Woodward MicroNet ™ Plus modular digital control system

Product basic information

Product Name MicroNet ™ Plus digital control system

Core positioning: Special modular control for prime mover, supporting redundancy/single configuration, balancing simple and complex scenarios

Suitable for prime mover gas turbines, steam turbines, water turbines, diesel/gas engines

Target industries include power generation, oil and gas exploration, ship transportation, and process industry

Hardware configuration and specifications

(1) Core hardware components

Component specification details

CPU Configuration – Model: CP5-200 (supports 8 chassis, redundant Ethernet/CAN, suitable for I/O intensive scenarios), CP5-200L (single chassis, single Ethernet/CAN, suitable for limited I/O scenarios)

-Redundancy mode: primary/backup architecture, failover<1ms, memory synchronization, does not affect the operation of the prime mover

-Single/Redundant Upgrade: A single CPU can be upgraded to a redundant configuration by adding a second CPU and software modification

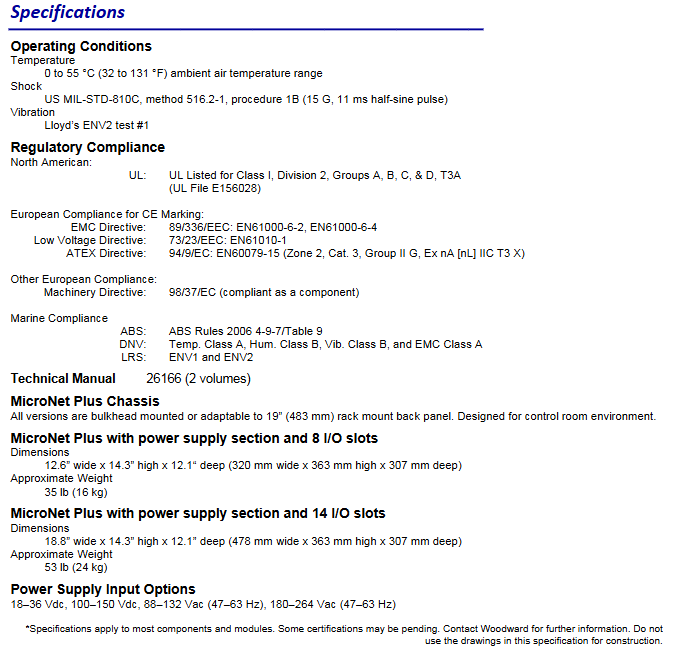

Chassis Specifications – Full Size: 14 VME slots, including 4 power slots, dimensions 478 × 363 × 307mm, weight 24kg

-Narrow size: 8 VME slots, including 4 power slots, size 320 × 363 × 307mm, weight 16kg

-Installation method: Wall mounted or 19 inch rack compatible

Power configuration – Input options: 18-36Vdc, 100-150Vdc, 88-132Vac (47-63Hz), 180-264Vac (47-63Hz)

-Configuration mode: single power supply or redundant power supply combination

I/O Module – Types: Analog, Discrete, Dedicated Module, Supports Single/Dual/Triple Configuration

-Core features: Hot swappable (continuous power replacement), high isolation between channels, partially “smart modules” (with built-in microcontroller, self diagnosis+online calibration)

-Timestamp: 1ms resolution for discrete I/O events, 5ms resolution for analog I/O and software variables

(2) Environment and Certification

Category specific parameters

The working environment temperature is 0-55 ° C (32-131 ° F), the vibration complies with Lloyd’s ENV2 standard, and the impact complies with US MIL-STD-810C (15G, 11ms half sine pulse)

Compliance Certification – North America: UL Class I Division 2 (Groups A/B/C/D, T3A)

-Europe: CE (EMC/Low Voltage/ATEX Directive) ATEX Zone 2(Cat.3,Group II G)

-Ship: ABS Rules 2006、DNV(Temp Class A/Hum Class B/Vib Class B/EMC Class A)、LRS(ENV1/ENV2)

Core functions and software

(1) Control and programming functions

Detailed description of functional categories

Core control capabilities include speed/load control, anti surge control, combustion control, temperature/process control, system sequence control, auxiliary equipment control, alarm/shutdown annunitor

Programming Environment – Tools: GAP ™ (Graphic application programming tool), supporting functional block diagrams, sequential functional diagrams, ladder diagrams

-Simulation: NetSim ™ Simulation environment, compatible with process model testing programs, reducing debugging time

-Operating System: VxWorks ® Real time system, supporting multiple rate groups (up to 5ms critical control loop, slow rate group adapted to non critical logic)

Key feature – Certainty: Control logic execution is not affected by program load or code modifications, and dynamic performance is predictable

-Time synchronization: SNTPv4 compatible, synchronization error with external time sources<1ms

(2) Communication and Expansion Capability

Category specific parameters

Supports Ethernet protocol TCP/IP、UDP/IP、OPC DA 3.0/AE 1.0、Ethernet Global Data(EGD)、Modbus RTU/ASCII( Ethernet/serial port) CANopen、 Customize proprietary drivers

Scalability – Chassis Expansion: The host chassis can connect up to 7 expansion chassis through real-time network, supporting fiber optic communication (up to 2km)

-Distributed I/O: Compatible with Woodward LinkNet ® Module and third-party CANopen/Ethernet/serial port distributed I/O

Service tools Control Assistant (03201), Monitor GAP (03306), support data graphic display, logging, trend analysis, event recording, X-Y plotting

System advantages and value

High reliability: redundant CPU/power supply, module self diagnosis, online calibration, suitable for key prime mover control scenarios

Flexibility: Modular I/O combination, multiple programming methods, multi protocol communication, seamless adaptation from simple to complex scenarios

Maintainability: Hot swappable modules, remote diagnostics, simulation testing, reducing downtime and debugging costs

Real time performance: fastest 5ms control loop, 1ms event timestamp, meeting the high-precision control requirements of the prime mover