WOODWARD VariStroke-I (VS-I) electro-hydraulic actuator

Basic Information

Type: Installation, Operation, and Maintenance Manual for VS-I Electro Hydraulic actuator

Applicable scenarios: Designed specifically for precise control of steam turbine valves, suitable for fields such as electricity and industrial power

Core value: Provide full lifecycle guidance from product recognition, installation, configuration to maintenance, ensuring safe and stable operation of equipment

Core safety requirements

(1) Warning definition and protection principles

Danger (DANGER): Failure to avoid causing death or serious injury

Warning: Failure to avoid may result in death or serious injury

CAUTION: Failure to avoid may result in minor or moderate injury

Notice: May only cause property damage

Important: Operation tips or maintenance recommendations

(2) Key safety measures

Anti static protection: Release human static electricity before contacting the equipment, avoid non anti-static materials from approaching the circuit board, and do not touch PCB components

Explosion proof compliance: Some models are suitable for Class I, Div.1/2, ATEX Zone 1/2 and other hazardous areas, and wiring must comply with corresponding specifications

Personal protection: PPE such as goggles, hearing protection equipment, helmets, gloves, and safety boots should be worn during operation

High pressure/overspeed protection: The hydraulic system needs to be equipped with independent overpressure protection, and the steam turbine needs to be equipped with an independent overspeed shutdown device

Live operation restrictions: It is prohibited to plug or unplug power supplies, modules, or cables with power in hazardous areas

(3) Compliance requirements

Key requirements for the scope of application of compliance standards

ATEX Directive 2014/34/EU Zone 1/2 Zone 1:II 2 G Ex db IIB T4 Gb; Zone 2:II 3 G Ex nA IIC T4 Gc

CSA Class I, Div.1/2 is applicable to Canada and the United States, Groups A-D T4

IECEx Zone 1/2 international explosion-proof certification, Ex db IIB T4 Gb(Zone 1)

CE (EMC) complies with Directive 2014/30/EU in the EU region

Product specifications and structure

(1) Core specification parameters

Category key parameter details

Physical parameters aperture 4/5/6/8/10 inches (100/127/150/200/250mm)

Rod diameter 1.75/2.5/3.5/4.5 inches (corresponding to aperture)

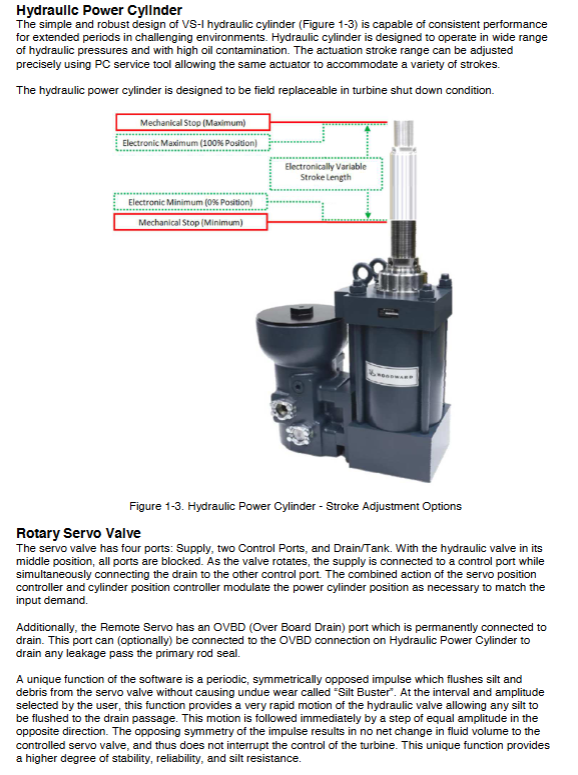

The electronic travel is adjustable, and the maximum mechanical travel depends on the model

Electrical parameters: Supply voltage 18-32Vdc (nominal 24Vdc), steady-state current 2.3A, transient 10A (100ms)

