WOODWARD 5009XT Fault-Tolerant Control

Description

The 5009XT is a standard-off-the-shelf steam turbine control for use on industrial steam turbines in reliability- critical applications. This controller utilizes Woodward’s field-proven MicroNet TMR® hardware platform combined with Woodward’s state-of-the-art XT steam control core and algorithms. The 5009XT is designed for use both in OEM turbine packages and for upgrade of existing turbines

The 5009XT’s triple-redundant, fault-tolerant design allows it to continue operating the turbine safety under any single point of failure. Modular design and hot-swapping capability allow maximum uptime and minimize maintenance shutdowns required for the control.

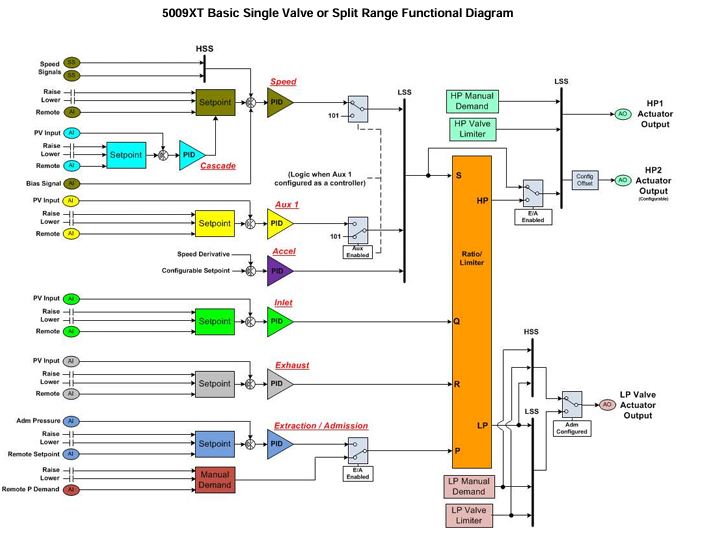

The 5009XT control’s unique PID structure makes it ideal for applications requiring accurate control of parameters such as turbine speed, load, extraction header pressure, inlet header pressure, and exhaust header pressure or tie-line power.

The control’s PID-to-PID logic allows stable control during normal turbine operation and bumpless control mode transfers during plant upsets, minimizing process over or undershoot conditions. The 5009XT controller senses turbine speed via passive or active speed probes and controls the steam turbine through actuators connected to the turbine inlet steam valves.

This field programmable controller allows users to easily make system configuration changes without the need of an OEM expert. The system can be controlled, configured, calibrated and tuned using the optional 17” touchscreen display or any workstation running Woodward’s RemoteView software. RemoteView can also function as an HMI for the system, allowing operators to monitor the system, start/stop the turbine, enable/disable all control modes, and view/reset system alarms. Multiple password security levels are available to provide different plant personnel with access to the different levels of the 5009XT’s configurations/ adjustments depending on site requirements. The RemoteView display can be networked to all three CPUs for maximum redundancy. See Specification 03424 for more information on RemoteView.

The 5009XT can be purchased as a kit or Woodward can package the system in a free-standing cabinet with an integral RemoteView HMI/engineering workstation. The 5009XT can be configured to operate as a stand-alone unit or in conjunction with a plant’s Distributed Control System, depending upon the site’s requirement.

Woodward or our partners can integrate the 5009XT software with our Vertex compressor-control core on a MicroNet TMR to create a fault-tolerant ITCC steam and compressor control.

Applications

The 5009XT is designed to control industrial steam turbines of all sizes and types in system-critical applications requiring maximum reliability and availability. This steam turbine controller includes specifically designed algorithms and logic to start, stop, control, and protect industrial steam turbines or turbo-expanders that drive compressors, generators, or pumps.

Designed for today’s plant standardization practices, the 5009XT control system’s versatile programing can be configured to control single valve, single extraction, single admission, or single extraction/ admission steam turbines. The 5009XT control’s unique PID structure makes it ideal for petrochemical or power generation applications requiring tight control of parameters like compressor speed, generator frequency, turbine load, turbine inlet or exhaust header pressures, or tie-line power.

The control’s TMR (triple modular redundant) architecture, TMR CPU and I/O modules, on-line configuration, and on line repair capability make it ideal for use in safety or reliability critical applications. This control’s fault tolerant design allows it to accept redundant inputs sensors, drive redundant actuators, and interface with redundant RemoteView operator stations, extending redundancy throughout the entire turbine package.

For applications requiring multiple human-machine-interfaces (HMIs), users can purchase additional licenses of Woodward’s RemoteView™ software for installation on any Windows PC installed on the network. Woodward also offers full HMI packages based on iFIX or Citect graphics packages.

