REXROTH 4WRPEH series direct acting directional valve

The REXROTH 4WRPEH series direct acting directional valve is a high-performance control valve with electric position feedback and integrated electronic components (OBE). The specifications are Size 10, component series 3X, maximum working pressure 350 bar, rated flow 50~100 l/min, supports * * ± 10V/4-20mA/IO Link * * multiple control interfaces, and has the characteristics of safe failure position, low hysteresis (≤ 0.2%), energy-saving and no need for pilot oil. It is compatible with various hydraulic oils such as mineral oil and biodegradable oil, with a protection level of IP65, and can be used for position/speed/pressure control. The IO Link version can be used as an EN 13849-1 Cat3 PL d-level shut-off element, and the installation complies with ISO 4401-05-04-05. Standard.

Product Overview

Core positioning: The 4WRPEH series is a high-performance direct acting directional valve launched by Bosch Rexroth, designed specifically for industrial hydraulic systems. It achieves closed-loop control of valve core position through integrated electronic components (OBE), combining precision control with safety and reliability. It is suitable for scenarios that require control accuracy and safety.

Product Category

|Classification dimension | Specific type|

|Control interface | A1 (± 10V command/feedback), F1 (4-20mA command/feedback), C6 (± 10mA command/4-20mA feedback) L1(IO-Link) |

|Flow characteristics | L (linear), P (linear with inflection point, inflection point 40%)|

|Sealing material | M (NBR, compatible with mineral oil), no code (FKM, compatible with biodegradable oil/fire-resistant oil)|

|Special configuration | D (damping plate, suppresses>300Hz vibration), -967 (electronic protective film, anti condensation)|

Core strengths

Security guarantee: When the power is cut off, the valve core automatically resets to the safe failure position, and the IO Link version can meet the EN 13849-1 Cat3 PL d safety level.

Precise control: lag ≤ 0.2%, zero drift<1% (Δ θ=40 ℃), ensuring control accuracy.

Energy saving design: No need for pilot oil, reduces system energy loss, and is compatible with high-efficiency hydraulic systems.

Environmental adaptation: anti vibration (10g/2000Hz), anti impact (35g/6ms), protection level IP65, suitable for harsh industrial environments.

Intelligent interconnection: IO Link interface supports Industry 4.0, enabling remote parameter configuration and diagnosis.

Key technical parameters

(1) Summary of core parameters

Category specific indicators

Hydraulic parameters working pressure: P/A/B port 350 bar, T port 250 bar; Rated flow rate: 50/100 l/min (Δ p=35bar/control edge)

Oil requirements include mineral oil (HL/HLP), biodegradable oil (HETG/HEES), and fire-resistant oil (HFC/HFDU); Cleanliness ISO 18/16/13 level

Temperature range hydraulic oil: -20~+70 ℃; Environmental temperature: working -20~+60 ℃, transportation -30~+80 ℃

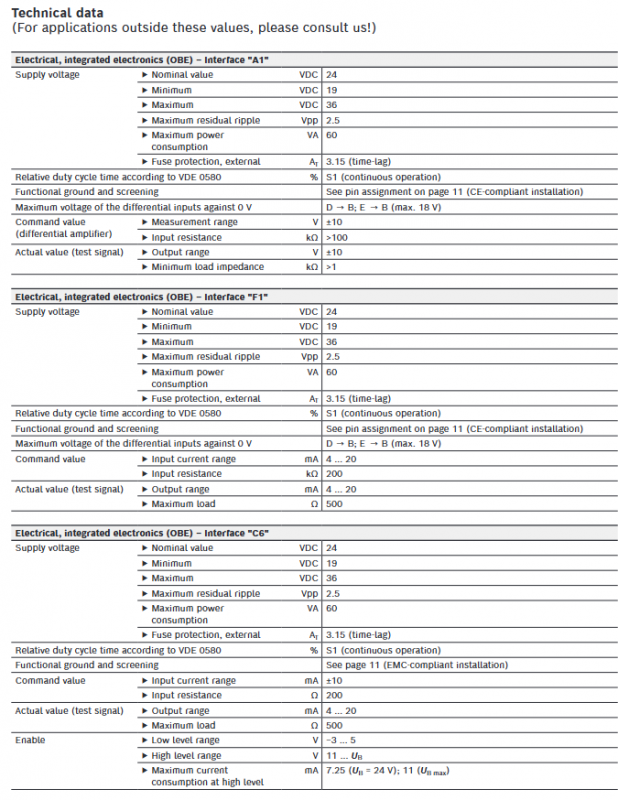

Electrical parameter power supply voltage: 24VDC (A1/F1/C6:19-36VDC; L1:18-30VDC); Power consumption: 60VA

