Baldor FDH1A05TB-EN20 FlexDrive II AC Servo Drive

1. Product Overview

Model and basic information: Baldor FDH1A05TB-EN20 FlexDrive II AC servo drive, priced at $1895.00, with 3 units in stock, in excellent condition, suitable for speed, current, and position control of single axis rotating systems.

Core Features:

Power supply support: 115VAC single-phase, 230VAC single/three-phase, 230-460VAC three-phase (depending on the model).

Current specification: Continuous current of 2.5A-27.5A, peak current of twice the rated value (continuous for 1.25-2.4s).

Feedback methods: Supports resolver, incremental encoder, EnDat/Hiperface absolute encoder.

I/O configuration: 8 optically isolated digital inputs, 3 optically isolated digital outputs, 1 analog input, and 1 relay output.

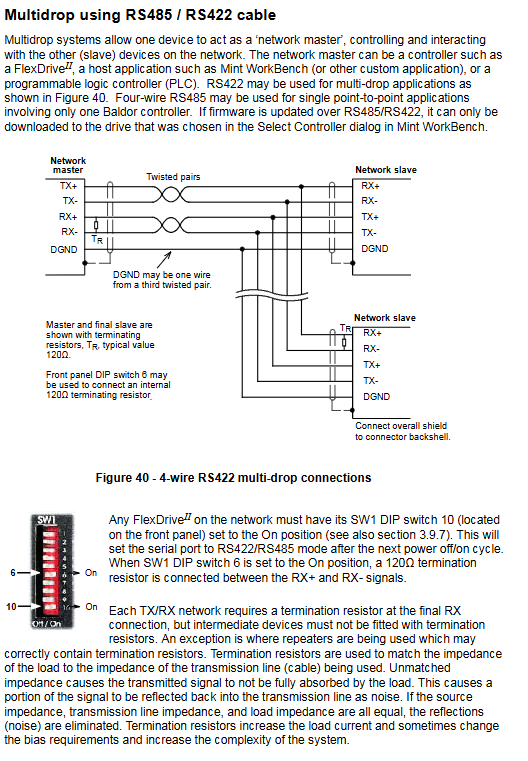

Communication interface: RS232/RS485 optional, supports MODBUS protocol, and some models support CANopen/DeviceNet/Profibus.

Applicable scenarios: Variable speed three-phase brushless AC motor control for industrial fixed equipment, prohibited for use in household appliances, medical equipment, mobile carriers, and other scenarios.

2. Installation process

2.1 Installation Preparation

Environmental requirements: temperature 0-40 ℃ (with a 2.5% reduction in capacity for every 1 ℃ increase in temperature between 40-50 ℃), relative humidity<90% (non condensing), altitude ≤ 1000m (with a 1.1% reduction in capacity for every 100m exceeding 1000m).

Hardware requirements:

Equipment/tool specification requirements

Minimum PC: Pentium III 500MHz, 128MB RAM, 50MB hard disk space; Recommendation: Above 1GHz, 1GB RAM

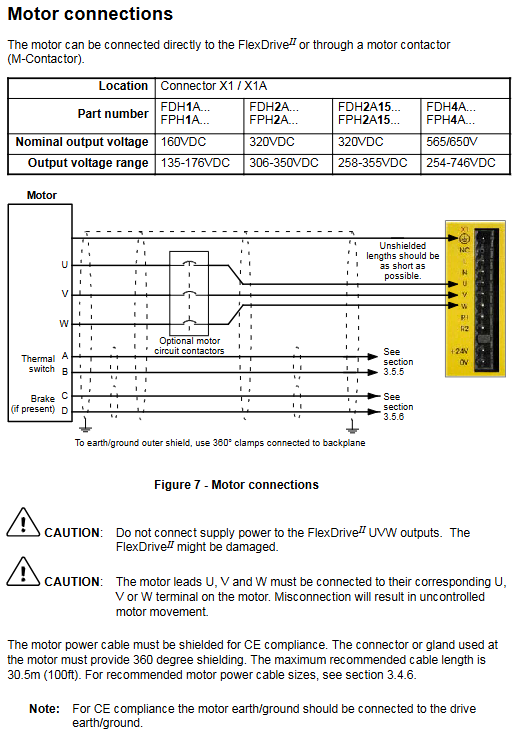

Cable motor power line (shielded twisted pair, up to 30.5m), feedback cable (shielded twisted pair, 22AWG or above)

Tools: Small screwdrivers below 3mm, M5 bolts, crimping tools

Other regenerative resistors (7.5A and above models require external installation), EMC filters (required for CE compliance)

2.2 Key Connection Steps

Mechanical installation: Vertically fixed on a non flammable surface, leaving 50mm of heat dissipation space at the top/bottom, and installed side by side with a spacing of ≥ 13mm.

Electrical connection:

Power connection: Single corresponding L/N terminals, three-phase corresponding L1/L2/L3 terminals, must be reliably grounded.

Motor connection: The U/V/W terminals correspond to the motor winding, and it is necessary to distinguish the cable pin configuration of rotary/linear motors.

Feedback connection: resolver (9-pin D-type interface), encoder (15 pin D-type interface), signal pair requires twisted pair, shielding layer single ended grounding.

Regenerative resistor: Connect R1/R2 terminals, keep away from flammable materials, and leave enough space for heat dissipation.

3. Operation and Configuration

3.1 Software Operation

Software installation: Install Mint WorkBench via CD-ROM, supporting Windows 2000/XP/Vista systems.

Debugging process:

Connect the PC to the driver (RS232 is preferred, recommended for first-time installation).

Start the Commissioning Wizard to complete the motor parameter configuration and automatic tuning.

Perform test movement: Start the motor with the command JOG. 0=10, stop with STOP. 0, and monitor the Spy window parameters.

3.2 Core Function Configuration

Control mode:

Current control: Receive torque reference signal and adjust motor current through PI controller.

Speed control: Tracking speed reference through PID controller, supporting acceleration/deceleration configuration.

Position control: Supports pulse and direction input, preset movement, point-to-point movement (exclusive to Flex+DriveII).

Preset Mobile and PLC Tasks:

Preset movement: Up to 256 sets can be stored (CAN extension required), which can be triggered through digital input or software.

PLC task: supports condition judgment and action execution (such as limit triggered shutdown), and can save configuration files (in. plc format).

4. Troubleshooting and Safety Standards

4.1 Common fault handling

Troubleshooting direction

Check the connection between the 24VDC control power supply and the AC main power supply when the status display is blank

Communication failure confirmation RS232/RS485 switch (SW1-10), cable wiring, COM port conflict

Unstable motor, re tuning current loop, reducing speed loop gain (KVPROP/KVINT)

Overvoltage fault check input voltage, increase regeneration resistance, and reduce deceleration rate

4.2 Safety Regulations

It must be operated by professionals. Before operation, disconnect the high-voltage power supply and confirm reliable grounding.

The wiring must comply with NEC/CE standards, with separate wiring for power and control lines, intersecting at a 90 degree angle.

Regenerated resistors may generate high temperatures, keep away from flammable materials; Even if the motor circuit is shut down, there may still be high voltage present.

5. Summary of Technical Specifications

Category key parameters

Power input single-phase 115VAC (75-125V), 230VAC (75-250V); Three phase 230V (75-253V), 230-460V (75-528V)

Output characteristics: Output voltage 0-corresponding to input voltage, output frequency 0-500Hz, switching frequency 8kHz

Feedback accuracy Resolver: 14 bits, ± 3 counts; Encoder: up to 4096PPR

Environmental protection with impact resistance of 10G and vibration resistance of 1G (10-150Hz)