REXROTH EcoDrive Cs series AC servo drive system

Product Overview

Core positioning: EcoDrive Cs is a low-power AC servo drive system launched by Bosch Rexroth, consisting of DKC series drive controllers and MSM series permanent magnet synchronous servo motors, matched with dedicated cables, braking resistors and other accessories, forming a complete drive solution, targeting power requirements of 100-750 W, and achieving precise position and speed closed-loop control.

Product series division

|Category | Specific Model/Specification|

|Drive Controller | Divided by Interface: DKC01.3 (Analog/Parallel), DKC02.3 (SERCOS), DKC03.3 (PROFIBUS DP), etc; Divided by power: 004 (100W), 008 (200W), 012 (400W), 018 (750W)|

|Servo motor| MSM020B(100W)、MSM030B(200W)、MSM030C(400W)、MSM040B(750W), Each model comes with multiple configurations|

Core strengths

Bus compatibility: Supports various industrial buses such as PROFIBUS DP, CANopen, DeviceNet, SERCOS, etc., and is compatible with multiple brands of control systems.

Flexible configuration: The motor can be equipped with optional brake (0.29~2.45 Nm), incremental/absolute encoder, and optical/key shaft (DIN 6885 standard).

Safe and reliable: Complies with EN 50178 safety standards, with overvoltage, overload, and short circuit protection, leakage current>3.5 mA, requires dedicated PE wire grounding.

Easy installation: The controller supports 35mm standard rail installation, and the motor is compatible with various installation positions such as IM B5/V1/V3.

Easy maintenance: The motor bearings are maintenance free (with a lifespan of 30000 hours), the absolute value encoder battery can be replaced, and the fault diagnosis is intuitive (H1 display+S1 reset).

Key technical parameters

(1) Core parameters of drive controller (DKC series)

Specific indicators for parameter categories

Power range: 100 W (DKCxx. 3-004), 200 W (008), 400 W (012), 750 W (018)

Power supply specification sheet/three-phase AC 200~240 V (± 10%/-15%), frequency 50/60 Hz; control voltage 24 VDC

Continuous output current of 1.0~4.3 A, peak value of 3.0~12.9 A (400ms)

Control interface analog (± 10V/4-20mA), digital I/O (7-in, 3-out), encoder interface (incremental/absolute)

Protection level IP20 (installed inside the control cabinet)

Environmental conditions: working temperature of 0-40 ℃, storage temperature of -20~80 ℃, relative humidity ≤ 90% (no condensation), installation altitude ≤ 2000m (derating required)

Size, weight, weight 1.4~2.1 kg, length 70~170 mm (depending on model)

(2) Core parameters of servo motor (MSM series)

Model, Power, Continuous Torque, Peak Torque, Rated Speed, Maximum Speed, Moment of Inertia (kg · m ²), Weight (kg)

MSM020B 100W 0.3 Nm 0.95 Nm 3000 min ⁻¹ 5000 min ⁻¹ 0.032 × 10 ⁻⁴ 0.5 (0.7 with brake)

MSM030B 200W 0.64 Nm 1.91 Nm 3000 min ⁻¹ 5000 min ⁻¹ 0.1 × 10 ⁻⁴ 0.96 (1.36 with brake)

MSM030C 400W 1.2 Nm 3.8 Nm 3000 min ⁻¹ 5000 min ⁻¹ 0.17 × 10 ⁻⁴ 1.5 (1.9 with brake)

MSM040B 750W 2.4 Nm 7.1 Nm 3000 min ⁻¹ 4500 min ⁻¹ 0.67 × 10 ⁻⁴ 3.1 (3.8 with brake)

Common parameters —

Protection level – IP65 (enclosure), IP40 (output shaft)

Insulation level – Class B (up to 130 ℃)

Encoder – Incremental (10000 resolution), Absolute Value (17 bit single loop+16 bit multi loop)

Core configuration and selection

Controller classification and interface

Basic type (DKC10.3): No bus module, supports digital I/O control (7-in, 3-out).

Bus type (DKC03.3/05.3/06.3): Supports PROFIBUS DP, CANopen, and DeviceNet respectively, and requires ECM series main communication cards.

SERCOS type (DKC02.3): Fiber optic interface, switchable transmission power, maximum transmission 500m (glass fiber).

Analog/Parallel (DKC01.3): Supports ± 10V/4-20mA instructions, encoder simulation output.

Optional motor configuration

Encoder: incremental (relative position, no battery required), absolute value (absolute position, requiring 3.6V lithium battery backup).

Axis type: optical axis (friction locking connection), with key axis (DIN 6885 standard, key specifications 3 × 3 × 16~6 × 4 × 25).

Brake: 24VDC electric release type, brake torque 0.29~2.45 Nm, used for vertical axis anti fall (additional mechanical protection required).

List of Key Accessories

|Accessory type | Model example | Purpose|

|Motor cable | IKG0331 | Controller and motor power connection, up to 40m in length|

|Encoder cable | IKS0230 | Encoder signal transmission, dual shielding design|

|Braking resistor | EBR01-0100-100R-V-D | Absorbs regenerative energy, avoids overvoltage, 100 Ω/100W|

|NTC Thermistor | SUP-E05-DCCS-SURGEP | Reduces startup surge current, 33 Ω (25 ℃)|

|Encoder Adapter | SUP-E04-DKCCS-ENCODR | 1Vess Encoder Adaptation Controller|

|Debugging cable | IKB0041 | PC and controller RS232 communication debugging|

Installation and wiring specifications

Controller installation requirements

Installation method: 35mm standard top cap guide rail (TH 35-7.5/15), vertically installed (utilizing natural convection heat dissipation).