For applications requiring IEC61508 SIL-3 certification, a MicroNet Safety Module (MSM) may be added to the base 5009XT system. The MSM functions as the system’s SIL-3 logic solver, and its fast (12 millisecond) response time and integrated overspeed and acceleration detection/protection functionality make it ideal for applications on critical turbines. For more information on the MicroNet Safety Module, refer to Woodward product spec 03375.

Triplex Architecture Advantages

• 2-out-of-3 voting provides accurate signal selection by excluding bad signals.

• 2-out-of-3 voting increases system fault coverage close to 100%, which provides an availability of 99.998% or higher.

• CPU or I/O module failures are accurately detected, and related calculations safely removed, while the turbine continues to operate.

• Output relay failures can be detected and repaired with the turbine on-line.

5009XT Key Functionality

• Speed/frequency control

• Turbine or generator load control/limiting

• Extraction and/or admission header pressure control

• Turbine inlet header pressure control/limiting

• Turbine exhaust header pressure control/limiting

• Plant import/export power control/limiting

• Isochronous load sharing between units

• Any process directly related to unit load

• Proportional or integrating Servo Position Control with LVDT/RVDT excitation (with optional modules)

Operational Features

• Fault-tolerant I/O handling and processing

• Latent fault detection on relay outputs

• Time-stamped alarms, with 10ms resolution on trips

• Overspeed anticipation and shutdown protection

• Peak speed indication for overspeed trip

• Configurable over or under pressure shutdown logic

• Three Critical speed avoidance bands

• Patented OPTI Tune and OPTI Ratio algorithms provide adaptive speed and extraction dynamics

• Discrete input time-stamp with 1 ms resolution, Analog input time stamp with 5 ms resolution

• Extensive fault detection and annunciation, including first-out indication

• Auto start sequence (hot & cold starts)

• Three sensors can be configured for each critical parameter

• Dual speed/load dynamics

• Zero speed detection with proximity probe down to 0.5 Hz

• Automatic hand valve operation (using first stage pressure)

• Remote analog setpoints for all PIDs

Connectivity / Security Features

• Independent Modbus® * communication links

• RemoteView software for any Windows 17” (43 cm) touchscreen engineering workstation for configuration, service, and turbine operation.

• Multi-lingual interface (English, Chinese, Portuguese, Japanese, Spanish and Russian).

• User level management with secure password authentication

• Achilles Cybersecurity certification

Options

• 2 Channel Actuator Modules (use for proportional or integrating actuators)

• Distributed SPC (servo position control) modules on CANOpen

• RemoteView touchscreen HMI/Workstation

• Additional RemoteView licenses for multiple workstations

• ITCC integrated compressor control (Woodward quote)

• Control cabinet (Woodward quote)

Control Specifications

Inputs

Power: Redundant power supplies with the following input options: 18–32 Vdc, 100–150 Vdc, 88–132 Vac (47–63 Hz), 180–264 Vac (47–63 Hz), 200–300 Vdc Speed: 4 MPUs (1–30 Vrms) or proximity probes (24 Vdc and 12 Vdc power provided), 0.5 to 25 kHz

Discrete Inputs: 24 contact inputs 24 V (CE or UL) or 125 Vdc (UL only) (1 dedicated, 23 programmable)

Analog Inputs: 8 programmable 4–20 mA inputs (32 inputs with compressor control option)

Outputs

Valve/Actuator Drivers: 2 single-coil (proportional) or 2 dual-coil actuator outputs (4–20 mA)

Optional—2 proportional 20-160 mA or integrating ±200 mA max actuator outputs with

2 LVDT or RVDT or 1–5 V or 4–20 mA position feedback inputs

Discrete Outputs: 12 relay outputs with latent fault detection (1 dedicated, 11 programmable)

Analog Outputs: 4 programmable 4–20 mA outputs (12 outputs with compressor control option)

Communication

Ethernet: 6 10/100BaseT Ports (Modbus TCP or UDP & Service Tool communication)

Serial: 3 Modbus (ASCII or RTU) communication ports (RS-232, RS-422, RS-485 compatible)

Operating Conditions

Temperature: 0° – 55˚ C (32° – 131˚ F) ambient air temperature

Emissions: EN61000-6-4

Immunity: EN61000-6-2

Regulatory Compliance

(Listings are limited only to those units bearing the appropriate Marking or Agency Identification)

European Compliance EMC Directive: 2014/30/EU

for CE Marking:Low Voltage Directive: 2014/35/EU

North American CSA Certified for Ordinary Locations in the United States and Canada per

Compliance:CSA Certificate 2291171

5009XT Chassis

Bulkhead or Adaptable to 19” (483 mm) rack-mount back panel with 18 slots

Approximate dimensions:

Control Chassis: 19” wide x 14” high x 12” deep (483 mm wide x 356 mm high x 305 mm deep)

Power Chassis: 7” wide x 14” high x 12” deep (178 mm wide x 356 mm high x 305 mm deep)

Approximate Weight: 56 lb (25 kg) fully loaded