WOODWARD Vertex Digital Control

Product Overview

Product positioning: A digital control system designed specifically for axial and centrifugal compressors, providing full process control such as anti surge, performance optimization, and load distribution, supporting single compressor or multi compressor linkage scenarios.

Model classification:

|Type | Display Model | No Display Model | Core Differences|

|Single redundancy | 8200-1370/1371 | 8200-1380/1381 | Only supports independent operation|

|Dual Redundancy (VertexDR) | 8200-1373/1374/2375 | 8200-1383/1384/2385 | Supports primary backup switching to enhance reliability|

|ATEX certified version | 8200-2372 | 8200-2382 | Suitable for hazardous environments (Zone 2)|

Core advantages:

Multi control mode integration, no need for additional controllers;

Wide environmental adaptability, supporting harsh industrial scenarios;

A graphical user interface that supports local/remote configuration;

Rich communication and expansion capabilities, suitable for complex systems.

Detailed explanation of core functions

(1) Anti surge control (ASC)

Core objective: To prevent the compressor from entering a surge state (flow reversal, pressure oscillation) and avoid equipment damage.

Key mechanism:

Compressor map: supports three map types: P2=F (flow), P2/P1=F (flow), and H=F (flow), with up to 10 surge point configurations;

Control lines: Surge Limit Line (SLL), Surge Control Line (SCL) with safety margin, Boost Line (backup protection line);

Detection methods: 7 optional (flow derivative, minimum flow, exhaust pressure derivative, intake pressure derivative, speed derivative, motor current derivative, surge line crossing);

Protection actions: Surge Recovery (valve quick opening), Surge Minimum Position (SMP, valve minimum limit), Pre Pack (overshoot compensation).

Operating modes: automatic mode (valve automatic adjustment), manual backup mode (manual valve opening+automatic protection), fully manual mode (manual control+optional surge recovery).

(2) Performance Control (PFC)

Core objective: Control process parameters such as compressor suction/discharge pressure and flow rate to optimize operational efficiency.

Key components:

Main PID: Compare process variables with set values, drive throttle valves, IGVs, or speed settings;

Limiter 1/2 PID: used for motor current, pressure and other parameter limit protection;

Sequential Ramp: Supports valve position sequence control during startup/shutdown phases (Reset Position, Startup Position);

Remote control: supports remote setting values (4-20mA) and remote manual commands.

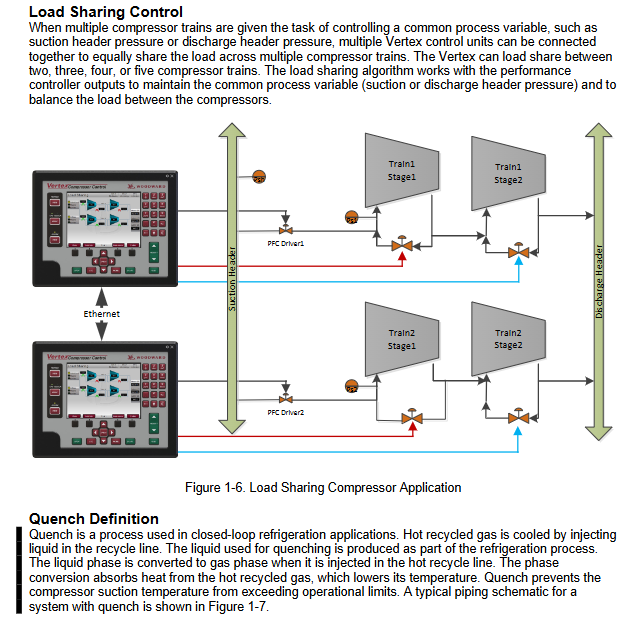

(3) Load Distribution Control (LS)

Core objective: When multiple compressors are linked, balance the load and maintain the stability of common process variables (such as manifold pressure).

Key features:

Support range: 2-5 compressors, communicating via Ethernet Port 3/4;

Balance parameters: optional WSPV (surge process variable), speed, actual flow rate;

Master Setpoint Management: Automatically elect Setpoint Master and support manual switching;

Exit mechanism: Supports multiple kick out conditions (communication failure, surge, limit activation, etc.).

(4) Other functions

Quench control: used for refrigeration compressors to maintain stable suction temperature by injecting liquid to cool the reflux gas;

Independent PID control: can be configured as an auxiliary circuit for sealing air pressure control, supporting automatic/manual mode switching;

Signal redundancy: Key signals (flow, pressure, temperature) support dual sensor redundancy configuration to enhance reliability.

Technical specifications

(1) Hardware parameters

Category specification details

Processor NXP ARM Cortex-A53 i-MX 8M (quad core 1.6GHz)

Storage 2GB DDR4 RAM+16GB eMMC+1MB FRAM

Display 8.4-inch TFT LCD (800 × 600), 10 point touch, light transmittance ≥ 85%

I/O interface AI: 8-way 4-20mA (supports loop power supply); AO: 6-way 4-20mA; actuator output: 2-channel (4-20mA/20-200mA); DI: 20 channels (24Vdc); Relay output: 8-way Form-C

Communication interface Ethernet: 4 RJ45 (10/100M); CAN: 4 (1Mbit); RS-232/485:1 channel; USB service port (disabled)

Extended I/O support for RTCnet nodes (analog I/O, RTD, DI/DO)

(2) Environmental and safety parameters

Category specification details

Working temperature band display: -30~70 ℃; No display: -40~70 ℃

Storage temperature 10~40 ℃ (recommended)

Vibration protection industrial installation: 8.2Grms; Control room: 1.04Grms

Impact protection 10G, 11ms half sine pulse (3 times on each axis)

Protection level: Front IP54 (after installation), shell IP20

Safety certifications ATEX (Zone 2), CSA (Class I, Div 2), IECEx, EMC (EN 61000)

(3) Power parameters

Power type, voltage range, maximum power consumption, isolation level

LV (DC) 18-36Vdc 77W (Vertex)>500Vrms

HV (AC/DC) 88-264Vac/90-150Vdc 73W (AC)/73W (DC)>1500Vrms

Configuration and Operation

Operation mode:

Configuration mode: Configure application parameters (requires Configure permission, compressor shutdown);

Calibration mode: Calibrate output signal (requires Service permission, compressor shutdown);

Operation mode: Normal operation control (Operator and above permissions).

User permissions are divided into four levels: Monitor (read-only), Operator (operation), Service (maintenance), and Configure (configuration). Passwords are distinguished by default (Configure: wg1113).

Configuration process:

Basic configuration: train parameters (units, pressure/temperature range), compressor layout (single/double section);

Core configuration: anti surge map, control parameters (P/I/D), I/O allocation, communication settings;

Verification: Use the Config Check function to check for configuration errors and ensure parameter validity.

Troubleshooting

Hardware malfunction: LED fault code (such as RAM test failure: 2 flashes+1 flash);

Signal failure: supports three fallback strategies: Last Good Value, default value, and intelligent calculation;

Log recording: event log (10ms timestamp), data log (can be exported for analysis).

Maintenance

Maintenance cycle:

Calibration verification: 24-36 months;

Capacitor maintenance: Backup equipment should be powered on for 3 hours every 24-36 months;

RTC battery: has a lifespan of approximately 10 years and cannot be replaced by users (requires authorized service).