Space requirement: Reserve a heat dissipation gap of ≥ 40mm around the perimeter to avoid close placement with power electronic components such as frequency converters (spacing ≥ 10cm).

Fixed torque: The installation screw torque is matched according to the model (such as using M4 screws for DKC02.3, with a torque of 3.1 Nm).

Core wiring specifications

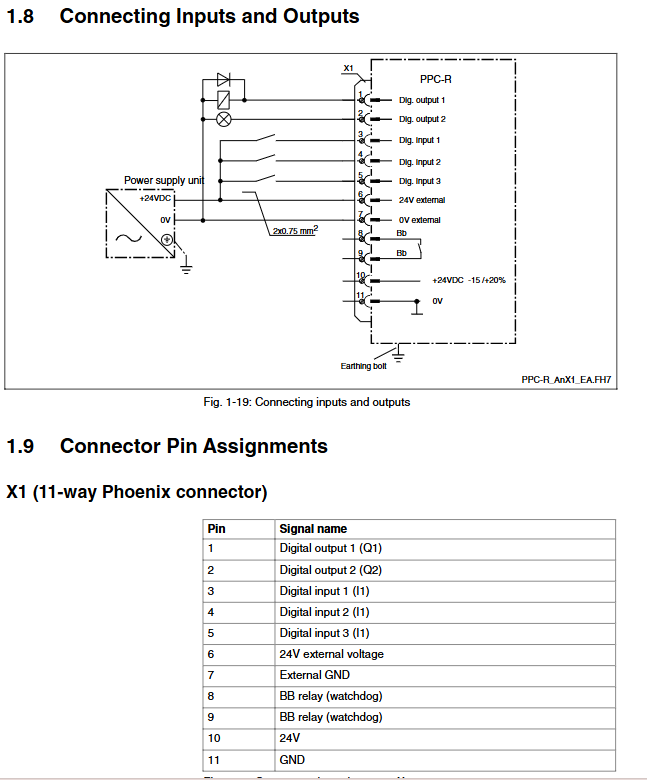

Power wiring: Single/three-phase power supply needs to match the voltage range, with a PE wire cross-section of ≥ 10 mm ² and a grounding resistance of ≤ 4 Ω; The control voltage of 24VDC requires separate wiring, with ripple ≤ 1.5Vpp.

Cable selection: The cross-section of the power cable should be ≥ 0.75 mm ², and the encoder cable should be double shielded with a distance of ≥ 100mm from the power cable. The maximum length of the motor cable is 40m, and the maximum length of the encoder cable is 40m.

Bus wiring: A 121 Ω terminal resistor is required to be connected at both ends of the PROFIBUS DP bus. The CANopen bus supports addresses 1-127, and the SERCOS fiber optic switch needs to be set according to the transmission power.

EMC compliance requirements

Cable shielding: single end grounding of power cable shielding layer, double end grounding of signal cable; The shielding layer of the motor cable is grounded through a connector.

Filter configuration: A dedicated power filter (such as NFE01.1) needs to be installed to suppress electromagnetic interference and comply with EN 55022 Class A standard.

Debugging and maintenance

Debugging process

Hardware connection: Connect the PC to the X6 interface of the controller using an RS232 cable (IKB0041), and check the wiring before powering on (discharge after 5 minutes of power-off).

Software configuration: Install DriveTop software (Windows system), set communication parameters (default baud rate 9600bps), load motor parameters, control mode, and bus address.

Trial operation: First, test the speed/steering without load (up to 5000 min ⁻¹), then verify the position accuracy with load (error ≤± 2 arcminutes), and confirm that the emergency stop function is effective.

routine maintenance

Motor maintenance: Maintain IP65 protection integrity to avoid oil intrusion; Activate the brake every 48 hours to prevent rusting and avoid sticking.

Encoder maintenance: The battery life of the absolute value encoder is about 10 years, and it needs to be replaced when the equipment is loaded and the control voltage is turned on to avoid absolute position loss.

Controller maintenance: Check the wiring tightness annually and clean the dust on the heat sink; Avoid overload operation (continuous current not exceeding rated value).

Fault handling

Diagnosis display: The H1 indicator light displays an error code (such as F248=low battery voltage), and the S1 button can reset non fatal errors.

Common faults: overvoltage (check brake resistor connection), overload (reduce load or prolong acceleration time), communication fault (check bus parameters and cables), encoder fault (check cables or batteries).

Application scenarios and limitations

Applicable scenarios

Industrial equipment: handling and assembly systems, packaging and food machinery, printing machines, small machine tools.

Control requirements: Low power loads that require precise position/speed control, single axis or multi axis synchronous applications (such as assembly line conveying, robotic arm positioning).

Usage restrictions

Prohibited for use in personnel transportation equipment, medical equipment, explosion-proof environments (non explosion-proof models), nuclear industry, mining and other scenarios.

If it exceeds the ambient temperature (0-40 ℃) or altitude (>1000m), it needs to be downgraded for use (2% for every 1 ℃ and 10% for every 1000m).

If the power supply voltage exceeds the range of 200~240V, an autotransformer (such as DST series) should be configured, and direct connection to 400V mains is prohibited.