Kollmorgen SERVOSTAR 600 (S600) series digital servo drive

Product Overview and Model Code

Product Core Positioning

The S600 series is a digital servo drive launched by Kollmorgen for medium to high power and high-precision motion control scenarios. The hardware version has been iterated to 05.40 and supports multiple types of feedback devices and bus expansion. It can also be equipped with an optional AS restart lock safety function, and is compatible with synchronous servo motors, linear motors, and asynchronous motors. It can expand I/O and communication capabilities through expansion cards. Its core advantages lie in medium to high power coverage, high control accuracy, and flexible expansion. It is widely used in automation production lines, multi axis collaborative equipment, precision machine tools, and other scenarios.

Model coding rules

The model consists of “series+current level+voltage type+function options+expansion card”, and the core coding dimensions and example analysis are as follows:

Explanation of the meaning of the coding section and key codes

Series Identification Core Product Series S601 (1.5ARMS), S603 (3ARMS), S610 (10ARMS), S620 (20ARMS)

Current level Continuous current specifications 01 (1.5ARMS), 03 (3ARMS), 10 (10ARMS), 20 (20ARMS)

Voltage type power supply input type 0 (3 × 208-480VAC)

Function Options Core Function Configuration – NA (No Extension), – AS (Restart Lock Function)

Expansion card optional expansion modules OPT-EI (I/O-14/08), OPT-PB (PROFIBUS), OPT-EC (EtherCAT)

Core Technical Parameters

Power Supply and Current Parameters

Model Supply Voltage Continuous Current (ARMS) Peak Current (ARMS) Maximum DC Bus Voltage (VDC) Heat Loss (W)

S601 3×208-480VAC 1.5 3 675 15

S603 3×208-480VAC 3 6 675 30

S606 3×208-480VAC 6 12 675 60

S610 3×208-480VAC 10 20 675 90

S614 3×208-480VAC 14 28 675 120

S620 3×208-480VAC 20 40(2s) 675 150

Control Performance and Safety Parameters

Dynamic performance: Switching frequency of 8kHz (optional 16kHz below 400V), current loop bandwidth>1.2kHz, speed loop update cycle of 65 μ s/250 μ s, position loop update cycle of 250 μ s

Feedback resolution: Sin Cos encoder supports 1Vpp signal, EnDat2.1/HIPERFACE supports high-resolution absolute feedback

Security function: – AS restart lock function complies with EN954-1, supports security category 1/3, response time ≤ 1ms

Braking circuit: Built in braking resistor (66 Ω for 601/603, 33 Ω for 606-620), supports external braking resistor expansion, braking threshold 400-870VDC

Installation and wiring specifications

Installation Requirements

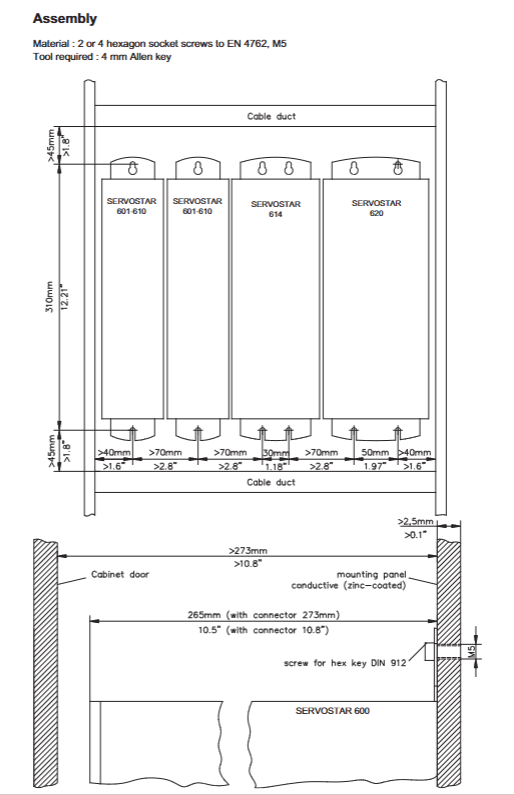

Installation method: Vertically installed on a conductive grounding surface, the control cabinet requires forced ventilation

