WOODWARD MicroNet TMR ® OpView

Basic information of the document

Document type: OpView Operator Interface Installation and Operation Manual

Manual Number: 85580V4 (Revision J)

Applicable scenarios: Suitable for Woodward MicroNet TMR ® 5009 digital control system, used for remote monitoring and control of steam turbines

Compatible models: covering 8 models of the 8236 series, with core differences in Com B port type (25 pin/9 pin) and hazardous area applicability

Model Number Screen Type Com B Port Hazardous Area Level

8236-354 Color 25 Needles-

8236-513 Color 25 Pin Class I, Division 2

8236-616 Color 25 Needles-

8236-617 Color 25 Pin Class I, Division 2

8236-700 Color 9-Needle-

8236-701 Color 9-Pin Class I, Division 2

8236-1001 Color 9-Needle-

Core safety requirements

(1) Warning definition and protection principles

Danger (DANGER): Failure to avoid causing death or serious injury

Warning: Failure to avoid may result in death or serious injury

CAUTION: Failure to avoid may result in minor or moderate injury

Notice: May only cause property damage

Important: Operation tips or maintenance recommendations

(2) Key safety measures

Anti static protection: Release human static electricity before contacting the equipment, avoid non anti-static materials from approaching the circuit board, and do not touch PCB components

Personal protection: PPE such as goggles, hearing protection equipment, helmets, gloves, and safety boots should be worn during operation

Explosion proof requirements: After installing the F/T relay module, the equipment is only suitable for ordinary or non hazardous locations; The use of Class I, Division 2 areas must comply with specific wiring specifications

High voltage protection: When the DTM terminal block has a high voltage of 125Vdc, it is necessary to avoid contact with the cable

Live operation restrictions: It is prohibited to plug in or unplug power supplies, modules, or equipment while live in hazardous areas

(3) Compliance requirements

Some models (8236-513, 8236-617, etc.) are suitable for Class I, Division 2, Groups A, B, C, D or non hazardous locations

When the ambient temperature exceeds 50 ℃, the rated temperature for on-site wiring should be at least 75 ℃

The maximum external voltage limit for discrete input and relay output circuits is 18-32Vdc (compliant with CE certification low voltage directive)

Product Description

Equipment type: Industrial grade touch screen workstation, with both alarm annunitor and operator control panel functions

Core functions: Remote viewing of operating parameters, adjustment of control settings, issuance of operating mode commands (such as start and stop)

Hardware features: Panel installation design, NEMA 4 protection level, weight 6.9kg (15.2lb)

Software features: Automatic matching of 5009 control system configuration, no need for on-site programming, supports graphical interface display of valve, turbine and other equipment status

Data storage: Record up to 500 alarm and trip information with a 1-second resolution timestamp

Extension function: Supports connecting to serial printers and outputting hard copies of alarm/trip logs

Installation process

(1) Installation requirements

Installation method: Panel installation, fixed with 12 installation bolts or 6 installation clips (depending on the model)

Space requirement: Reserve at least 2 inches (50.8mm) of space around the device to ensure heat dissipation

Environmental requirements: Installed in a closed cabinet or panel to prevent pollutants in the air from coming into contact with the rear shell of the equipment

Temperature range: Operating temperature 0-50 ℃ (32-122 ° F), please refer to the PowerStation manual for more environmental restrictions

(2) Communication configuration

Communication port: OpView is connected to the J3 port of the 5009 control system SIO module through the Com B port

Communication protocol: Supports RS-232, RS-422, RS-485 standards, protocol selection depends on device distance

Maximum distance port configuration for communication protocol

RS-232 15m (50ft) 25 pin/9-pin Com B port, wire according to corresponding pins

RS-422 1200m (4000ft) 25 pin port requires short circuiting of specific pins, 9-pin port is configured through DIP switch

RS-485 1200m (4000ft) 25 pin port requires short circuiting of specific pins, 9-pin port configured through DIP switch

Default communication parameters: baud rate 9600, no checksum, data bit 8, stop bit 1, consistent with the 5009 control system port settings

(3) Printer and Initial Settings

Printer settings: Connect the parallel printer to the OpView parallel port, use standard IBM parallel cables, configure protocols and communication parameters to match

