Baldor-Reliance® Integral horsepower DC motors

Product System Overview

The document revolves around Baldor Rebellion ® The brand’s overall horsepower DC motor is deployed, covering a power range of 1-500Hp, with voltage levels including 180V, 240V, 500V, etc. The protection levels include drip proof full protection (DPFG), fully enclosed no ventilation (TENV), fully enclosed fan cooling (TEFC), etc. The core is adapted to the power transmission needs of industrial scenarios and supports customized modifications to meet different environmental and working conditions.

Main product types and parameters

(1) Ordinary DC motor

Motor type, power range, armature voltage, core characteristics, applicable scenarios

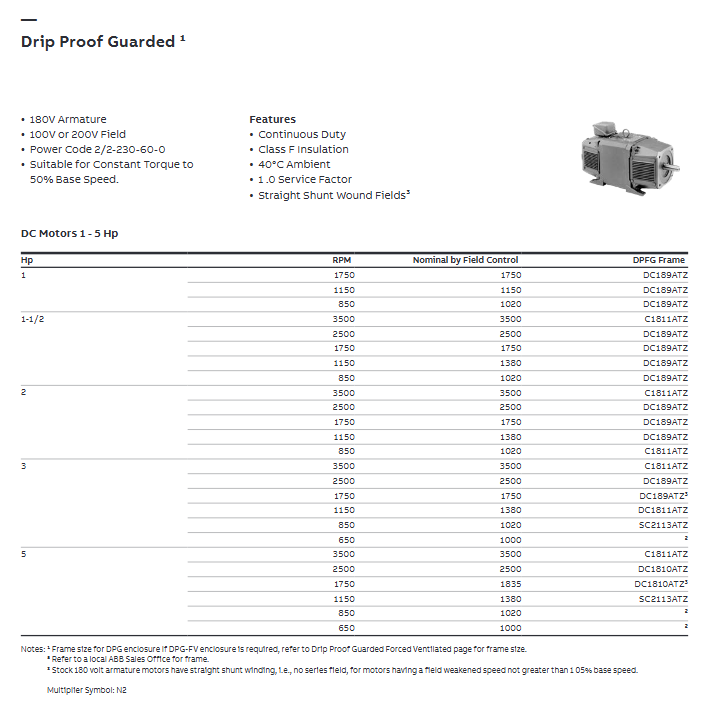

Drip proof full protection (DPFG) 1-500Hp 180V, 240V, 500V 20:1 constant torque speed range, Class F insulation universal industrial transmission

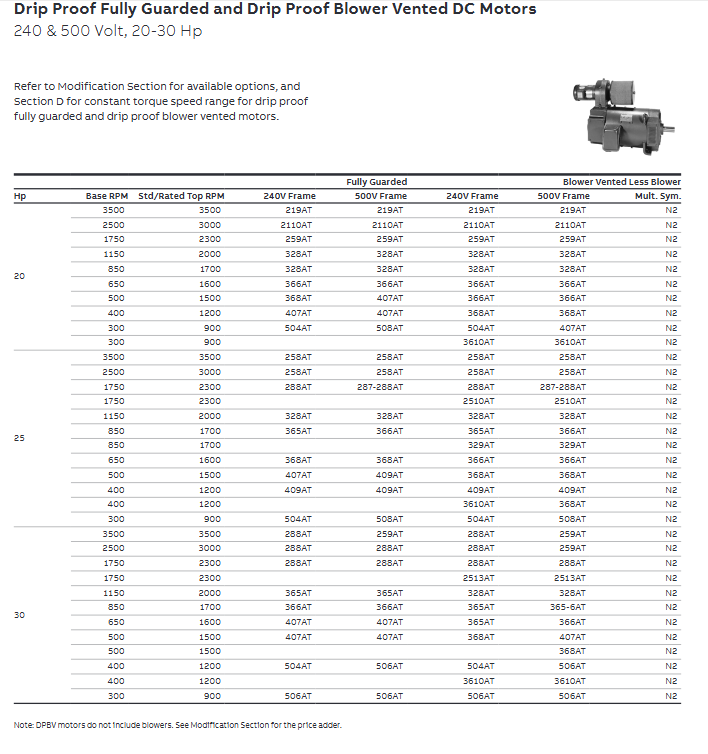

Drip proof blower ventilation (DPBV) 1-500Hp 240V, 500V without blower, requires additional high-temperature environment heat dissipation requirements

Fully enclosed non ventilated (TENV) 1-40Hp 180V, 240V, 500V dustproof and moisture-proof, compact structure, clean environment

Fully enclosed fan cooling (TEFC) 2-75Hp 240V, 500V forced air cooling, continuous operation in harsh environments for long-term operation

(2) Short time rated motor

Power range: 1-150Hp (240V), 3-500Hp (500V)

Rated duration: 1 hour, 30 minutes, 15 minutes

Core requirement: The winding temperature should be close to the ambient temperature (± 5 ° C) when starting, and the excitation voltage should be cut off when not in operation

(3) Specialized motor

Paper mill service motor: supports Class F/B temperature rise level, with special configurations such as splash proof cover and transparent handhole cover, with a power of 7.5-500Hp

Range driven motor: 240V armature, 240V excitation, compatible with multi motor drive systems, power 3-50Hp

Extruder specific motor: anti drip protection forced ventilation, including fiberglass filter, warning thermometer, power 10-400Hp

IEC DC motor: 460V armature, 310V excitation, IP23 protection, power 15.9-396kW

(4) Generator products

DC generator: 120V, 250V and other voltages, fully protected against dripping, power 0.75-170kW

Enhance magnetic generator: 230VDC output, Class H insulation, power 5-40kW, suitable for lifting scenarios

Core technical characteristics

General standards: Class F insulation level, 40 ° C ambient temperature adaptation, 1.0 service factor, direct excitation winding (partially stable direct excitation)

Structural design: commutator end locking bearing, accessory installation surface, standard shaft diameter and length (customizable)

Speed regulation performance: Ordinary motors support 20:1 constant torque speed regulation, and short-term rated motors are suitable for different load duration requirements

Protection capability: Explosion proof motors comply with Class I/II hazardous environment standards, and paper mill motors have anti-corrosion and anti drip characteristics

Customized modifications and accessories

(1) Main modification items

Environmental adaptation: High altitude (>3300 feet), high temperature (>40 ° C), low temperature (as low as -60 ° C)

Mechanical structure: sliding base, insulated bearings, special shaft materials (316 stainless steel, etc.), customized packaging

Electrical configuration: special excitation voltage, winding type (series excitation, compound excitation), thermal protection (thermometers, thermistors)

Function expansion: brake, speedometer, encoder installation, additional junction box

(2) Key accessories

Detection category: BEI, Avtron series encoders, XPY DC speedometer

Protection category: Space heater, shaft grounding brush, dust-proof seal

Connection type: enlarged junction box, cast iron junction box, terminal board

Application and adaptation instructions

Compatible power supply: Supports 230V/460V AC input, full wave rectification power supply, NEMA Type C/D standard

Industry Scenarios: Paper Mill (Wet End Operation), Lumber (Rapid Acceleration and Deceleration Requirements), Extruder (High Temperature Environment), General Industrial Transmission

Installation requirements: vertical/horizontal installation, coupling connection, belt drive (matching bearing load)