What are the core protection mechanisms of WOODWARD Vertex?

Product Overview

Core positioning: An integrated control and protection system designed specifically for industrial axial/centrifugal compressors, integrating control, performance optimization, and fault protection functions without the need for additional external equipment, reducing system complexity.

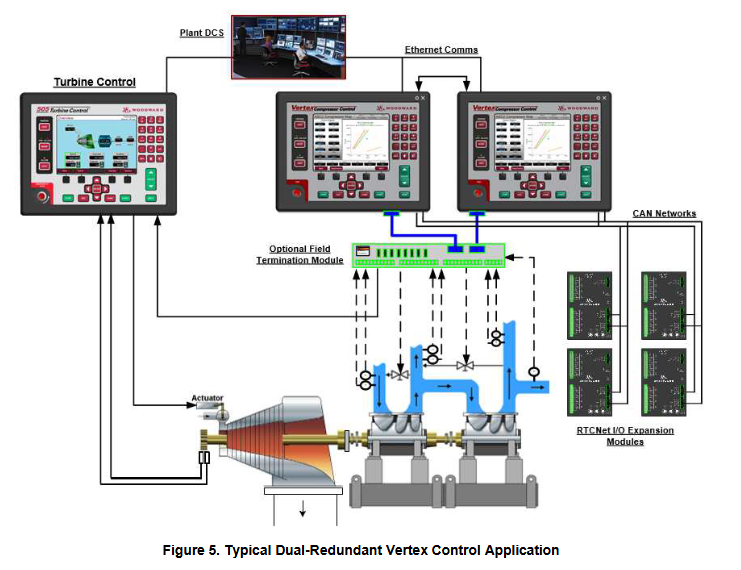

Architecture selection:

|Architecture Type | Core Features | Applicable Scenarios|

|Simplex | Single Controller Working Independently | Scenarios with General Continuity Requirements|

|Dual Redundancy | Main Controller (SYSCON)+Backup Controller (ACKUP), automatic fault switching | Critical production process, requiring high availability|

Key advantages:

Integrated design: integrating anti surge, performance control, load distribution, operation panel, and fault indication functions;

On site configurable: supports on-site modification of core functions, minor adjustments can be completed online;

Hazardous environment adaptation: certified by ATEX, CSA, etc., suitable for Class I, Div 2 and other hazardous areas;

Usability: 8-inch graphical panel with first out fault indication for simplified troubleshooting.

Detailed explanation of core functions

(1) Control function

Anti surge control (ASC)

Support 1-2 loop circuits and adapt to complex compressor structures;

Core logic: Early intervention is achieved through Boost backup line and Surge Control Line, with 7 surge detection methods (flow derivative, minimum flow, etc.);

Protection action: When surge occurs, execute Surge Recovery (valve quick opening) and Surge Minimum Position (SMP) to avoid secondary surge.

Performance Control (PFC)

Control objects: compressor suction pressure, discharge pressure, process flow rate, etc;

Auxiliary components: Performance PID+Limiter 1/2 PID (limit protection), sequential Ramp control (valve position during start/blow/stop phases);

Flexible adjustment: Supports remote analog set point (4-20mA).

Load distribution control

Supports up to 5 compressors running in parallel without the need for additional main controller hardware;

Communication method: Realize data synchronization between units through UDP protocol and automatically balance load;

Configuration features: Plug and Play, simplifying deployment.

Other control functions

Independent PID: can be used for independent control circuits such as shaft seal steam and auxiliary processes;

Sequence control: covering the entire process of position control such as starting, blowing, stopping, and zero speed.

(2) Protection function

Fault monitoring and alarm

Key parameter monitoring: bearing temperature, compressor vibration (supporting 4-20mA acceleration sensor), alarm/shutdown threshold can be set;

Equipment fault protection: CPU/memory fault detection, I/O signal fault diagnosis;

Event recording: First out fault indication, recording alarm/shutdown events with timestamps.

Surge special protection

Prevention: Surge Intervention Logic, Boost open-loop backup response;

Recovery: Surge Recovery operates quickly, responds within 50ms, and minimizes device impact;

Testing: Online anti surge valve (ASV) health testing, without affecting production operation.

