YASKAWA SGMCS series direct drive servo motor

Overview

Type: YASKAWA Direct Drive Servo System Product Manual

Core objective: To provide selection, technical parameters, system construction, and wiring guidance for motors and amplifiers, and to assist in the integration of high-precision equipment

Target audience: Equipment designers, electrical engineers, selection specialists

Product lineup and model description

1. Servo motor (SGMCS series)

Capacity type, outer diameter specification (mm), model series, rated torque (N · m), peak torque (N · m), rated speed (min ⁻¹)

Small Capacity 135 (Type B) SGMCS-02B/05B/07B 2/5/7 6/15/21 200-500

175 (Type C) SGMCS-04C/10C/14C 4/10/14 12/30/42 300-500

230 (D type) SGMCS-08D/17D/25D 8/17/25 24/51/75 250-500

290 (E-type) SGMCS-16E/35E 16/35 48/105 200-500

Medium capacity 280 (M-type) SGMCS-45M/80M/1AM 45/80/110 135/240/330 150-300

360 (N-type) SGMCS-80N/1EN/2ZN 80/150/200 240/450/600 150-250

Model interpretation (taking SGMCS-04C3C11 as an example):

04: Rated torque 4N · m; C: Outer diameter 175mm; 3:20 bit absolute encoder; 11: No brake+drive end C-face flange

Core configuration: 20 bit encoder (standard absolute type, optional incremental type), fully enclosed self cooling design, hollow structure (compatible with wiring/piping)

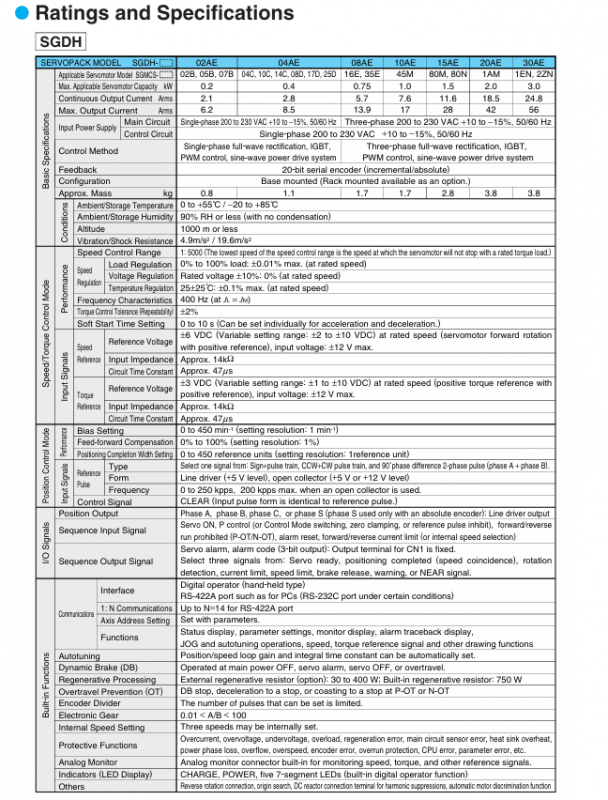

2. Servo amplifier (SGDS/SGDH series)

Series power supply specifications adapted to motor capacity control function core parameters

SGDS single-phase 100V/200V small capacity (2-35N · m) position/speed/torque control, electronic gear continuous output current 2.1-11.6Arms

SGDH single-phase/three-phase 200V full capacity (2-200N · m) with SGDS function+self-tuning, harmonic suppression continuous output current 2.1-24.8Vrms

Model interpretation (taking SGDS-02A01A as an example):

02: Suitable for 0.2kW motor; A: 200V power supply; 01: Standard interface (analog voltage/pulse)

Core technical parameters

1. Key parameters of the motor

Accuracy indicators: Absolute accuracy ± 15 seconds, repeatability accuracy ± 1.3 seconds, encoder resolution 1048576 P/R (20 bits)

Environmental parameters: working temperature 0-40 ℃, storage temperature -20-70 ℃, relative humidity 20% -80% (no condensation)

Insulation protection: Insulation resistance ≥ 10M Ω (500VDC), withstand voltage 1500VAC/1 minute, vibration level V15

