WAGO 281-611/281-418 fuse terminal block

WAGO 281-611/281-418 is a gray 2-conductor fuse terminal block that uses CAGE CLAMP ® Spring crimping technology, compatible with 5 × 20mm cylindrical fuses, supports copper/aluminum conductor connections of 0.08-4mm ² (28-12AWG) (aluminum conductors need to be matched with Alu Plus contact paste), rated voltage of 800V, rated current of 10A, equipped with fuse indicator neon light (leakage current<0.4mA), can be installed on 35 × 15/7.5mm DIN rails, with a width of only 8mm, in compliance with IEC/EN 60947-7-3 standards, and has obtained multiple certifications such as CSA and UL. It is suitable for industrial and marine scenes, and comes with a variety of accessories such as end plates, rails, and wire noses.

Product basic information

Key parameters of the project

Product models 281-611/281-418

Product Type 2 Conductor Fuse Terminal Block

Appearance color: gray

Structural design corner type, single-layer level, center identification

Shell material: polyamide (PA66), UL94 V0 flame retardant rating

Physical dimensions: width 8mm, height 60mm, depth 60mm above DIN rail

Weight 17.5g

fire load 0.324 MJ

Packaging specifications: 50 pieces/box (PU/TPU)

Origin China (CN)

Customs code 85369095000

Core electrical and connection specifications

1. Electrical parameters

Rated voltage: 800V (IEC/EN 60947-7-3)

Rated current: 10A

Rated surge voltage: 8kV

Overvoltage category: Class III

Pollution level: Level 2 (regular)/Level 3 (specific scenario)

Power loss:

Overload+short circuit protection (separately arranged): 4W

Overload+short circuit protection (group arrangement): 1.6W

Short circuit protection (group arrangement): 4W

Fuse indication: neon light, leakage current<0.4mA when blown

2. Connection parameters

Connection technology: CAGE CLAMP ® Spring crimping technology

Operation method: Special operation tools are required

Conductor adaptation:

Copper conductor: 0.08-4mm ² (28-12AWG), solid/multi strand fine stranded wire

Aluminum conductor: 0.08-4mm ² (28-12AWG), requires WAGO Alu Plus contact paste (249-130)

Aluminum conductor current adaptation: 2.5mm ² corresponds to 16A, 4mm ² corresponds to 22A

Wiring requirements: Stripping length of 9-10mm, front wiring method

Anti corrosion properties: Contact paste can damage oxide film, prevent new oxidation and electrolytic corrosion

Installation and Accessories

1. Installation requirements

Installation method: DIN-35 rail installation (compatible with 35 × 15mm and 35 × 7.5mm rails)

Installation specifications:

When multiple terminal blocks are arranged adjacent to each other, end plates need to be installed at the ends

When installed vertically, the fuse holder can be securely locked in the open position

All positions have anti touch protection

Compatible rail types: aluminum, copper, steel (with/without grooves, length 2m)

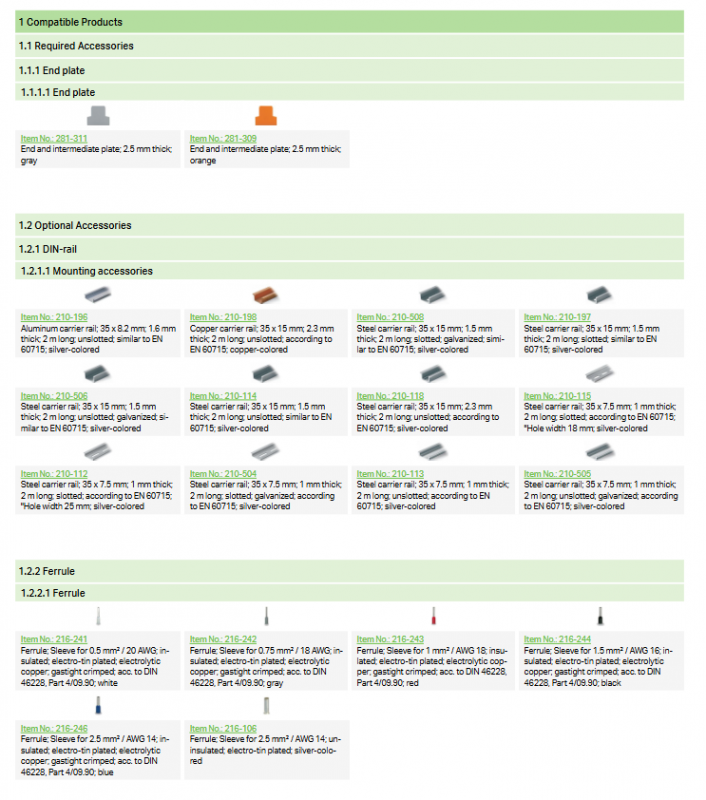

2. Supporting accessories

Accessory type, model, and description

Required accessories 281-311 (gray end plate), 281-309 (orange end plate)

Install guide rails 210-196 (aluminum 35 × 8.2mm), 210-114 (steel 35 × 15mm), etc

Threads 216-241 (0.5mm ²), 216-244 (1.5mm ²), 216-243 (2.5mm ²), etc

Jumping wires 281-402 (insulated gray), 709-110 (2.5mm ² black), etc

Identification accessories 793-5501 (retractable identification card), 2009-115 (printer specific identification roll)

Test accessories 249-147 (B-type test plug), 280-404 (test plug adapter)

Operating tools 210-658 (3.5 × 0.5mm insulated short handle tool), 210-657 (bent handle tool)

Certification and Compliance

1. General certification

Certification Body Standard Certificate Number

CSA Group C22.2 1505034

UL International UL 1059 E45172

KEMA/KEUR EN 60947 NTR NL-7135、2160584.31

2. Special certification

Ship certification: ABS (American Bureau of Shipping), DNV GL (Norwegian Classification Society)

Compliance standards: eCl@ss 9.0/10.0 (27-14-11-16), ETIM 8.0/9.0 (EC000899)

Declaration of Conformity: EU Declaration of Conformity, UK Declaration of Conformity

Usage and maintenance

1. Core functions

Fuse protection: compatible with 5 × 20mm cylindrical fuses, supporting overload and short circuit protection

Status indicator: Neon light visually displays whether the fuse is blown or not

Convenient testing: Supports voltage testing in both closed (energized) and open (unpowered) states, and can measure current

Splicing function: Multiple terminal blocks can be mechanically locked through interlocking links (210-254)

2. Steps for replacing fuses

Rotate the fuse holder to the locked open position (automatically locked when installed vertically)

When opening the lid, one end of the fuse will automatically pop out

Manually remove the blown fuse

Insert a new fuse, close the cover to complete the replacement