Initial startup: After the device is powered on, perform a diagnostic test (which takes several minutes), and display the main menu after the diagnosis is successful; When communication is lost, wait for 20 minutes before displaying the application screen

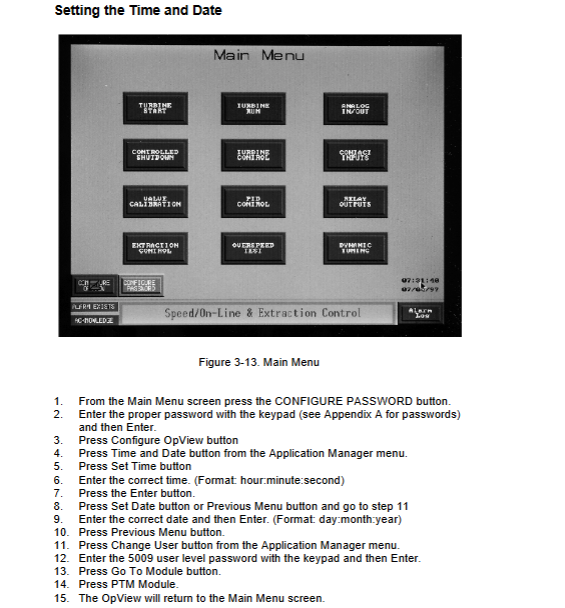

Time and date calibration: Enter the password through the main menu “CONFIGURE PASSWORD” and enter the application manager settings. The formats are “hour: minute: second” and “day: month: year”

Operation steps

(1) General operating rules

Operation method: Touch screen operation, button selection will change brightness or color to confirm response

Unit display: Consistent with the units configured in the programming mode of the 5009 control system (such as displaying KW or MW as load)

Communication loss handling: The screen displays “LOST Communication”, which allows browsing but cannot issue commands. The 5009 control system will generate an alarm, and the alarm needs to be reset to receive the set value after communication is restored

Local/Remote Switching: After configuring 5009, the main menu and dynamic/trend menu display switching buttons, and all screens (except trend screens) display status indicators

(2) Special function operation

Turbine Start: Select the start mode (Idle/Rated, Auto Start Sequence, etc.) through the “Turbine Start” screen, click “START” to issue the start command, and monitor the speed increase status

Turbine operation: Adjust the speed, extraction, and other settings on the “Turbine Run” screen, enable/disable frequency control, synchronizers, and other functions

Controlled Shutdown: Start the shutdown sequence through the “Controlled Shutdown” screen, and click “ABORT” to abort the shutdown

Valve Calibration: Enter the calibration password (1111), meet the permission conditions such as shutdown state and speed<1000RPM, adjust the valve opening through the “Valve Calibration” screen, and click “SAVE CALIBRATION” to save

PID adjustment: Enter the “PID Control” screen to view the output and set values of each PID, and enter the dynamic adjustment password to modify the proportional, integral, and derivative parameters

Overspeed Test: Perform electrical overspeed (TEST 5009 TRIP) or external overspeed (TEST ExternalRNAL TRIP) test on the “Overspeed Test” screen. If the set value is not adjusted within 60 seconds during the test, it will automatically terminate

Alarm Log: View active alarms (red with asterisks) through the “Alarm Log” screen, click “ALM ACK” to confirm, “RESET” to reset, “CLEAR” to clear, and support printer output logs

(3) Permission management

The operation permissions are divided into three levels, and access is required by entering the corresponding password through the pop-up keyboard

Permission level, password, core operation permissions

SUPVAR level 1113 access application manager, configure OpView

Calibration level 1111 dynamically adjusts PID parameters and valve calibration

5009 level 5009 basic monitoring, setting value adjustment, mode switching

It is recommended to restore permissions to level 5009 during normal operation to prevent unauthorized operations

Password information and product support

(1) Password details

SUPVAR Level Password:1113, Used to access the application manager and configure OpView system parameters

Tuner/Valve Calibration Level Password:1111, Used for dynamically adjusting controller parameters and valve calibration operations

5009 Level Password:5009, Used for daily basic operations, such as parameter viewing and issuing regular commands