Input signal 2-channel redundant 4-20mA demand signal (input impedance 200 Ω)

Output signal 1 channel 4-20mA position feedback (load ≤ 500 Ω), 4 channels discrete output (0.5A/32Vdc)

Position sensor integrated with MLDT (magnetostrictive linear displacement sensor), accuracy ± 0.04%

Hydraulic parameters: minimum working pressure of 5.5 bar (80 psi), maximum working pressure of 34.5 bar (500 psi)

Oil type: petroleum based hydraulic oil or fire-resistant hydraulic oil (such as Fyrquel EHC)

The oil temperature is continuously between 15-70 ℃ (59-158 ° F)

Cleanliness requirements ISO 4406 code 20/18/16 or higher

Environmental parameters Operating temperature ambient: -40 to 85 ℃ (-40 to 185 ° F)

Protection level IP66 (IEC 60529)

Vibration/impact complies with MIL-STD 810F/G standard

Performance parameter positioning accuracy ± 1% full stroke

Repetitive accuracy ± 0.5% full stroke

Temperature drift MLDT: 0.04%/℃

Failure protection servo valve reset spring+optional spring assist to ensure valve closure

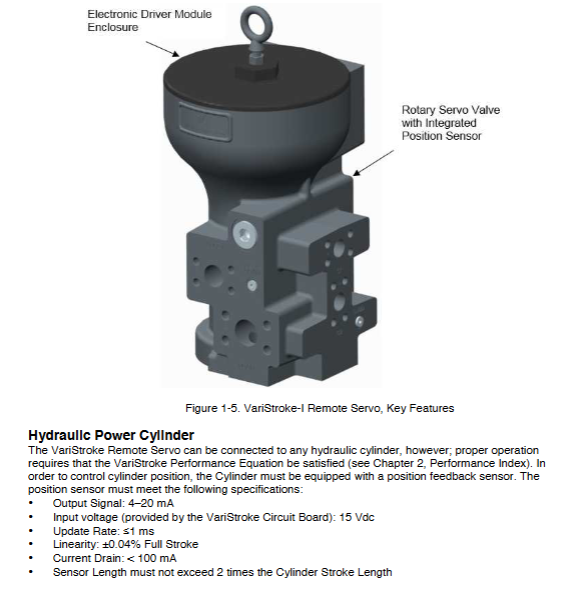

(2) Product structure type

Integrated: servo valve, hydraulic cylinder, electronic drive module integrated design, easy installation, suitable for spacious scenarios

Remote: The servo valve and hydraulic cylinder are installed separately, with a maximum distance of 3m, suitable for limited space scenarios, and attention should be paid to pipeline pressure loss

Remote Servo Only: Only provides servo valves and electronic drive modules, compatible with user’s own hydraulic cylinder (must meet position sensor requirements)

Installation process

(1) Preparation before installation

Receiving inspection: Check the appearance of the equipment for any damage, and verify that the model, serial number, and order are consistent

Unpacking requirements: Keep the hydraulic and electrical interface protective covers until they are removed during installation

Environmental preparation: Ensure that the installation area is free of pollutants, away from high temperature sources (such as uninsulated steam pipelines), and reserve maintenance space

(2) Mechanical installation

Installation orientation: The hydraulic cylinder can be installed at any angle, and the servo valve must not be inverted (vertical installation is recommended)

Bolt torque: Select the bolt grade (10.9 grade) according to the aperture, with a torque range of 50-400N · m (refer to Table 3-1 for details)

Lifting requirements: Use the equipment’s built-in lifting ears for vertical transportation, and prohibit lifting the entire equipment solely through servo valve lifting ears

(3) Hydraulic connection

Pipeline requirements: Integrated type requires connection of oil supply (1.25-inch SAE Code 61 flange) and return oil (1.5-inch SAE Code 61 flange); Remote additional control port (1.0-inch SAE Code 61 flange)

