TOSHIBA TOSBERT VF-AS3 series

Product basic information

Product Name: TOSBERT VF-AS3 Series Industrial Inverter

Core positioning: Designed specifically for industrial scenarios, used to control the speed of 3-phase induction motors, built-in permanent magnet synchronous motors (IPMSM), and surface permanent magnet synchronous motors (SPMSM), and does not support single-phase motors

Scope limitation: Not applicable to high-risk or quality control specific scenarios such as power plants, railways, nuclear power, aviation, life support, etc., only suitable for general industrial use

Core identification rules: The model consists of the series name, voltage level, capacity code, and function code (such as VFAS3-6750PC, where 6 represents 500V-690V and 750 represents the corresponding capacity)

Core specifications and performance parameters

(1) Voltage and power range

Voltage level, power range (HD rated), power range (ND rated), applicable motor capacity labeling

500V class 1.5kW-55kW 2.2kW-75kW in kW

600V (575V) class 2HP-75HP 3HP-100HP in HP units

690V class 2.2kW-75kW 3kW-90kW in kW

(2) Key performance indicators

Control method: sine wave PWM control

Output frequency: set range 0.01-590Hz, default 0.01-60Hz, frequency accuracy ± 0.01% ± 0.022Hz (digital input)

Carrier frequency: A1Y frame 1.0-6.0kHz (default 2.5kHz), A2Y frame 1.0-4.9kHz (default 2.5kHz)

Overload capacity: HD rated 150% -60s, ND rated 120% -60s

Frequency resolution: Input 0.1Hz on the operation panel, communication command 0.01Hz

Core protection functions: overcurrent, overvoltage, undervoltage, overload, short circuit, ground fault, overheating, etc

(3) Environmental and physical parameters

Working environment: Temperature -15 ° C~+60 ° C (capacity reduction required for temperatures above 50 ° C), relative humidity 5% -95% (no condensation), working altitude ≤ 2000m (capacity reduction of 1% for every 100m exceeding 1000m)

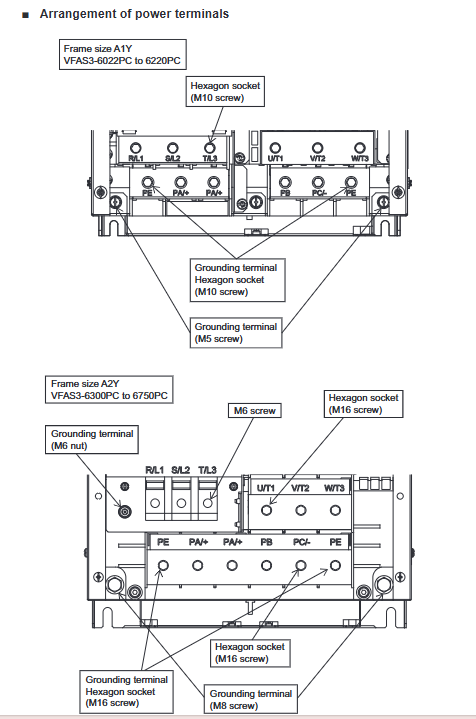

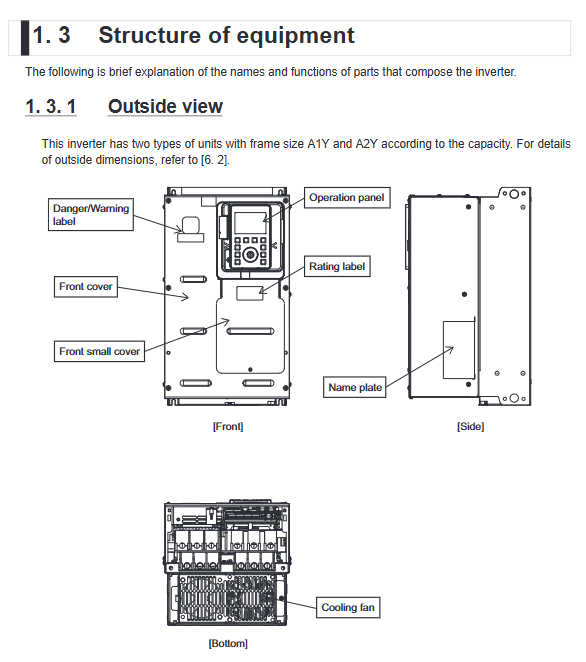

Physical specifications: There are two types of machine bases, A1Y (VFAS3-6022PC~6220PC) and A2Y (VFAS3-6300PC~6750PC), with a weight of 21.6kg~57kg