Mechanical performance: allowable thrust load 50-16000N, allowable torque load 40-350N · m

2. Key parameters of amplifier

Control performance: speed control range 1:5000, load regulation rate ± 0.01% (rated speed), torque control repeatability ± 1%

Input/output: Analog reference ± 1-10V, maximum pulse frequency 1Mpps (line drive), I/O signal supports custom allocation

Protection function: multiple protections such as overcurrent, overvoltage, undervoltage, overload, encoder error, etc

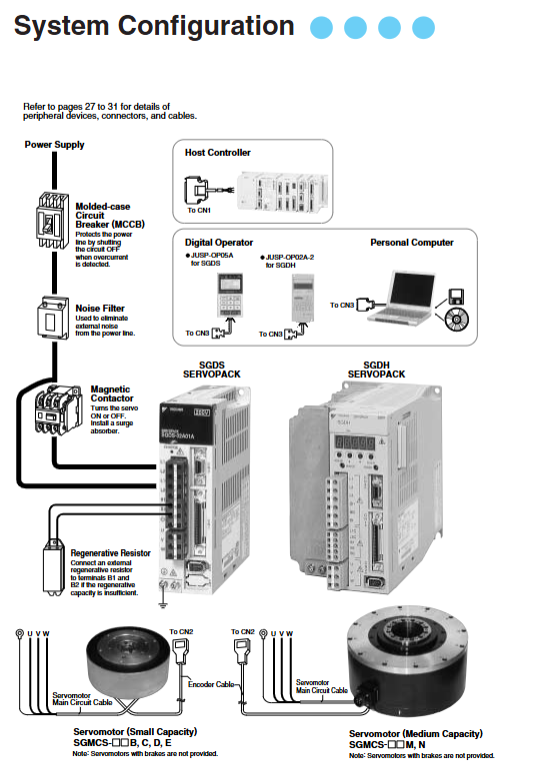

System configuration and wiring

1. Core component configuration

Power supply circuit: MCCB (molded case circuit breaker) → noise filter → electromagnetic contactor → amplifier

Signal circuit: host controller → amplifier CN1 (I/O) → motor CN2 (encoder)

Peripheral accessories: Regenerative resistor (when regenerative energy is insufficient), DC reactor (to suppress harmonics), surge absorber

2. Key wiring requirements

Main circuit: The U/V/W phase line of the motor corresponds to the amplifier output terminal, and the FG terminal must be grounded (grounding resistance ≤ 100 Ω)

Encoder: Shielded twisted pair cable, maximum distance of 50m, single ended grounding of shielding layer

Control circuit: Shielded twisted pair cables are used for I/O signals, with a distance of ≥ 30cm from the main circuit to avoid interference

3. Typical wiring diagram

Single phase 200V (SGDS): L1/L2 connected to single-phase power supply, B1/B2 connected to regenerative resistor, CN2 connected to encoder, CN1 connected to control signal

Three phase 200V (SGDH): L1/L2/L3 connected to three-phase power supply, 1/2 terminal connected to DC reactor, other interfaces consistent with single-phase

Selection and peripheral devices

1. Selection process

Determine load torque/speed → Select motor model (by outer diameter/torque)

Select amplifier (SGDS/SGDH) based on motor capacity/power supply type

According to system requirements → configure peripheral devices (filters, reactors, cables)

2. Selection of commonly used peripheral devices

Example of Equipment Type and Model Applicable Scenarios

Noise filter FN2070-6/07 suppresses power side noise and is suitable for 200W motors

DC reactor X5054 suppresses harmonics and is compatible with SGDS series

Digital Operator JUSP-OP05A Amplifier Parameter Configuration/Monitoring

Encoder cable JZSP-CMP60-05 motor amplifier encoder connection (5m)

Main circuit cable JZSP-CMM60-03 motor amplifier power connection (3m)

Advantages and limitations of application

Core advantages: gearless design (no backlash/wear), high-precision positioning, hollow structure saves space, lubrication free maintenance

Application restrictions: Operating temperature ≤ 40 ℃, altitude ≤ 1000m (over altitude requires derating), requires coordination with designated peripheral devices to ensure stability