Woodward DSLC-2 Digital Synchronizer and Load Controller

Basic Information

Core positioning: Integrated controller for synchronization, load, reactive power, power factor, and process control of three-phase AC generators

Applicable scenarios include isolated operation, parallel operation of power grids, and adaptation to industrial computer rooms, ships, and other scenarios

An independent overspeed/overtemperature/overpressure shutdown device is required as a prerequisite for safety, and unauthorized modification of parameters is prohibited

Detailed explanation of core functions

(1) Synchronous control

control mode

Operation mode: Execute synchronization and output circuit breaker closing command

Check mode: Synchronize matching but do not output closing command

Allow mode: Only verify synchronization conditions, manually control speed/voltage

Off mode: Sync function disabled, manual operation

Key functions

Synchronization methods: phase matching (fast synchronization), slip frequency synchronization (ensuring forward power)

Non voltage busbar closing: supports single segment/multi segment closing, avoids conflicts through network arbitration

Voltage matching: Automatically adjust the generator voltage to the bus voltage window (default 0.5%)

Automatic Resynchronization: After the circuit breaker is accidentally disconnected, it can be retried infinitely to close (parameter 7514 needs to be enabled)

Core parameters

Slip frequency offset: 0.02-0.49Hz (default 0.18Hz)

Maximum phase window: ± 60 ° (default ± 7 °)

Circuit breaker delay: 40-300ms (default 80ms), matching the circuit breaker closing time

(2) Load control

control mode

Core purpose of mode triggering conditions

CB Aux in droop mode is disconnected, and there is no RUN/CHECK command for single machine operation or parallel stable operation

Constant frequency load sharing CB Aux closure, load/UNload closure, base load/process control disconnection, multi machine parallel load sharing

Basic load mode CB Aux+Load/UNload+Basic load input closed fixed load operation

Process control mode CB Aux+Load/UNload+Process control input closed tracking process signal (such as inlet and outlet power)

Key functions

Soft loading/unloading: Slope rate 0.01-100%/s (default 3%/s), supports pause (DI09)

Reverse power protection: instantaneous tripping (-50~-1% rated power) or delayed tripping (0.1-20s) can be set

Load limit: High/low load limit (0-150% rated), triggering alarm/relay output when exceeding the limit

Core parameters

Sag coefficient: 0-100% (default 3%)

Unloading trip level: 0.5-99.9% (default 3% rated power)

Load sharing gain: 0.00-100.00 (default 0.50)

(3) Reactive power/PF control

control mode

VAR control: maintain the set reactive power (kvar)

PF control: Maintain the set power factor (-0.5~0.5, default 0.5)

Disable mode: Only retain voltage matching, return to initial voltage bias after matching

Key functions

VAR sharing: When multiple machines are connected in parallel, the reactive load is evenly distributed proportionally

Voltage fine-tuning: Compensate for voltage deviation through PID and stabilize system voltage

Reactive power limit: The reactive power output of the generator is limited to -10%~100% of the rated reactive power (parameter 1758)

Core parameters

Reactive droop coefficient: 0-20% (default 0%)

VAR sharing gain: 0.00-100.00 (default 0.50)

PF reference: -0.999~0.999 (default 0.50)

(4) Process control

Adaptation scenarios: cogeneration, power grid import and export control, pressure/liquid level maintenance, etc

Key functions

Signal input: Supports analog signals such as 0-20mA/4-20mA/0-10V, and can be configured with engineering units (kW/℃/kPa, etc.)

PID control: proportional gain 0.01-100.00 (default 2.00), supports direct/indirect actions

Process filtering: 0-8 levels (default 0 level), suppresses noise signal interference

Core parameters

Process reference: -999999.9~999999.9 (default 0.0)

Reference lifting rate: 0.01-20.00%/s (default 0.10%/s)

Process load sharing coefficient: 1-99% (default 10%)