Cooling method: forced air cooling, cooling fan design life of 8 years

Protection level: IP00 (IEC60529), shell color RAL7016

Core functions and configurations

(1) Control and operation functions

Core control mode: supports multiple V/f characteristics such as constant V/f, variable torque, automatic torque boosting, vector control, etc

Operation functions: forward and reverse operation, jog operation, preset speed operation (up to 31 speeds), PID control, torque control, automatic acceleration and deceleration, etc

Display and Monitoring: Equipped with LCD/LED display screens, it can monitor output frequency, current, voltage, fault records, etc., and support fault trip record retention

Parameter settings: Support user default parameter saving, automatic search for parameters different from default values, multi regional parameter adaptation (Japan/North America/Asia/Europe/China)

(2) Interface and Communication Capability

Digital interface: 14 programmable digital inputs (6 optional), 3 programmable digital outputs (2 optional)

Analog interface: 5 frequency command inputs (2 optional), 2 programmable analog outputs

Communication interface: Built in Ethernet (dual port with switch, supporting EtherNet/IP, Modbus TCP, Webserver), 2-channel RS485 (supporting Modbus RTU); Optional protocols include PROFINET, DeviceNet, PROFIBUS DP, etc

Safe Interface: Supports Safe Torque Off (STO) function and complies with IEC61800-5-2 standard

Installation and wiring specifications

(1) Installation requirements

Installation foundation: It must be installed on a metal plate, and the rear panel should not be installed on flammable materials due to high temperature

Installation space: For single unit installation, a space of 10cm up and down, and 5cm left and right should be reserved; Multiple units installed side by side need to reserve a gap of ≥ 11mm, and capacity reduction is required in environments above 50 ° C or when installed side by side

Handling specifications: Models weighing over 20kg require 2 people to handle, VFAS3-6300PC~6750PC require a crane to handle, and it is forbidden to grip the front cover for handling

Peripheral equipment: Short circuit protection devices (such as MCCB, ELCB) and emergency stop devices must be installed, and thermal relays are required (when multiple motors are shared, each motor is separately configured)

(2) Wiring specifications

Core principle: Power must be disconnected before wiring, wait for at least 15 minutes, confirm that the charging light is off and the DC main circuit voltage is ≤ 45V before operation

Wiring requirements:

Power wiring: Connect a 3-phase power supply to the [R/L1], [S/L2], and [T/L3] terminals, with voltage fluctuations within ± 10% (± 10% during continuous operation at full load)

Motor wiring: Connect to [U/T1], [V/T2], [W/T3] terminals, and it is strictly prohibited to connect the power supply to the output terminal

Grounding requirements: The grounding wire should be firmly connected, with specifications not lower than the input/output wire, and should be grounded separately and not shared with the chassis screws

Braking resistor: can only be connected to [PA/+] and [PB] terminals, and it is strictly prohibited to connect between [PA/+] and [PC/-]

Warranty and Usage Restrictions

(1) Warranty terms

Warranty period: 12 months after purchase or 18 months after the production date on the product nameplate, whichever expires first

Warranty scope: Only covers malfunctions caused by manufacturing defects in the product itself, excluding problems caused by installation, debugging, or external equipment

Warranty Disclaimer: Misuse, modification, accidental fall, natural disasters, improper environment, failure to maintain according to the manual, and other situations are not covered by the warranty

(2) Usage restrictions and precautions

Operating restrictions: Cannot be used for environmental conditions beyond the manual specifications (such as high temperature, high humidity, and high dust scenes)

Maintenance requirements: Regularly check the cooling fan and replace vulnerable parts according to the manual

Troubleshooting: In case of smoke, odor, or abnormal noise, immediately turn off the power and contact a Toshiba dealer for repair. Do not disassemble or modify on your own