Woodward ProTech-SX Simplex System

Woodward ProTech SX Simplex System (Product Manual 26546V2, Version A) is a safety protection system for engines, turbines, and other prime movers. Its core functions include overspeed/over acceleration protection, fault monitoring, and alarm, supporting 7 configurable inputs and 3 programmable relay outputs+1 4-20mA analog output. It has two levels of password permissions (test level/configuration level) and can be configured and tested online/offline through the front panel interface or programming configuration tool (PCT). It is compatible with Modbus communication, can record multiple logs, and provide fault diagnosis. Throughout the process, it must comply with safety operating standards to avoid personal injury or equipment damage.

Core functions and system features

Protection and monitoring core

Core protection: overspeed protection (set range 0-32000 RPM), over acceleration protection (0-25000 RPM/s)

Fault monitoring: speed loss, open circuit of speed sensor, power failure, internal module failure, etc

Status indication: Front panel LED (trip red light, health green light, alarm yellow light)+remote limit switch feedback

Input/output configuration

Input: 7 configurable inputs, supporting analog (4-20mA) or discrete signal types

Output: 3 programmable relay outputs( 1A@30Vdc )1 channel 4-20mA analog output (proportional to speed)

Permissions and Security Mechanisms

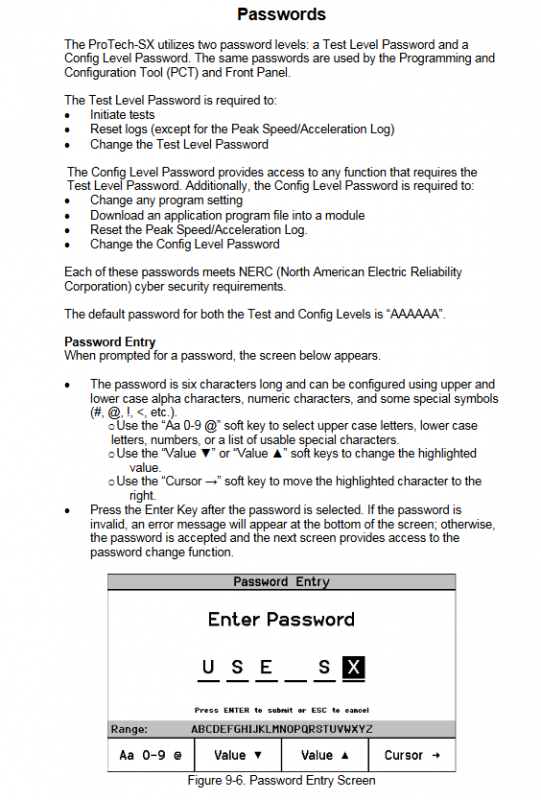

Password permission: Two level password (test level, configuration level), default is AAAAAA

Test level: Start testing, reset logs (excluding peak speed/acceleration logs), modify test level password

Configuration level: All test level functions+modify program settings, download configuration files, reset all logs

Security requirements: Compliant with NERC network security requirements, password supports letters, numbers, and special symbols (6-digit length)

Communication and Compatibility

Communication protocol: Modbus (slave mode), supports RS-232/RS-485 mode

Baud rate options: 19200/38400/57600/115200 bits/s, slave addresses 1-247

Detailed explanation of key operation modules

(1) Front panel interface operation

Key operations of module core functions

Monitor menu to view real-time data, configuration parameters, status indicators, browse RPM, acceleration, analog output, etc; View module information, date and time

Log viewing and retrieval of various event records support 8 types of logs, including overspeed/acceleration logs, trip logs, alarm logs, etc; Resettable log (password required)

Configuration menu basic parameter configuration setting speed input, startup logic, trip latch mode, analog output scaling, Modbus parameters

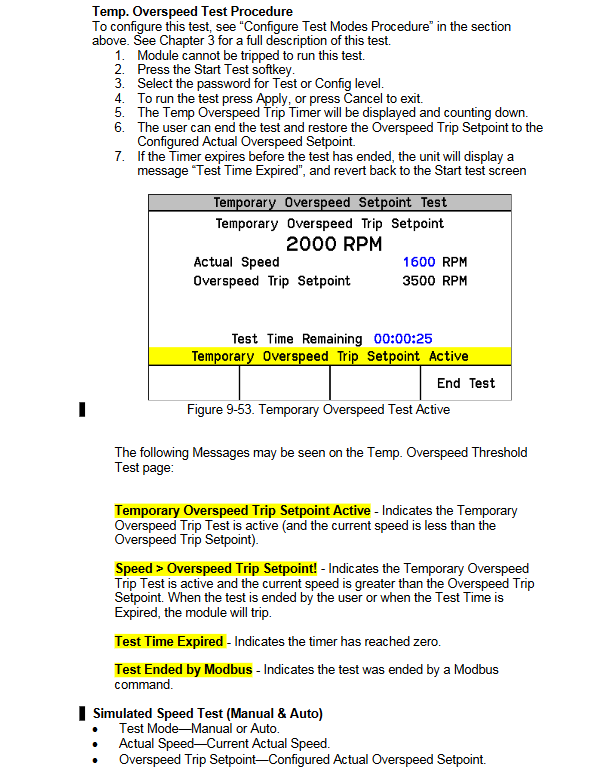

Test mode system function verification includes temporary overspeed test (<32000 RPM), simulated speed test (manual/automatic), 3 sets of user-defined tests, and indicator light test

