HIMA HIJunctionBox on-site distributed junction box

Product basic information

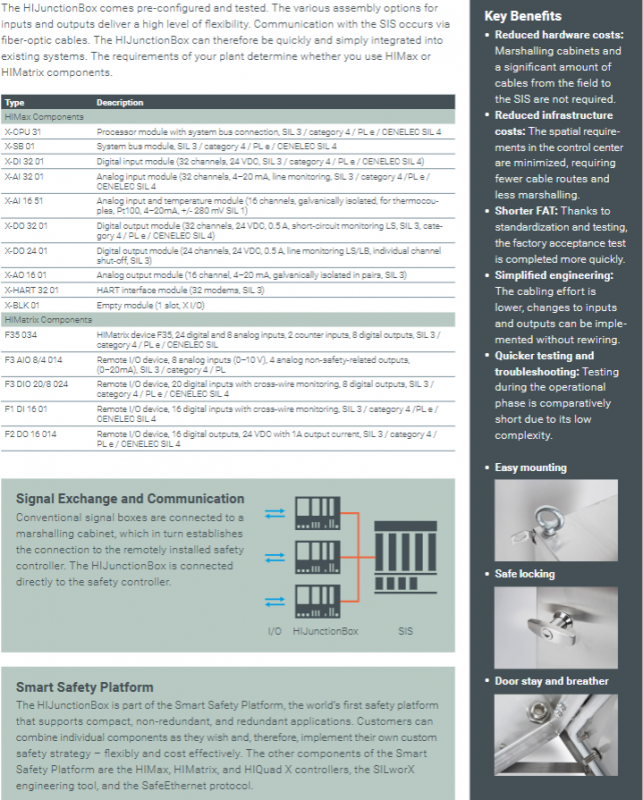

Positioning and attribution: The core component of the HIMA intelligent safety platform on the field side, used for distributed safety signal acquisition and transmission, directly connecting field devices with HIMax/HIMatrix safety controllers (SIS), replacing the traditional architecture of “field devices → marshalling cabinets → SIS”.

Core application scenario: Industrial site safety signal integration, especially suitable for Zone 2 explosion-proof environments and harsh working conditions (such as high dust and humid environments).

Hardware and Physical Specifications

Category key parameter details

Shell and protective shell material 316L stainless steel, 2mm wall thickness

Protection level IP66/NEMA 4X (compliant with IEC 60529)

Explosion proof rating suitable for Zone 2 environment

Physical dimensions (h/w/d) 1200x800x400mm

Weight 120-150kg (depending on equipment configuration, excluding packaging)

Installation and locking installation method Wall mounted

Lock design with key lock to ensure safety protection

Interface configuration: 2 power supply interfaces, supporting 100-240VAC or 110-250VDC

2 communication interfaces, supporting fiber optic (single-mode) or CAT 6 copper cable (1000 BaseT Ethernet)

Up to 96 I/O interfaces, connected through a multi cable transmission system

Compatible modules and security levels

(1) Compatible module classification (all meet SIL 3 core safety level)

Module Series Module Model Function Description Key Parameters

HIMax X-CPU 31 processor module (with system bus connection) SIL 3/Category 4/PL e/CENELEC SIL 4

X-SB 01 System Bus Module SIL 3/Category 4/PL e/CENELEC SIL 4

X-DI 32 01 digital input module 32 channels, 24VDC

X-AI 32 01 Analog Input Module 32 Channels, 4-20mA, with Line Monitoring

X-AI 16 51 Analog Input and Temperature Module 16 Channels, Galvanically Isolated, Supports Thermocouples/Pt100/4-20mA

X-DO 32 01 digital output module 32 channels, 24VDC, 0.5A, with short circuit monitoring

X-DO 24 01 digital output module 24 channels, 24VDC, 0.5A, with line monitoring (LS/LB)

X-AO 16 01 Analog Output Module 16 Channels, 4-20mA, Galactically Isolated in Pair

X-HART 32 01 HART interface module with 32 modems

X-BLK 01 empty module 1 slot, compatible with X I/O series

HIMatrix F35 034 compact device with 24 digital inputs, 8 analog inputs, 2 counter inputs, and 8 digital outputs

F3 AIO 8/4 014 Remote I/O Devices 8 Analog Input (0-10V)+4 Non Safe Analog Output (0-20mA)

F3 DIO 20/8 024 remote I/O device 20 digital inputs (with cross line monitoring)+8 digital outputs

F1 DI 16 01 Remote I/O Device 16 Digital Input (with Crossline Monitoring)

F2 DO 16 014 Remote I/O Device 16 Digital Output, 24VDC, 1A Output Current

(2) Unified standard for security level

All compatible modules meet the SIL 3 safety level, with some supporting Category 4, PL e, or CENELEC SIL 4 levels, meeting the stringent requirements of industrial safety control.

Communication and integration characteristics

Communication mode: support two mainstream communication media, adapt to different transmission distance requirements:

Fiber optic: Single mode fiber optic, suitable for long-distance signal transmission;

Copper cable: CAT 6 standard, supports 1000 BaseT Ethernet, suitable for short distance high-speed communication.

Integration advantages:

Direct connection to SIS: No need for intermediate marshalling cabinets, simplifying signal transmission links;

Pre configuration testing: Complete configuration and testing before leaving the factory to shorten on-site debugging time;

Flexible adaptation: Supports redundant or single system architecture for HIMax/HIMatrix controllers, and can combine modules as needed.

Core advantages

Cost optimization: Reduce the procurement and installation costs of marshalling cabinets, decrease the amount of cables used from the site to SIS, and minimize the space occupation in the control center;

Efficiency improvement: Standardized design shortens FAT (Factory Acceptance Testing) cycle, simplifies wiring engineering, and eliminates the need for rewiring for I/O changes;

Strong reliability: IP66 protection+316L stainless steel shell, suitable for harsh industrial environments, Zone 2 explosion-proof certification expands application scenarios;

High flexibility: compatible with multiple security modules, supports custom security policies, and adapts to the needs of industrial sites of different scales.