ABB MicroFlex servo drive

Core parameters of the product

Category key specifications specific parameters

Current specification: Continuous output current of 3A/6A/9A (RMS)

Peak output current 6A/12A/18A (continuous for 3 seconds)

Voltage parameter main circuit input 115-230VAC (single/three-phase), 105-250VAC wide range

Control circuit input 24VDC (compatible with 20-30V), 4A startup impulse current

DC bus voltage 305V (115VAC input)/321V (230VAC input)

Control performance control mode: torque control, speed control, position control (pulse+direction)

Maximum pulse frequency 1MHz (position control)

Feedback resolution rotary transformer 4096PPR (configurable 1024PPR), encoder up to 8MHz

Environmental adaptation working temperature 0-45 ℃ (normal), 45-55 ℃ (linear derating)

Storage temperature -40-85 ℃

Humidity limit 93% RH (no condensation)

Installation at an altitude of 1000m (with a capacity reduction of 1.1% for every 100m beyond 1000m)

Installation and wiring specifications

(1) Mechanical installation requirements

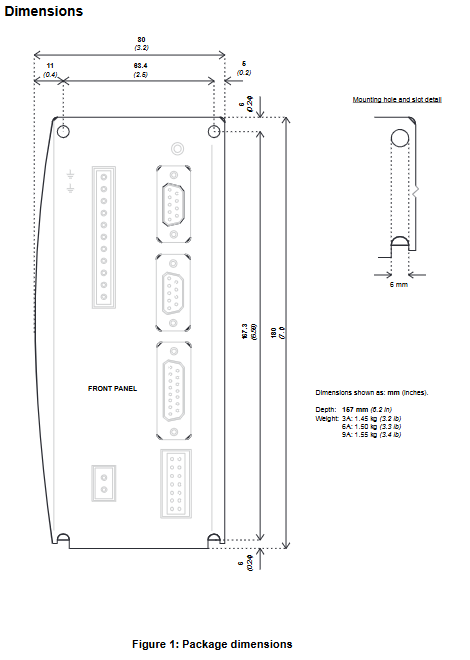

Installation method: Vertically installed on the metal backplate to ensure that the heat dissipation surface is in close contact

Spacing requirements: Side ≥ 15mm, up and down ≥ 90mm, front ≥ 60mm (wiring space)

Cooling requirement: 3A model naturally cooled; The 6A model requires forced air cooling at 1-1.5m/s; 9A model requires forced air cooling at 1-3.5m/s

Capacity reduction feature: For every 1 ℃ increase above 45 ℃, the output current is reduced by 2%

(2) Electrical wiring details

Power wiring:

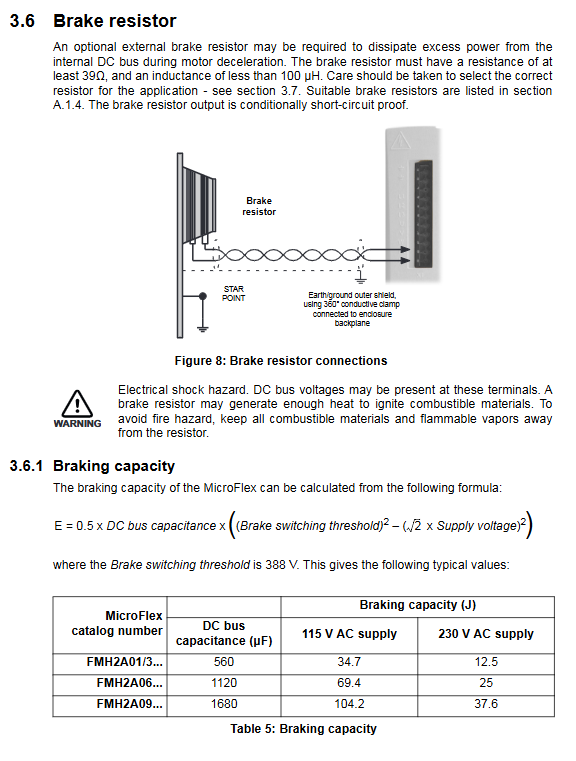

Main circuit: L1/L2/L3 connected to input power supply, U/V/W connected to motor winding, R1/R2 connected to braking resistor

Protection configuration: Recommend using Ferraz Shawmut series fuses (3A model 10A/8A, 6A model 20A/12.5A, 9A model 25A/20A)

Grounding requirements: protective grounding conductor ≥ 2.0mm ² (copper), maximum grounding leakage current 3.4mA/phase

