REXROTH MKD series explosion-proof synchronous motor

The REXROTH MKD series explosion-proof synchronous motor is a Class II, Zone 3 (gas/dust environment) explosion-proof motor that complies with ATEX standards. The models include MKD025, MKD041, MKD071, MKD090, with a continuous torque of 0.4-12 Nm, a maximum speed of 5000-9000 min ⁻¹, a protection level of IP65, an insulation level of F, and comes standard with a rotary transformer encoder. Multiple absolute value encoders and brake configurations can be selected, and specialized controllers such as DIAX04 and ECODRIVE are suitable for industrial scenarios such as machine tools, printing, and packaging. Installation, operation, and maintenance must strictly follow explosion-proof and safety regulations.

Product Overview

Product positioning: The Bosch Rexroth MKD series is a synchronous servo motor designed specifically for potentially explosive environments, complying with the ATEX directive 94/9/EG, classified as Class II, Zone 3 (GD), with a protection type of EEx nA (non spark type), a maximum surface temperature of 155 ° C, and suitable for industrial scenarios where gas or dust occasionally occurs.

Core strengths

Explosion proof safety: meets the EN 50021 standard, avoiding sparks or high temperatures that may cause explosions during operation.

Flexible configuration: supports multiple optional configurations such as encoder type, brake, output shaft form, etc.

Wide adaptability: compatible with Rexroth dedicated controllers, covering low, medium, and high power requirements.

Stable and reliable: The rated life of the bearing is 30000 hours, and its anti vibration and anti impact performance meets the DIN EN 60068 standard.

Applicable scenarios: Machine tools, printing and paper processing equipment, packaging and food processing equipment, automation and handling systems, etc. It is prohibited to use them in coal mines, personnel transportation equipment, medical equipment and other scenarios.

Core technical parameters

(1) Summary of Key Performance Parameters

Model: Machine Base Length, Continuous Torque (60K), Maximum Speed, Motor Weight, Brake Torque

MKD025A A 0.4 Nm 9000 min⁻¹ 1.5 kg –

MKD025B B 0.9 Nm 9000 min⁻¹ 2.0 kg 1.0 Nm

MKD041B B 2.7 Nm 7500 min⁻¹ 4.4 kg 2.2 Nm

MKD071B B 8.0 Nm 6000 min⁻¹ 8.8 kg 5.0/10 Nm

MKD090B B 12.0 Nm 5000 min⁻¹ 14.0 kg 11.0 Nm

(2) Classification parameter details

Electrical parameters: rated power supply 24VDC (± 10%), continuous current 2.2~17.2A, peak current 10.0~79.0A; torque constant 0.2~2.01 Nm/A, voltage constant 18.2~174.9 V/1000min ⁻¹.

Mechanical parameters: moment of inertia 0.2 × 10 ⁻⁴~43.0 × 10 ⁻⁴ kgm ²; Allow the radial load to vary with the model (e.g. MKD025 maximum 500N), and the axial load to be 0.34-0.59 times the radial load.

Environmental and explosion-proof parameters: storage temperature -20~+80 ° C, working environment temperature 0~40 ° C; altitude up to 1000m; suitable for gas (G) and dust (D) explosion-proof environments, temperature group T155 ° C.