Accuracy parameter lag ≤ 0.2%, zero calibration error ± 1% (factory preset), temperature drift<1% (Δ θ=40 ℃)

Mechanical characteristic weight 7.1kg; anti vibration: 10g (10-2000Hz); Impact resistance: 35g (6ms/1000 cycles)

(2) Interface parameter details

Interface type, command signal, feedback signal, cable length limit, core characteristics

A1 ± 10V (input resistance>100k Ω) ± 10V (load>1k Ω) up to 40m analog voltage interface, compatible with conventional controllers

F1 4-20mA (input resistance 200k Ω) 4-20mA (load ≤ 500 Ω) maximum 40m current loop interface, strong anti-interference ability

C6 ± 10mA (input resistance 200 Ω) 4-20mA (load ≤ 500 Ω) up to 40m dual current interface with enable signal

L1 IO Link (230.4kbit/s) intelligent interface with data exchange up to 20m, supporting parameter configuration and diagnosis

Principles of Structure and Function

Core structure: composed of valve body (including servo grade valve core/sleeve), control electromagnet with position sensor, integrated electronic components (OBE), reset spring, optional damping plate and electronic protective film.

Working principle: Integrated electronic components (OBE) compare command signals with actual position signals of the valve core, drive electromagnets to adjust valve core displacement, and achieve proportional control of flow/direction; When the power is cut off, the reset spring pushes the valve core to the safe failure position to ensure system safety.

safety function

Fault protection: When the power supply voltage is below the threshold (15V) and the command signal is abnormal (such as F1 interface<2mA), the electromagnet loses power and the valve core resets.

IO Link shutdown: Cut off the power supply (Class B port) through the IO Link master station, switch the valve core to the safe position, and meet the Cat3 PL d safety level.

Order Code Rules

Example of optional values for field position meaning

1-4 Product Series 4WRPEH (Direct Acting+OBE+Position Feedback)

Installation side (position sensor) B (designated installation side)

6-7 rated flow rate 50 (50l/min), 100 (100l/min)

8 Flow characteristics L (linear), P (linear with inflection point)

9-10 component series 3X (30~39 series, with unchanged installation dimensions)

11 Sealing Material M (NBR), No Code (FKM)

12 Special Configuration D (Damping Plate), No Code (No Damping Plate)

13 Power Supply Voltage 24 (24VDC)

14 Control interfaces A1, F1, C6, L1

15 electronic protective film-967 (available), no code (not available)

Installation and maintenance specifications

Installation requirements

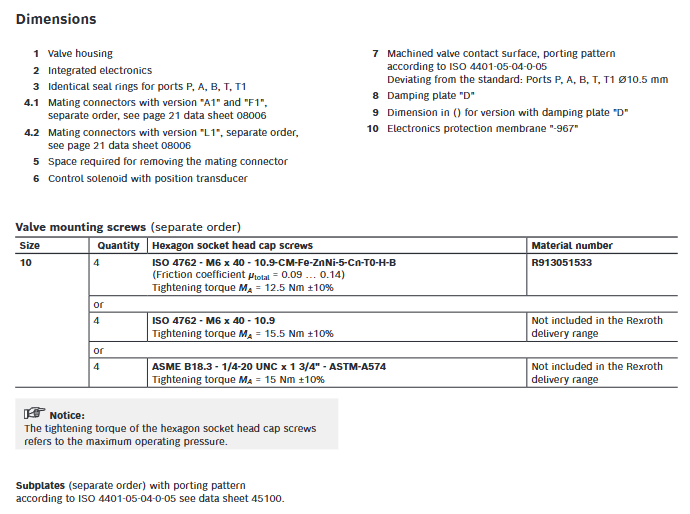

Installation surface: Surface roughness Rzmax 4, flatness 0.01/100mm, requires the use of specified M6 × 40 installation screws, tightening torque 12.5Nm (Rexroth original screws) or 15.5Nm (universal screws).

Cable connection: 6-core+PE cable (wire diameter 0.75~1.0mm ²), up to 40m; IO Link interface uses M12-5 core A code cable (up to 20m, wire diameter ≥ 0.34mm ²).

Wiring specifications: EMC compliant installation, metal connector grounding, cable shielding layer grounding at both ends (plastic connector only grounded on the power supply side).

Maintenance points

Oil maintenance: Maintain oil cleanliness at ISO 18/16/13 level, regularly replace filters to avoid impurities causing valve core jamming.

Electrical maintenance: It is prohibited to modify the factory preset potentiometer; Check the integrity of the cable sheath and replace it promptly if it is damaged.

Special maintenance: Electronic protective film (-967) is required for high humidity/temperature cycling environments; Optional damping plate (D) for vibration frequency>300Hz scenarios.