Feedback wiring:

Incremental encoder: X8 interface (15 pins), CHA ±/CHB ±/CHZ ± differential signal, supports Hall signal input

SSI encoder: X8 interface (15 pins), Data ±/Clock ± differential signal, longest cable 30.5m

Rotary transformer: X8 interface (9 pins), REF ±/COS ±/SIN ± signal, equivalent resolution 4096ppr

Signal wiring:

Analog input: X3 interface AIN0 ±, ± 10V range, 12 bit resolution

Digital I/O: X3 interface (driver enable, universal input, pulse+direction, status output)

Serial communication: X6 interface (RS232/RS485), default 57.6Kbaud, supports multi machine networking

(3) Selection of braking resistor

Minimum resistance: 39 Ω (to avoid overcurrent damage to the driver)

Recommended models: RGJ139 (39 Ω/100W), RGJ160 (60 Ω/100W), RGJ260 (60 Ω/200W), RGJ360 (60 Ω/300W)

Requirements for Capacity Reduction: Capacity reduction is required in free air environments (for 100W models, capacity reduction is required at 25 ℃ to 80% and 55 ℃ to 70%)

Configuration and Debugging Process

(1) Software Tools

Essential software: Mint WorkBench (supporting Windows XP and above systems)

Hardware requirements: The PC requires a 1GHz processor, 512MB of memory, 2GB of hard drive, and a serial port (RS232/RS485)

Core functions: Commissioning Wizard, Fine tuning, Parameters, Scope

(2) Debugging steps

Hardware connection: The PC is connected to the driver through a serial port cable (X6 interface), and the 24VDC control power supply and main circuit power supply are connected

Software startup: Install Mint WorkBench, create a new project, scan and connect drives

Wizard configuration: Use the Commissioning Wizard to select the control mode, motor model, and feedback type, and automatically complete parameter tuning

Fine tuning optimization: Adjust the gain of the current/speed/position loop using Fine tuning tools and perform testing motion to verify performance

Parameter saving: Save configuration parameters to the non-volatile memory of the drive to avoid power loss

(3) Control mode description

Control mode signal source, core purpose, key parameters

Torque control analog input/software command constant torque output scene torque constant, current loop gain

Speed control analog input/software instruction constant speed operation scenario speed loop gain, acceleration/deceleration time

Position control pulse+direction input precision positioning scene electronic gear ratio, position loop gain

Troubleshooting and Maintenance

(1) Fault indication and handling

Key points for troubleshooting status LED fault types

Red flashing (1-12 times) corresponds to error codes (1=phase search error, 3=overcurrent, etc.). Check AXISOROR/DRIVEERROR parameters and wiring/load

Red green alternating flashing undervoltage warning. Check if the main circuit power supply is connected and if the DC bus voltage is ≥ 50V

Check the wiring of the 24VDC power supply to ensure that the voltage is within the range of 20-30V when the control power supply fails to light up

(2) Common problem solving

Communication failure: Confirm that the PC serial port selection is correct, use the “scan all serial ports” function, and check the serial port cable wiring

Driver unable to enable: Check if the X3 interface driver enable signal (6/7 pins) is valid and clear the fault status

Motor instability: Reduce the speed loop proportional gain (KVPROP) and confirm that the current loop parameters match the motor

(3) Maintenance points

Regular inspection: Check if the heat dissipation duct is unobstructed, if the temperature of the braking resistor is normal, and if the cable shielding layer is intact

Cable maintenance: The distance between feedback cables and power cables should be ≥ 76mm, avoiding parallel wiring and maintaining a 90 ° angle when crossing

Software maintenance: Regularly update Mint WorkBench version, backup drive configuration parameters

Accessories and Compliance Information

(1) Key accessories

Accessory type, model, example, function, and purpose

Cooling fan FAN001-024 provides forced air cooling for 6A/9A models, meeting UL certification requirements

EMC filter FI0029A00 suppresses electromagnetic interference and complies with CE directive requirements

The RGJ series braking resistor consumes braking energy to avoid bus overvoltage

Special cable CBL025SP-12 motor power cable/feedback cable with shielding layer

(2) Compliance requirements

CE compliance: EMC filter needs to be installed, motor cable length ≤ 30m, shielding layer grounded 360 °

UL compliance: Use recommended fuses to protect grounding conductors with a minimum of 2.0mm ²

RoHS compliance: Restrictions on harmful substances such as lead and mercury, product labeling complies with SJ/T 11364-2014 standard