoder battery fault A.830 Replace JZSP-BA01 battery, restart and clear

Overtravel alarm A.9A0 check P-OT/N-OT signal wiring, reset limit switch

Communication failure – checkpoint address, DIP switch settings, power restart

Compliance and scrapping

Compliance standards: North American UL 508C, CSA C22.2 No.100; EU EMC Directive 2014/30/EU

Environmental requirements: RoHS restricts 6 harmful substances, and scrap follows WEEE classification disposal

Prohibited modification: Do not disassemble the motor winding, magnetic track or modify the circuit, otherwise the warranty will be invalid