Pipeline flushing: Thoroughly flush the hydraulic pipeline before installation to prevent impurities from entering the servo valve

Connection torque: Oil supply/return interface bolt torque 34-61N · m, control port 25-35N · m

(4) Electrical connection

Power Connection: Supports single power supply or dual redundant power supply, cable specification 1.5-2.5mm ² (12-16AWG), maximum wiring distance 30m

Signal connection: Shielded twisted pair cables are used for analog signals, with cable specifications ranging from 0.14-1.5mm ² (16-24AWG), and the shielding layer is grounded at one end

Grounding requirements: PE grounding (2.5mm ² green/yellow cable) and EMC grounding (>3mm ², length<46cm), torque 5.1N · m

Service Tools and Calibration Configuration

(1) Service tool installation

System requirements: Windows 7/Vista SP1/XP SP3 (32/64 bit),. NET Framework 4.0, 1GHz CPU, 512MB RAM

Installation method: Download the installation package (9927-2177 series) through the accompanying CD or Woodward official website

Connection method: Connect the device service port through RS-232 serial port, no serial port required, USB to serial converter (recommended 8928-1151 kit)

(2) Calibration process

Calibration prerequisite: Reduce the simulated demand signal to 0mA or disconnect the operation enable, and clear all fault alarms

Step 1- Stability setting: Enter the hydraulic oil supply pressure (bar), set the manual/running sleep rate, and soft seal parameters

Step 2- Travel Calibration: Optional “Find Minimum Travel” or “Find Minimum+Maximum Travel”. After calibration, the minimum offset and maximum stop position can be adjusted

Save Calibration: After completing the calibration, click “Save Calibration” to ensure that the parameters are effective

(3) Core configuration function

Input configuration: Select the demand signal mode (single channel/dual channel average/dual channel low/dual channel high), set the enable switch for operation

Output configuration: Configure alarm/shutdown relay output (NO/NC), analog output function (demand signal/actual position)

Advanced configuration: Adjust bandwidth (response speed), jitter (overcome valve sticking), Silk Buster (regularly flush servo valve impurities)

Linearization configuration: 11 point linearization table, compensating for valve flow nonlinearity, needs to be set in ascending numerical order

Maintenance and troubleshooting

(1) Common troubleshooting

Typical causes and troubleshooting measures for fault types

The device shutdown operation enable is not activated. Check that the operation enable circuit is closed and confirm that it is configured as “Used”

If the demand signal exceeds the range (<2mA or>22mA), check the analog signal wiring and adjust the signal to 4-20mA

Key fault triggers (such as position sensor failure) can be checked through service tools to access alarm logs and identify corresponding components

The positioning accuracy deviation is large, and the cleanliness of the hydraulic oil does not meet the standard. Check the cleanliness of the oil and replace the filter element

Compensate for improper needle valve settings, recalibrate stroke, and adjust stability parameters

Connecting rod misalignment>5 °, correct connecting rod installation to ensure deviation ≤ 5 °

No response (no alarm). The power supply is not connected or the voltage is too low. Check the power supply voltage (18-32Vdc) and verify the wiring

Connect the communication fault inspection service tool and restart the device

Replace the corresponding aperture shaft seal kit (refer to Table 7-1) for hydraulic leakage seal wear and tear

The pipeline interface is not tightened. Re tighten the interface bolts according to the specified torque

(2) Maintenance operation

Shaft seal replacement: Select the corresponding kit (4-inch: 8935-1216-10; 10 inch: 8935-1216-25) according to the aperture, and install the seal strictly according to the diagram

Servo valve/hydraulic cylinder replacement: Contact Woodward authorized service organization and refer to manual 26836 to follow the replacement process

Long term storage: Clean the surface of the equipment, remove the hydraulic oil, seal the interface, store in an environment temperature of -40 to 85 ℃, avoid moisture