(2) Programming Configuration Tool (PCT) Operation

PCT Basic Information

Installation method: Download from Woodward installation CD or official website (www.Woodward. com/software)

Operating environment: Based on Woodward ToolKit software, supporting Windows system

Operation level: offline mode (no device connection), testing level (online viewing/exporting logs), configuration level (online configuration modification)

core functionality

Configuration function: Modify parameters online (in device trip state)/offline, support custom logic programming such as logic gates, latches, timers, etc

Log management: View and export logs of trips, alarms, module failures, etc. (supports HTML format)

Configuration verification: Verify configuration consistency through CRC code and detect configuration errors (such as logical loops and input-output mismatches)

(3) Key configuration parameter description

Default value range for core parameters of configuration category

Speed Management Speed Redundancy Mode Single Speed/Double Redundancy Speed Single Speed

Maximum speed difference 0-32000 RPM 100 RPM

Overspeed trip setting 0-32000 RPM 1000 RPM

Start logic speed failure set point 0-25000 RPM 1000 RPM

Speed failure timeout time 1-28800 seconds 10 seconds

Simulate output 4mA corresponding to speed 0-32000 RPM 0 RPM

20mA corresponds to a speed range of 0-32000 RPM and 32000 RPM

Modbus configuration communication mode RS-232/RS-485 RS-232

Allow command writing Yes/No No

Test mode details

Test Type Test Purpose Key Parameter Operation Requirements

Temporary overspeed test verification overspeed trip function test set point 0-32000 RPM, timeout 0-1800 seconds device does not trip, test level/configuration level password required

Manual simulation speed test simulates overspeed scenario starting speed=trip set point -100 RPM, timeout 0-1800 seconds manually adjust simulation speed to trip point

Automatic simulation speed test, automatic verification of trip response, automatic ramp to trip set point without manual intervention, no timeout limit

User defined test validation supports 3 sets of tests for custom logic, configurable start/reset input, timeout time needs to be configured through PCT logic

The indicator light test verifies that the front panel LED cycle lights up the red light (trip), green light (health), and yellow light (alarm) without the need for a password, and can be executed at any time

Safety operation standards

Pre security requirements

Equipment protection: The prime mover needs to be equipped with an independent overspeed shutdown device to avoid the risk of loss of control

Personal protection: Wear goggles, safety helmets, gloves and other PPE during operation

Electrostatic protection: Discharge before coming into contact with electronic components to avoid plastic/vinyl materials coming into contact with circuit boards

Operation restrictions

Configuration modification: The configuration can only be modified when the device is in a tripped state, otherwise operation is prohibited

Password management: Password forgotten cannot be reset, need to return to Woodward for processing

Unauthorized modification: Modifications beyond the rated parameter range are prohibited, otherwise the warranty and certification effectiveness will be lost

Key issue

Question 1: What are the configuration methods for ProTech SX system and what are the core configuration limitations?

Answer: The system supports two configuration methods: ① Front panel interface configuration, which can modify basic parameters such as speed input, startup logic, and analog output; ② Programming Configuration Tool (PCT) configuration, supports online (device needs to trip+configuration level password) and offline configuration, customizable logic (logic gates, timers, etc.) and exported logs. The core configuration restrictions include: configuration modifications must be made while the device is in a tripped state; PCT online configuration requires establishing a serial communication link and entering a configuration level password; Configure to avoid logical loops (by inserting unit delay blocks for cracking); The input and output types need to match (analog inputs cannot be connected to logic gates, discrete inputs cannot be connected to comparators), otherwise configuration errors will be triggered.

Question 2: What types of log management functions does ProTech SX include, and how do I reset or export logs?

Answer: The log types include 8 types of core logs: overspeed/acceleration log, trip log, alarm log, trip cycle time log, event log (3 groups), and peak speed/acceleration log. Log operation method: ① Reset log: It can be operated on the front panel or PCT. Resetting “all logs” requires a test level/configuration level password, while resetting “peak speed/acceleration logs” only requires a configuration level password; ② Export logs: Only through the PCT tool, it supports saving logs as HTML format files, which can view detailed information such as event ID, timestamp, and first out fault; ③ Log features: The timestamp is based on the internal clock at the time of the event occurrence, and modifying the system time does not affect the historical log. A single type of log can store up to 50 events.

Question 3: What are the testing modes of ProTech SX, and what are the applicable scenarios and operational requirements for different tests?

Answer: The system includes four types of testing modes, and the applicable scenarios and operational requirements are as follows: ① Temporary overspeed test: suitable for verifying the tripping response of the actual hardware speed signal, the device speed needs to be increased to the testing set point within the test timeout (0-1800 seconds), and a test level/configuration level password is required; ② Simulated speed test (manual/automatic): suitable for verifying trip logic when there is no actual speed. Manual mode requires manual adjustment of simulated speed, while automatic mode automatically accelerates to the trip point. Both require a password and the device has not tripped; ③ User defined testing: suitable for verifying custom logic (such as tripping/alarm triggered by specific faults), requires PCT configuration to start/reset conditions, supports 3 independent tests; ④ Indicator light test: suitable for quickly verifying the function of the front panel LED, no password required, can be executed at any time, and the red/green/yellow LED lights up cyclically.