Hardware and interface specifications

(1) Input/output parameters

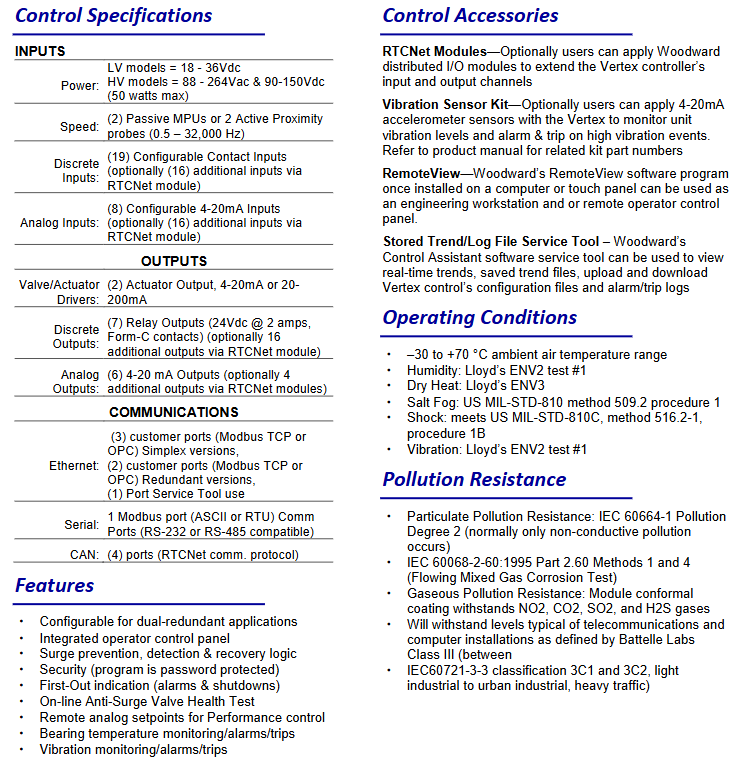

Category specification details expandable capability

Power input LV: 18-36Vdc; HV: 88-264Vac/90-150Vdc (maximum 50W)-

Speed input: 2-channel passive MPU or active proximity probe (0.5-32000Hz)-

Discrete input 19 channels, configurable contact input added 16 channels (RTCNet DI module)

Analog input 8 channels 4-20mA configurable input, adding 16 channels (RTCNet AIO module)

2 actuator outputs (4-20mA or 20-200mA)-

Relay output 7-way Form-C contacts( 24Vdc@2A )Add 16 channels (RTCNet DO module)

Analog output 6 channels 4-20mA output, 4 channels added (RTCNet AIO module)

Special input 8-channel RTD signal (RTCNet RTD module)-

(2) Communication interface

Number and specifications of interface types support protocols/functions

Ethernet single redundancy: 3 customer ports+1 service port; Dual redundancy: 2 customer ports+1 service port Modbus TCP, OPC, SNTP time synchronization

Serial port 1 RS-232/485, ASCII/RTU Modbus

CAN port 4-channel RTCNet protocol, used for distributed I/O expansion

Load allocation communication – UDP protocol (inter unit synchronization)

(3) Extension Module (RTCNet)

Module type, number of functional interfaces

AIO module simulates input/output of 8 AI+2 AO/modules, with a maximum of 2 modules

RTD module temperature signal acquisition 8-channel RTD/module

DI module discrete input extension with 16 DI channels/module

DO module relay output extension with 16 channels of DO/module

Operation and software tools

local operation

Operation panel: 8-inch graphical display, supporting parameter viewing, start stop control, and mode switching;

Permission management: Password grading (Monitor/Operator/Service/Configure), protecting program settings.

remote tool

RemoteView software: installed on computer/touch screen, enables remote operation, configuration, monitoring, and supports permission management;

Control Assistant software: Upload/download configuration files, view real-time/historical trends, export alarm/shutdown logs.

Application scenarios and compliance

Typical Applications

Motor driven compressor (1-2 circulation circuits);

Turbine driven compressor (1 loop);

Dual redundancy configuration (critical production processes requiring high availability);

Replace and upgrade the old anti surge controller.

Compliance and Environmental Standards

Regulatory compliance: CE (EMC/LVD/ATEX), CSA (Common Area/Hazardous Area) IECEx;

Environmental adaptability: salt spray resistance (MIL-STD-810), impact/vibration resistance (Lloyd’s ENV2), pollution level 2 (IEC 60664-1).