How to ensure the reliability of key QuickTrip applications?

Core Applications and Design Concepts

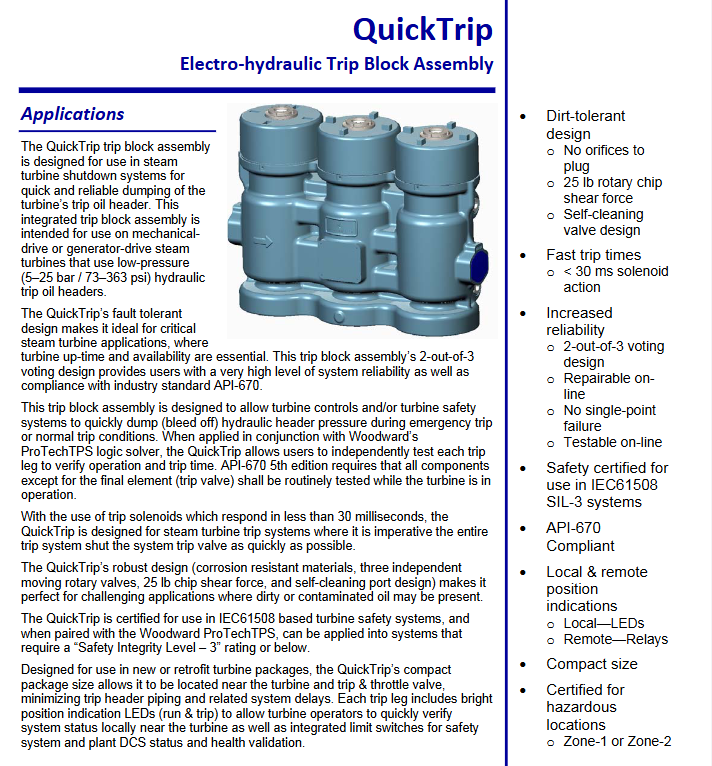

Scope of application:

Target device: Steam turbine driven by mechanical drive or generator drive

Hydraulic conditions: Low pressure trip oil main (pressure range 5-25 bar/73-363 psi)

Installation advantages: Compact structure, can be installed near the turbine and trip throttle valve, reducing pipeline length and system delay

Design Core:

Safety mechanism: 2 out of 3 voting design, 3 independent rotating solenoid valves, no component failure will cause false tripping

Redundant design: Supports 1 or 2 redundant 24Vdc power supplies, isolated discrete input signals, and no single point of failure

Core objective: To ensure the running time and availability of turbines, and meet critical application requirements

Key features and advantages

Specific description of characteristic categories

Anti pollution and anti-corrosion design – no easily clogged throttling holes, avoiding maintenance difficulties

-25 pound rotating chip force, capable of handling oil stains/impurities

-Self cleaning valve+corrosion-resistant material to prevent sticking/dragging

-Adapt to common pollutants (metal shavings, water, Babbitt alloy, ammonia, etc.) and environments with sludge and paint film in turbine oil

Fast response performance: Electromagnetic coil response time * *<30 milliseconds * *, ensuring that the tripping system quickly closes the valve

Maintainability – Online Repackability: Modular design, replaceable key components such as electromagnetic coils and electrical modules (during turbine operation)

-Online testable: equipped with Woodward ProTechTPS logic solver to achieve routine diagnosis and trip time monitoring

Status indication – local: red and green LED (running/tripping status), blue LED (power health status) (visible through the observation window)

-Remote: Integrated limit switch, supporting safety system and factory DCS status verification

Technical specification details

(1) Physical parameters

Parameter values

Dimensions (length x width x height) 46 x 63.5 x 24.5 cm (17 x 25 x 9.6 inches)

Weight 114 kg (252 lb)

Installation method in any posture (8 mounting bolt holes on the back and bottom)

Protection level IP66 (compliant with EN 60529)

(2) Electrical parameters

Parameter values

Input power supply 24 Vdc ± 10%, 3.0 A per electromagnetic coil

Discrete input isolated type, requiring 24 Vdc wetting voltage

Discrete output rated value 1 A @ 30 Vdc

Redundant design supports 1 or 2 redundant power inputs

(3) Hydraulic parameters

Parameter values

Supply pressure range 5-25 bar (73-363 psi)

Oil flow CV grade 10.0

Compatible with fluid types such as mineral oil, synthetic oil, and Fyrquel EHC base oil

Recommended oil cleanliness nominal 24-40 ppm, maximum β 75 (ISO 4406 code 20/18/16 level)

Recommended viscosity of 20-100 centixtles

Fluid port SAE J518 Code 61, diameter 31.8 mm (1.25 inches)

(4) Environmental parameters

Parameter standards and numerical values

Working temperature range -40 to+85 ° C (-40 to+185 ° F)

Working oil temperature range+15 to+70 ° C (+59 to+158 ° F)

Impact test US MIL-STD 202F, Method 213B, Test Cond. J (30 G, 11 ms half sine pulse)

Vibration test US MIL-STD 810F, M514.5A, Cat. 4 (0.04 G ²/Hz, 10-500 Hz, 2 hours per axis, 1.04 Grms)

