Baldor-Reliance ® NEMA Super-E ® Efficient motor products

1、 Product System Overview

The document revolves around Baldor Rebellion ® NEMA Super-E ® Series of high-efficiency motors developed with NEMA Premium ® The core selling point is energy efficiency, covering the power range of 0.18kW-300kW (1/4Hp-400Hp), providing two types of protection: TEFC (fully enclosed fan cooling) and ODP (open anti drip). It is suitable for single-phase 115/230V, three-phase 208-230/460V, 575V and other voltage levels. The frame size extends from 48 and 56 to 449T, including general-purpose and HVAC, refrigeration tower, pump, unit handling and other specialized models, meeting the diverse needs of power transmission, fluid transportation, material handling and other industrial production scenarios.

2、 Core product types and key parameters

(1) Comparison of Core Parameters of Universal Motors

Protection type, phase power range, voltage level, core characteristics, framework dimensions

TEFC single-phase 0.18-3.7kW (1/4-5Hp) 115/230V capacitor start/run, dynamically balanced rotors 48, 56, 143T-184T

TEFC three-phase 0.37-300kW (1/2-400Hp) 230/460V, 575V Class F insulation, 1.15 service factor 56, 143T-449T

ODP single-phase 0.18-3.7kW (1/4-5Hp) 115/230V open heat dissipation, heavy-duty steel frame 48, 56, 143T-184T

ODP three-phase 0.75-300kW (1-400Hp) 230/460V, 575V anti drip structure, rodent screen protection 143T-449T

(2) Key configurations for dedicated models

HVAC specific motor:

Covering TEFC/ODP types, power 0.75-75kW (1-100Hp), compatible with 230/460V, 575V

Equipped with AEGIS ® The bearing protection model has Class H insulation and is compatible with variable speed drives

Features: Heavy duty steel frame, dynamically balanced rotor, installation in any direction

Refrigeration tower/chiller motor (TEAO):

Power 3.7-56kW (5-75Hp), 230/460V three-phase

Protection: Epoxy anti-corrosion coating, double sealed bearings, moisture-proof winding

Adaptive airflow speed: 1200-2000ft/min

Pump motor:

Direct connection design, including TEFC/ODP type, power 0.75-37kW (1-50Hp)

Equipped with AEGIS ® Grounding ring type: Class H insulation, oversized bearings, suitable for speed regulation scenarios

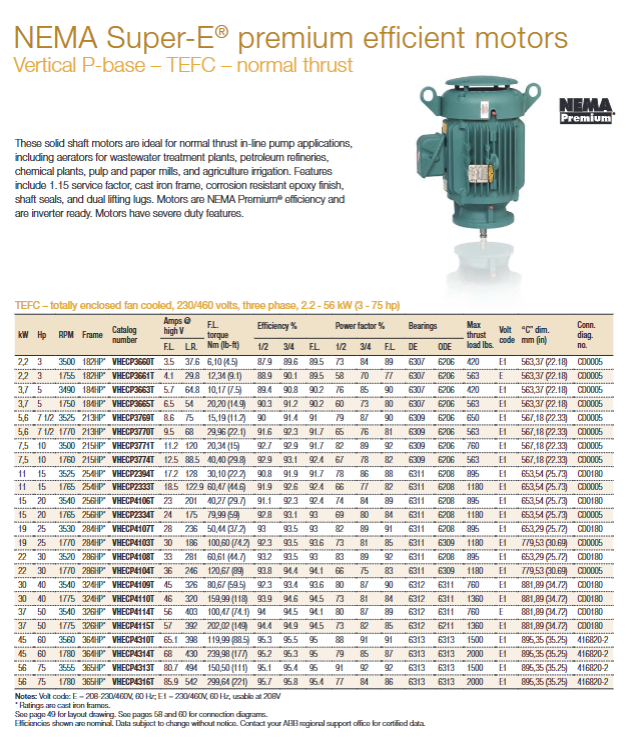

Vertical P-base model: capable of withstanding normal thrust, suitable for sewage treatment and irrigation pumps

Unit handling motor:

Power 0.37-7.5kW (1/2-10Hp), 208-230/460V, 575V

D series brake model: spring brake, manual release lever, suitable for conveyors and elevators

200V dedicated motor:

Covering TEFC/ODP types, with a power of 0.75-75kW (1-100Hp)

Features: Cast iron frame, locking end bearings, suitable for special power supply scenarios

(3) Range of key performance parameters

Performance indicator range standard configuration

Efficiency level meets NEMA Premium standards ® Standard across the entire series

Insulation Class F (some specialized models Class H) for all models

Service coefficient 1.15 (1.0 for some brake models) standard for general models

Multiple speeds available: 900RPM, 1200RPM, 1750-1780RPM, 3450-3560RPM

Warranty period of 3 years (841XL series 5 years) Full range guarantee

3、 Core Technology and Design Features

Energy Efficiency and Electrical Design:

Meet NEMA Premium requirements ® Energy efficiency standards to reduce lifecycle energy consumption

200 ° C inverter peak protection insulation system, compliant with NEMA MG1 Part 31.4.4.2, compatible with frequency converters

Silicon free wires, anti corona testing to enhance electrical stability

Mechanical and protective design:

Standard Mobil Polyrex ® EM grease has a lubrication life four times longer than ordinary grease and can withstand high temperatures up to 176 ° C

Cast iron/heavy-duty steel frame, galvanized hardware, TEFC model with anti-corrosion epoxy coating

Dynamically balanced rotor, vibration peak<38.1mm/s (some models<2.03mm/s) Installation and adaptability: Supports various methods such as foot installation, C-face installation, and footless installation The frame size is compatible with NEMA standards, and some models can adapt to multi frame installations of 56, 143T, and 145T Suitable for high altitude (>3300 feet), high and low temperature (-60 ° C to>40 ° C) environments

4、 Customization and accessory options

(1) Main customized projects

Electrical customization: special voltage (such as 200V), thermal protection (thermostat/thermistor), special winding types

Mechanical customization: insulated bearings, stainless steel shafts, sliding bases, customized shaft diameters/lengths

Environmental adaptation: anti-corrosion coating, high-altitude calibration, low-temperature start-up optimization

Function expansion: brake, encoder, speedometer, enlarged junction box

(2) Core accessories

Protection category: AEGIS ® Bearing protection ring, space heater, dust seal

Detection category: BEI/Avtron encoder, XPY DC speedometer

Connection type: cast iron junction box, terminal board, extension conduit

Braking type: Dodge “D” series spring brake (torque 2.87-23.94Nm)

5、 Authentication and Application Scenarios

Certification qualifications: UL/CSA certification, CE certification, in compliance with NEMA standards, some models have passed ASTM B117-90 96 hour salt spray test

Core application:

General industries: machine tools, conveyor belts, compressors, blowers

Architecture and HVAC: ventilation fans, air conditioning units, heat pumps

Fluid processing: water pump, oil pump, refrigeration tower, chiller

Material handling: luggage conveying, elevators, cranes, packaging equipment