WOODWARD VariStroke Hydraulic Power Cylinders

The core positioning is a heavy-duty hydraulic power cylinder designed specifically for extremely hazardous environments, compatible with Woodward VariStroke series servo valves/slide tables, used for steam turbine valve control

Application scenarios and adaptation relationships

(1) Core applications

Target areas: Oil and gas, petrochemical, and power generation industries

Control objects: steam turbine control valve, valve frame, trip throttle valve (T&TV)

Adaptation to working conditions: extremely hazardous environments (Zone1/Zone2), low-pressure hydraulic systems (relying on turbine lubricating oil)

(2) Adaptation components

Compatible with VHPC type core requirements for compatible products

VS-I servo valve double acting pressure acts on both sides of the piston

VS-II servo valve double acting pressure acts on both sides of the piston

VS-GI servo valve single acting pressure only acts on one side of the piston

VS-DX hydraulic slide table single acting pressure only acts on one side of the piston

Product Core Features

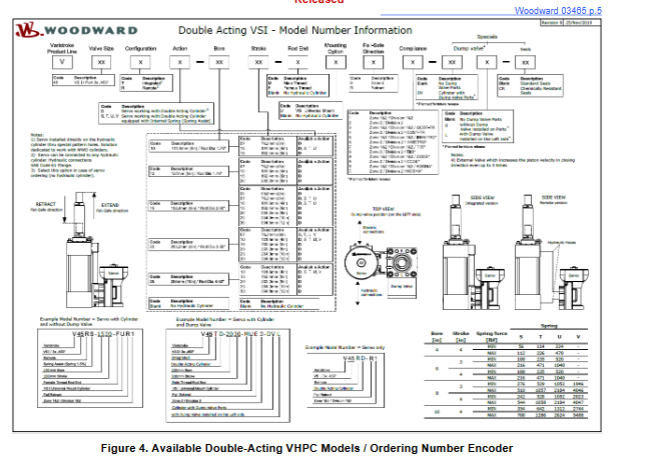

(1) Structure and configuration types

Configuration Type Core Features Applicable Scenarios

The double acting model does not have a quick release valve/port option, and the pressure driven piston moves in both directions with the VS-I/VS-II servo valve in the conventional control scenario

Single acting models can choose built-in reset springs, pressure driven+spring reset with VS-GI/VS-DX for safety control scenarios

The single acting discharge valve model integrates a fast discharge valve, which can quickly relieve pressure in scenarios where high-speed switching or separation of control/safety systems is required

Single acting discharge valve port model with reserved discharge valve interface, supporting users to self configure redundant trip components for high critical applications (dual/triple redundant trip requirements)

(2) Key functional highlights

Side load tolerance: Supports continuous side load up to 5% of the output force. Through high-precision bearings and triple sealing technology, it reduces shaft seal wear, avoids oil leakage, and solves the pain points of side load caused by the arc-shaped movement of the connecting rod

Flexible configuration options: Single acting models can choose whether to integrate reset springs, quick release valves, and release valve ports; The position sensor supports MLDT (high precision) or LVDT (conventional precision) to meet different precision requirements

Extreme environment adaptation: chrome plated piston rod, protective feedback sensor, stepped buffer design, matched with IP66 protection level, suitable for extreme working conditions such as high temperature and multiple impurities

Safe and reliable design: The rapid discharge valve has a fully open time of less than 250ms, supports direct drive of the turbine shutdown system, and achieves emergency pressure relief; Tested one by one before leaving the factory, with an 18 month warranty provided

(3) Comparison of Position Sensor Parameters

Sensor type, power supply/excitation parameters, output parameters, linearity, core advantages

MLDT 20.4-28.8Vdc @ 100mA 2-channel 4-20mA, maximum load 500 Ω± 0.02% full stroke high-precision, dual redundancy, suitable for high temperature environment of 85-105 ℃

LVDT 3.0VRMS @ 5000Hz voltage ratio output: (Va Vb)/(Va+Vb)=± 0.5VRMS ± 0.5% full stroke conventional accuracy, suitable for ordinary working conditions

Key specification parameters

(1) Environmental and Protection Parameters

Parameter values

The working environment temperature ranges from -40 ℃ to+105 ℃ (-40 ℉ to+221 ℉), depending on the fuel supply temperature

Working oil temperature+15 ℃~+70 ℃ (+59 ℉~+158 ℉)

The impact resistance performance complies with US MIL-STD-810C method 516.2 (10G peak, 11 millisecond duration)

Anti vibration performance meets US MIL-STD-810F M514.5A (0.015 G ²/Hz, 10-500Hz)

Protection level IP66 (IEC/EN 60529)

(2) Hydraulic parameters

Parameter requirements

Working pressure range: 3.44 bar~34.5 bar (50 psi~500 psi)

Oil type: mineral oil, synthetic oil, or Fyrquel EHC base oil

Recommended maximum oil cleanliness ISO 4406 code 20/18/16 level (nominal 24-40 μ m, β 75)

Recommended oil viscosity is 20-100 centixtles

Interface standard hydraulic ports comply with SAE J518 Code 61

Maximum return oil pressure 2 bar (29 psi)

(3) Quick release valve parameters (single acting with valve model)

Parameter values

Supply voltage 24Vdc

Power consumption of 20W

Full open time<250 milliseconds

Full closing time<2.0 seconds

Compliance certification

Regional/Standard Certification Content

European (CE) EMC Directive 2014/30/EU; ATEX Directive 2014/34/EU (Zone1: II 2 G Ex db IIB T4 Gb; Zone2: II 3 G Ex nA IIC T4 Gc)

Other European Standard Machinery Directive 2006/42/EC (partially completed machinery); Pressure Equipment Directive 2014/68/EU (SEP category)

International IECEx certification (Zone1: Ex db IIB T4 Gb; Zone2: II 3 G Ex nA IIC T4 Gc)

North American CSA certification (Class I, Div.1 Groups C&D T4; Class I, Div.2 Groups A-D T4), applicable to the United States and Canada