Structure and optional configurations

Core structure

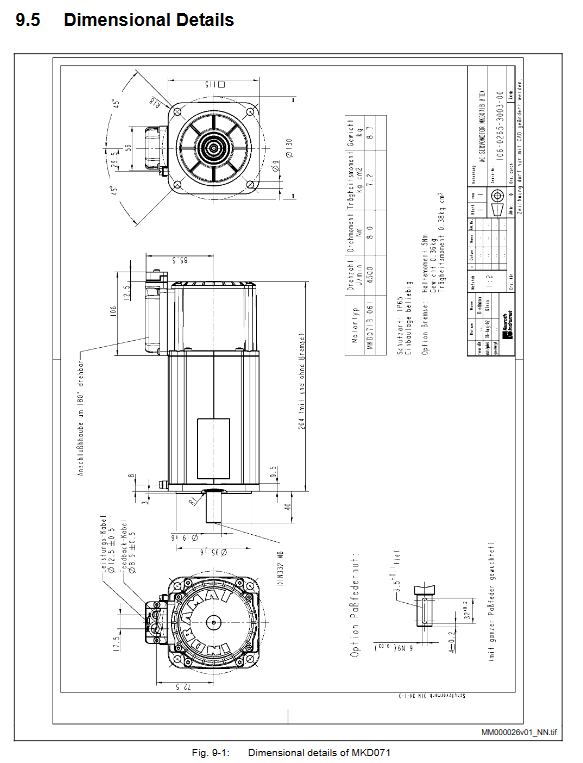

Motor body: The base adopts RAL 9005 black coating, B5 installation form (flange installation), and the output shaft complies with DIN 748 standard.

Encoder: standard rotary transformer (relative type, accuracy ± 8 arcminutes), optional multi turn absolute encoder (4096 turns, battery backup, lifespan of about 10 years).

Brake (optional): 24VDC electric release type, power-off clamping, connection time 3-26ms, disconnection time 4-43ms, suitable for vertical axis anti fall requirements.

Optional configuration

Output shaft: Optical axis (with central threaded hole), keyway shaft (compliant with DIN 6885).

Accessories: GTS/GTP/GTM series planetary gearbox (IP65 protection, lifetime lubrication), dedicated power/encoder cable, connectors (6-pin+PE, 4-pin).

Selection rules (ordering code)

The ordering code consists of 10 core codes, and the key fields are described as follows:

Example of optional values for the meaning of encoding fields

1-3 Product Series MKD

4-6 aircraft seat number 025/041/071/090

7 machine base length A/B (length B has higher torque)

8-10 winding codes 024/035/058/061, etc

13 Encoder Type G (Rotary Transformer)/K (Absolute Value)

14 output shaft form G (optical axis)/P (with keyway)

15 brake 0 (none)/1/2/3 (different torque)

18 Explosion proof Type S (Class II, Zone 3 Explosion proof)

Installation and operation specifications

Installation requirements

Installation form: Only supports B5 flange installation (IM B5/V1/V3 posture), vertical installation (IM V3) needs to prevent liquid intrusion.

Transportation and storage: must be placed horizontally to avoid impact; The storage environment should be dry and dust-free, and the shaft end protective cover should be retained.

Fixed torque: Different models correspond to different installation screw torques (such as MKD025 using M4 screws with a torque of 3.1 Nm).

Wiring and Grounding

Cable requirements: Special cables with a temperature resistance of ≥ 80 ° C and a cross-section of ≥ 1.0mm ² must be used; Separate the wiring of power cables and encoder cables.

Grounding specification: The motor requires dual grounding – cable internal grounding wire+flange separate grounding wire (section ≥ 4mm ²), in accordance with EN 50021 standard.

Taboo: Do not plug or unplug connectors with electricity in explosive environments; Prohibit the use of non explosion proof accessories (such as ordinary blowers).

safe operation

Pre start inspection: manually rotate the rotor without any jamming, the brake function is normal, and the wiring is tight.

Emergency stop: An independent emergency stop circuit is required to cut off the motor power supply for rapid braking.

Maintenance taboos: It is prohibited to disassemble explosion-proof related components, modify windings or sealing structures.

Maintenance and troubleshooting

routine maintenance

Cleaning: Regularly clean the dust on the heat sink to avoid affecting heat dissipation.

Brake maintenance: Activate the brake every 48 hours (100 minutes ⁻¹ speed, 1 turn) to prevent rust film from forming; Before first use, it needs to be run in (5 laps).

Cable inspection: Regularly check the integrity of the cable sheath, and replace it immediately if it is damaged.

Battery replacement: The absolute value encoder battery needs to be replaced when the device is loaded and the control voltage is turned on to avoid absolute position loss; The replacement component model needs to be matched (such as MKD025 corresponding to part number 296044).

Common taboos

Overloading operation is prohibited: otherwise, it will cause the motor temperature to exceed the standard and damage the explosion-proof performance.

Prohibited from arbitrary adjustment: Zero calibration, torque parameters, etc. must be operated by professional personnel, and factory presets cannot be modified without authorization.

Prohibition of mixing controllers: Only compatible with dedicated controllers such as Rexroth DIAX04 and ECODRIVE are allowed.