WAGO MCS Multi Connection System

WAGO MCS Multi Connection System is a CAGE CLAMP based system ® Or push in CAGE CLAMP ® The modular connector series of connection technology covers 7 product series including MICRO, MINI, MIDI, MAXI, etc. The pin spacing is 2.5-10.16mm, and it is compatible with 0.08-25mm ² (28-4 AWG) conductor specifications. It supports multiple connection methods such as wire to board, wire to wire, and board to board, and has 100% anti misoperation protection, custom coding, integrated buttons, and other features. The rated current is 6-76A and the rated voltage is up to 600V. It provides various versions such as THR reflow soldering and crimping installation, and is suitable for different application scenarios such as high-density connection and high current transmission of industrial equipment.

Product Overview

Key project information

Brand manufacturer WAGO Kontaketechnik GmbH&Co. KG

Core Technology CAGE CLAMP ® (Spring crimping) Push-in CAGE CLAMP ® (Push in spring crimping)

Connection type: wire to board, wire to wire, board to board, board to wire

Core advantages include 100% anti misconnection protection, custom coding options, support for solid/multi strand/thin stranded wires, and partially integrated button functions

Rated parameter current 6-76A, maximum voltage 600V (UL 1059)

Installation methods include Through Hole Reflow (THR reflow soldering), crimping installation, snap fit installation, and screw flange fixation

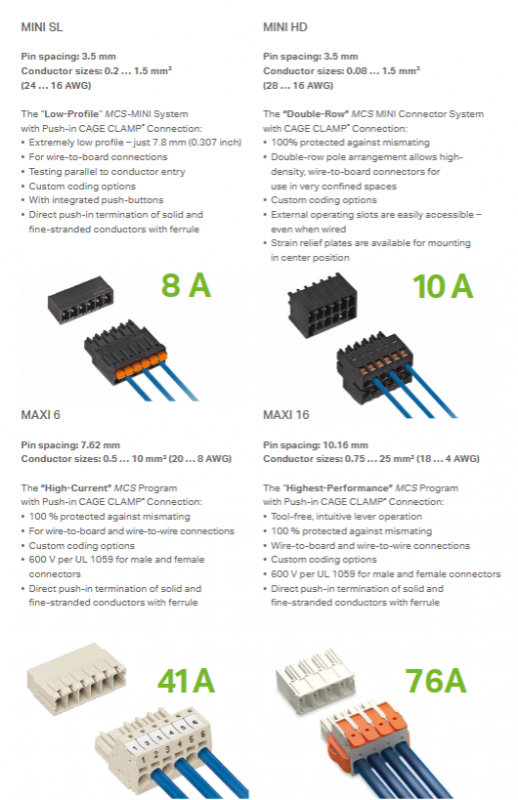

Core parameters of seven product series

Product series Pin spacing Conductor specifications Rated current Core characteristics Applicable scenarios

MICRO 2.5mm 0.08-0.5mm ² (28-20 AWG) 6A most compact design, THR version for high-density connection of micro devices

MINI 3.5mm, 3.81mm 0.08-1.5mm ² (28-14 AWG) 10A universal type, THR/crimping version, integrated button industrial equipment conventional connection

MINI HD 3.5mm (dual row) 0.08-1.5mm ² (28-16 AWG) 10A dual row layout, high-density space suitable for narrow spaces and high-density connections

MINI SL 3.5mm 0.2-1.5mm ² (24-16 AWG) 8A ultra-thin design (7.8mm), parallel testing of thin device connections

MIDI 5mm, 7.5mm 0.08-2.5mm ² (28-12 AWG) 10A multifunctional, long pin compatible rail terminal rail terminal connection expansion

MIDI Classic 5/5.08/7.5/7.62mm 0.08-2.5mm ² (28-12 AWG) 10A Classic, multi pin spacing optional, legacy device compatible

MAXI 6 7.62mm 0.5-10mm ² (20-8 AWG), high current, push in connection, power supply connection for medium power equipment

MAXI 16 10.16mm 0.75-25mm ² (18-4 AWG) 76A ultra-high current, lever operated high-power equipment for high current transmission

Key product characteristics

1. Advantages of Connection Technology

CAGE CLAMP ®: Tool operation is required to adapt to solid, multi strand, and fine stranded wires, ensuring reliable connection

Push-in CAGE CLAMP ®: Tool free push in type, compatible with solid/thin twisted wires with wire noses, efficient operation

Conductor compatibility: Supports copper conductors, some series are compatible with aluminum conductors (requires matching contact paste)

2. Highlights of functional design

Anti misconnection protection: 100% avoid mismatches, achieve multi circuit differentiation through custom coding

Integrated functions: Some models integrate buttons and locking levers to simplify equipment design

Convenient testing: MINI SL and other series support parallel testing during wiring, improving debugging efficiency

Flexible installation: provides right angle/straight insertion type, buckle/screw fixation, suitable for different installation spaces

3. Derivative versions and accessories

Welding version: THR reflow soldering is compatible with surface mount technology to improve production efficiency

Installation accessories: strain relief plate, identification component, end plate to enhance connection stability

Compatible accessories: Supports DIN-35 rail installation, compatible with WAGO rail terminal block

Compliance and adaptation standards

Voltage standard: MAXI series complies with UL 1059 600V standard

Conductor standard: compatible with AWG (28-4) and mm ² (0.08-25) dual specification conductors

Process adaptation: supports multiple processes such as reflow soldering, crimping, manual wiring, etc