Woodward MicroNet ™ Simplex/Plus digital controller

Basic Information

Product series MicroNet Simplex (single CPU), MicroNet Plus (dual CPU redundancy)

Core positioning: full lifecycle control of the prime mover (start-up, operation, monitoring, shutdown)

Suitable for gas turbines, steam turbines, diesel engines, gas engines, and water turbines

Certification qualifications UL/cUL, CE, CSA, EAC, ABS (Classification), LR (Classification) ATEX Zone 2

System hardware configuration

(1) Chassis specifications

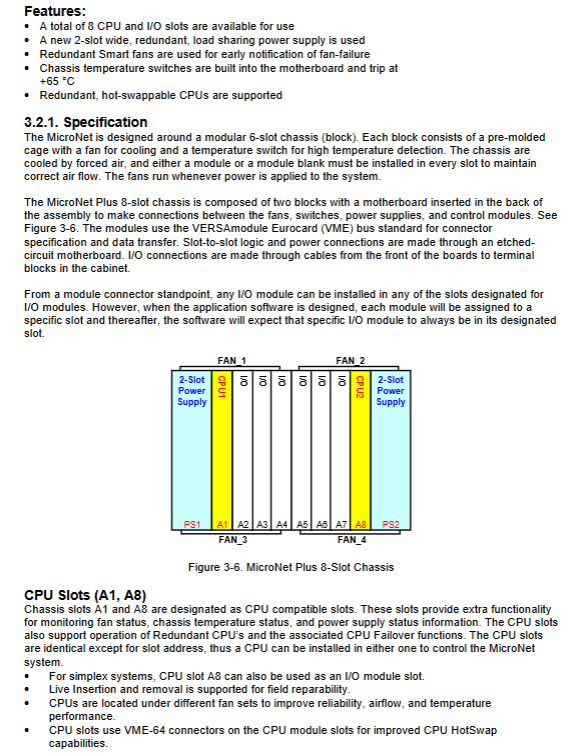

Specification: 14 slot chassis, 8 slot chassis

Slot distribution: 2 power slots+2 CPU slots+10 I/O slots, 2 power slots+2 CPU slots+4 I/O slots

Size (W × H × D) 356 × 340 × 178mm, suitable for small installation scenarios

Redundant intelligent fans for heat dissipation (6/14 slots, 4/8 slots), redundant intelligent fans for 65 ° C over temperature alarm (4), 65 ° C over temperature alarm

Grounding of chassis PE, installation of screw grounding (M4/# 8-32) is the same as 14 slot chassis

(2) Core module parameters

① CPU module

Model P1020 PowerPC CP5-200 (Motorola)

Processor 800MHz dual core MPC5200

Storage 512MB RAM+768MB Flash 128MB DDR RAM+64MB Flash

Communication interfaces: 4 Ethernet (2 × 1000Mbps), 5 CAN, 1 USB, 2 Ethernet, 2 CAN, 1 RS-232/485

Working temperature: 0 ° C~55 ° C -40 ° C~85 ° C

Redundancy Support (Slot A1/A14) Support (Slot A1/A8)

② Power module

Input specifications 24Vdc (18-36Vdc) 110Vac/dc (88-132Vac/100-150Vdc) 220Vac (180-264Vac)

Output power 600W 1250VA (AC)/600W (DC) 1250VA

output voltage 24V@12A The 5V@32A 、 5V pre charge @ 3A same left same left

Redundancy feature dual module load sharing, supporting cold plugging with same left and same left

Protection function: Input overvoltage/undervoltage, over temperature, and output short circuit protection are the same as left and left

③ I/O module

Key parameters of module type

Discrete I/O (48/24 Combo) with 48 DI (optically isolated, 18-32Vdc) and 24 DO (relay output), update time 5ms

Discrete DI (48Ch) 48 channel optically isolated input, supporting internal/external 24V power supply, input current 3mA@24Vdc

Discrete DO (64Ch) 64 channel open drain output, compatible with 16Ch/32CH relay modules, maximum load 2A@250Vac