Hardware and Communication Configuration

(1) Hardware interface

Measurement input

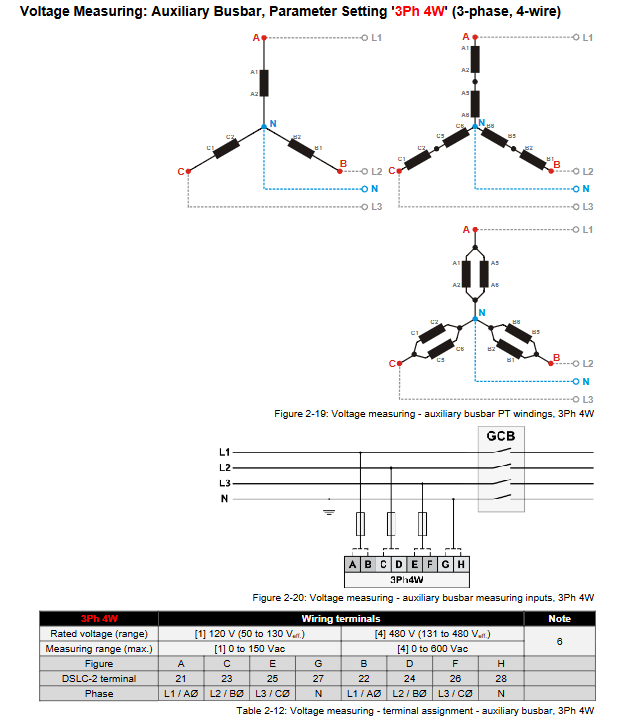

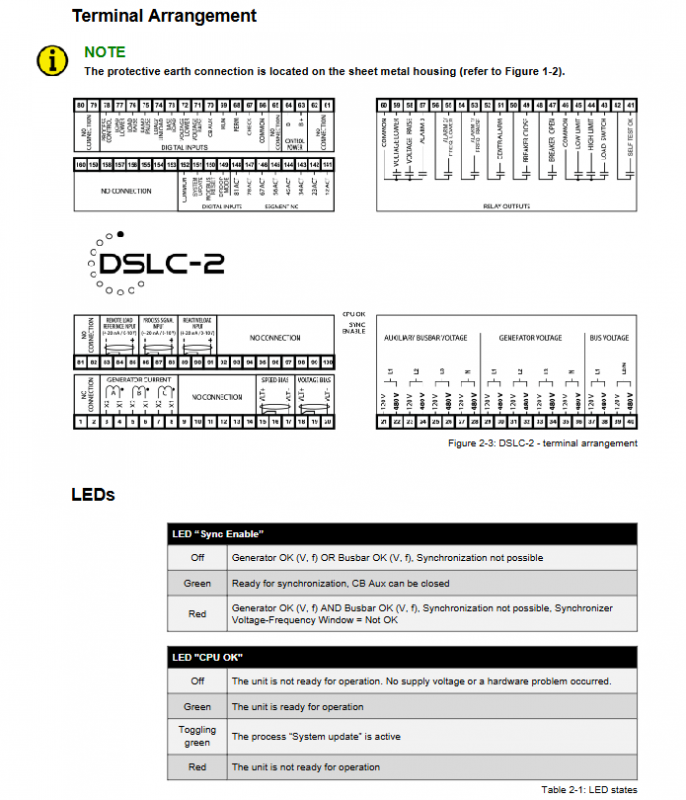

Voltage measurement: Generator (3Ph 3W/4W/4W OD), Bus (1Ph 2W/3Ph), Auxiliary Bus (3Ph 3W/4W)

Current measurement: Generator L1-L2-L3 or single phase to ground, CT ratio 1-32000A/x

Power measurement: supports active power (kW), reactive power (kvar), apparent power (kVA), and PF measurement

I/O interface

Type, quantity, key specifications

Discrete Input (DI) 23 channels support positive/negative signals, with a wire diameter of ≥ 2.5mm ²

Relay output (DO) 12 normally open contacts, used for alarm, circuit breaker control, etc

Analog input (AI) with 3 channels supporting 0-20mA/4-20mA/0-10V/1-5V

Analog output (AO) with 2 speed biases and voltage biases, supporting ± 20mA/± 10V

(2) Communication interface

serial communication

RS-232 (Serial 1): ToolKit configuration (ServLink protocol) Modbus RTU, Baud rate 9.6-115kBd

RS-485 (Serial 2): Modbus RTU slave, supports half duplex/full duplex, slave ID 0-255

Ethernet communication

Dual Ethernet ports (A/B): Supports single mode/redundant mode, configurable IP address (subnet mask 255.255.255.0)

Protocol: Modbus TCP, UDP (device to device communication), up to 10 TCP/IP connections

Redundancy function: In the event of a single network failure, the redundant network will automatically take over and trigger a communication alarm

System networking and segmentation

Network scale

Up to 32 DSLC-2s (generator side) and 16 MSLC-2 (grid/tie circuit breaker side)

Up to 8 segments, supporting two modes of bus segmentation/equipment segmentation

Segmentation rules

The segment numbering needs to be configured in linear order and can be closed into a circular shape

Up to one MSLC-2 can be used as the main controller within the same segment (priority given to the device with the smallest number)

Segmented recognition through DI13-DI20 (segmented activation signal), supporting cross segment non pressure closing

Safety and Diagnosis

Safety Specifications

Electrostatic protection: Discharge before contacting PCB, do not touch components, support 85kV electrostatic spraying

Electrical safety: PE grounding (wire diameter ≥ 2.5mm ²), power circuit connected in series with 6A slow melting fuse

Wiring taboos: CT secondary side must not be open circuited, voltage input must not be short circuited, and different signal types should be wired separately

Diagnostic function

Alarm types: frequency/voltage/load overload, communication failure, missing members, circuit breaker failure, etc

Diagnostic tool: ToolKit real-time monitoring, trend analysis, event recording, supports CSV export

Counter: Operating hours, active/reactive energy counter (can be preset and reset)