Compliance Certification and Standards

Industry standard compliance: API-670 (5th edition, supports in operation testing) API-612、API-611

International Security Certification:

IEC61508: T Ü V certification, applicable to safety systems up to SIL-3

Hazardous Area Certification: ATEX Directive 94/9/EC (Zone-1 Category 2, Zone-2 Category 3); GOST-R certification (Russian explosive environment)

CE certification: EMC Directive 2004/108/EC、Machinery Directive 98/37/EC、Pressure Equipment Directive 97/23/EC(SEP Category)

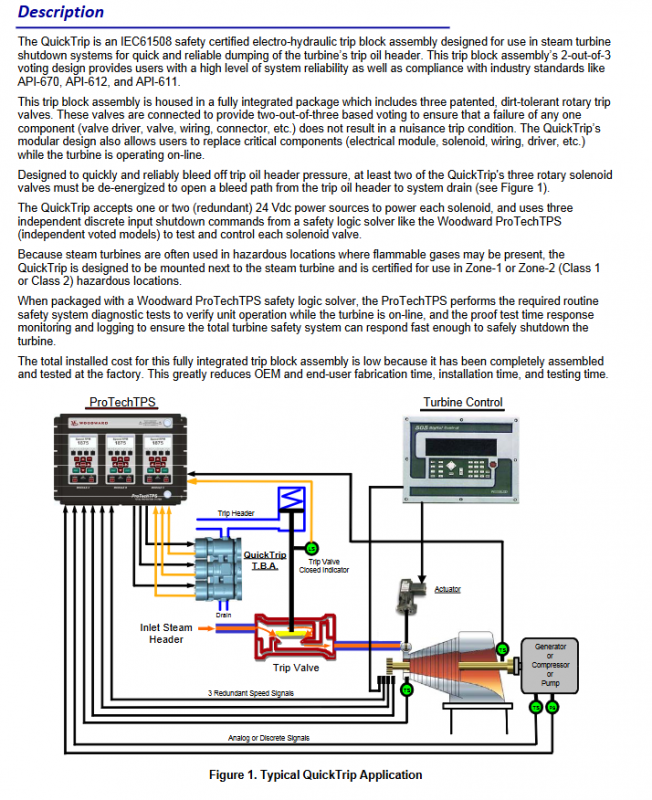

System Integration and Working Principles

Control logic: At least 2 electromagnetic coils need to be de energized before opening the channel from the tripped oil main to the system discharge

Adaptation components: Paired with Woodward ProTechTPS security logic solver, achieve:

Routine diagnostic tests during operation

Trip time response monitoring and recording

Meet the online testing requirements of API-670 for non final components (trip valves)

Signal interaction: Receive 3 independent discrete input trip commands (from safety logic solver), output position feedback signals to DCS/safety system

Key issue

Question 1: What are the core safety design and certification highlights of QuickTrip electro-hydraulic trip block components, and how do they ensure the reliability of critical applications?

Answer: Core safety design and certification highlights include: ① 2 out of 3 voting mechanism, with 3 independent rotating solenoid valves forming redundancy, no single point of failure, and no component failure causing false tripping; ② SIL-3 safety certification (T Ü V certified according to IEC61508 Parts 1-7), suitable for high safety level systems; ③ Compliant with API-670/612/611 industry standards, supporting in operation testing (compliant with API-670 5th edition requirements). These designs align with industry standards through redundant architecture, safety certification, and mechanisms to prevent the expansion of failures and ensure the operational availability and safety of critical equipment such as steam turbines.

Question 2: What are the targeted designs of QuickTrip in terms of anti fouling performance, and what pain points can it solve in steam turbine applications?

Answer: Anti pollution targeted design includes: ① no easily clogged throttle holes, avoiding maintenance problems caused by traditional components due to throttle hole blockage; ② 25 pound rotating chip force, capable of breaking impurities in oil; ③ Self cleaning valve design+corrosion-resistant materials to prevent jamming or dragging. These designs can solve common pain points in steam turbine applications: turbine oil is prone to mixing with metal shavings, water, Babbitt metal and other pollutants, and can easily produce sludge and paint film at high temperatures, causing traditional trip blocks to jam, fail or maintain frequently. QuickTrip can operate reliably in such harsh oil environments, reducing maintenance costs.

Question 3: Which key parameters in QuickTrip’s technical specifications determine its installation adaptability and operational stability?

Answer: The key parameters that determine installation adaptability and operational stability include: ① Installation adaptability: size 46 × 63.5 × 24.5cm, weight 114kg, support for any installation posture, can be installed near the turbine, suitable for new units or renovation projects; ② Environmental adaptability: Operating temperature -40~+85 ° C, IP66 protection, Zone-1/2 hazardous area certification, suitable for complex working conditions; ③ Operational stability:<30ms electromagnetic response speed ensures timely tripping, 5-25bar hydraulic pressure range, compatible with multiple hydraulic oils, meeting different system requirements; 24Vdc redundant power input+isolated discrete signal to enhance electrical system stability.