Speed sensor module with 4 inputs (optional MPU/Eddy/Prox), frequency range 1Hz~25kHz, accuracy 0.01%

Analog I/O (24/8) with 24 channels of AI (4-20mA/0-5V) and 8 channels of AO (4-20mA), with a resolution of 16 bits and an accuracy of 0.1%

④ Communication module

Module type functional parameters

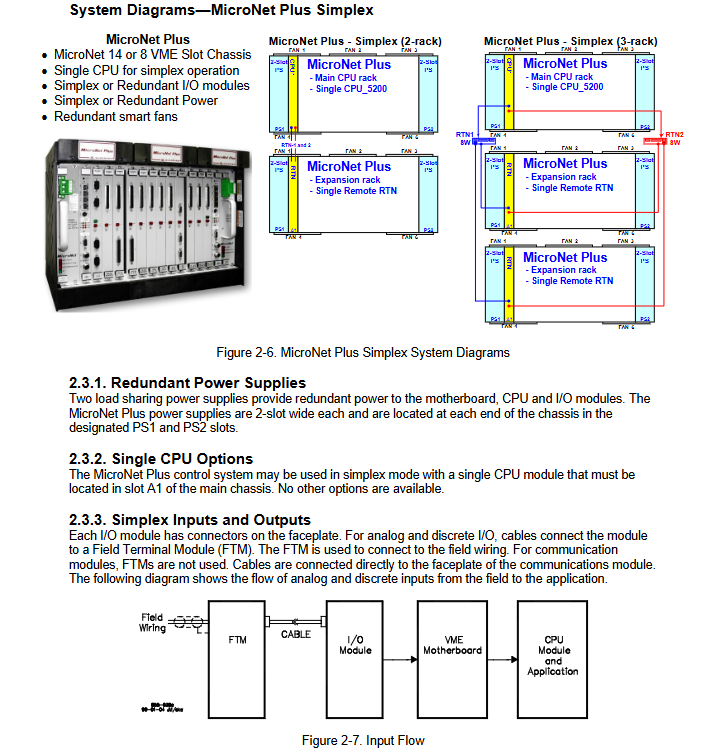

Remote RTN supports rack expansion, copper cable 30m/fiber optic 2km, up to 8 racks interconnected

SIO module with 4 serial ports (2 x RS-232, 2 x RS-232/422/485), baud rate of 110Bd~57.6kBd

Core functions and features

(1) Control function

Core control: speed control, load distribution, sequence control, surge control, auxiliary system control

Monitoring and alarm: over temperature/over pressure/over speed monitoring, module fault alarm, trend recording

Redundancy guarantee: CPU redundancy (automatic fault switching), power redundancy (load sharing), I/O redundancy (dual sensors/dual modules)

(2) Communication and Expansion

Communication protocols: TCP/IP, Modbus RTU, Modbus TCP, CANopen, DeviceNet

Scalability: Supports 7 expansion racks, copper cable transmission for 30m, fiber optic transmission for 2km (multimode)

Remote access: Supports PLC/DCS access via Modbus TCP, supports USB/Ethernet local configuration

(3) Safety and Compliance

Safety features: IOLOCK fault safety (output power loss), requirement for independent overspeed protection device, ESD protection

Environmental compliance: ATEX Zone 2 (explosion-proof), Class I Division 2 (hazardous area)

Electromagnetic compatibility: Complies with EN 61000 and needs to be installed in a metal cabinet

Software and Configuration

Development environment: Woodward GAP (graphical programming) Ladder Logic, Support rate group scheduling (minimum 5ms)

Configuration tools: AppManager (firmware upgrade, network configuration, fault monitoring), ToolKit (visual debugging)

Diagnostic functions: module LED fault codes, real-time status monitoring, historical fault records, remote diagnosis

Installation and maintenance

Installation requirements: The chassis should be installed vertically, with 8cm of heat dissipation space reserved above and below, and shielded cables should be grounded

Module replacement: Supports hot swapping (CPU/Remote RTN module needs to be reset first)

Maintenance cycle: The module undergoes health checks every 6 years, with an increased frequency of checks every 20 years or more