Cooling gap: top/bottom ≥ 45mm, side ≥ 70mm, high-power models (S614/S620) require the installation of a fan

Mechanical dimensions: Width 70-120mm (70mm for 1.5-10ARMS, 100mm for 14ARMS, 120mm for 20ARMS), height 275mm, depth 265mm, weight 4-7.5kg

Environmental restrictions: Working temperature 0-45 ℃ (with a capacity reduction of 2.5%/℃ for 45-55 ℃), humidity 10-85% (without condensation), altitude<1000m (with a capacity reduction of 1.5%/100m for 1000-2500m)

Core interface wiring

The manual provides detailed wiring definitions for 15 core interfaces, with the following key points:

Power wiring: X0A/X0B interface connected to 3-phase main power supply, L1/L2/L3 phase connected, PE grounding in accordance with IEC 60364 specification

DC bus wiring: The X7 interface supports parallel connection of multiple drivers (total current ≤ 40A), requiring the use of 2.5mm ² shielded cables with a length ≤ 200mm

Motor wiring: X9 interface connects U/V/W three-phase, brake signal BRAKE+/BRAKE – supports 24VDC/2A brake control, motor cable>25m requires motor choke coil 3YL

Feedback wiring: X1 supports Sin Cos/BiSS/EnDet, X2 supports Resolvers, X5 supports SSI/incremental encoders, feedback cables require twisted pair shielding

-AS functional wiring: The X10 interface is connected to a 24V control signal and must be wired according to EN954-1 specifications to ensure activation after mechanical load locking

Parameter Configuration and Control Mode

Basic Configuration

Station address and baud rate: Set through the front panel buttons, CANopen defaults to a baud rate of 500kBaud and supports 10-1000kBaud adjustable

-AS configuration: An external safety relay (compliant with EN954-1) is required, and wiring should be kept away from power cables. Before activation, ensure that the motor is stopped (speed ≤ 5rpm)

Braking threshold: Set through DRIVE. EXE software, default 400VDC (230VAC model), 720VDC (400VAC model), 840VDC (480VAC model)

Core parameter configuration

Parameter Category Key Parameter Function Description Value Range

Current loop Kp proportional gain 0.1-100 V/A

Speed loop Kp Speed loop proportional gain 0.1-100 ARMS/rad/s

Speed loop Ki Speed loop Integral gain 0-1000 Hz

Position loop Kpp Position loop proportional gain 0.1-100 Hz

Electronic Gear GearIn/GearOut Electronic Gear Ratio 1-65535

Current limit I RMS/I Peak Continuous/Peak current limit 0-100% rated value

Feedback configuration FBTYPE feedback type selection 0 (Resolver), 20 (BiSS), etc

Control mode configuration

Torque mode: Supports ± 10V analog commands, with a resolution of 14 bits, suitable for torque closed-loop control scenarios

Speed mode: Supports analog commands, pulse commands, or bus commands, with a stable speed accuracy of ± 0.1% and a maximum speed of 6000rpm

Position mode: Supports step direction (1.5MHz), electronic gear, multi axis master-slave cooperation, and position error window can be set

Electronic gear: supports external encoder as the main shaft, follows proportionally from the shaft, with a gear ratio accuracy of 1/65535

Troubleshooting and Maintenance

Core fault codes and troubleshooting

Fault codes, fault types, common causes, troubleshooting methods

F01 heat sink overheating environment temperature is too high, and the heat dissipation gap is insufficient. Clean the heat dissipation channel, reduce the load, and check the fan

F02 bus overvoltage brake resistor failure, rapid deceleration check brake resistor wiring, extend deceleration time, install external brake resistor

F04 feedback fault feedback cable breakage, wiring error check feedback wiring, measure feedback power supply, replace cable

F06 motor overheating, motor overload, thermal sensor failure to reduce load, check motor thermal sensor wiring, measure winding temperature

F27-AS function failure – AS enables effective adjustment of control logic simultaneously with ENABLE to ensure that the motor has stopped before AS activation

Key points of daily maintenance

Regular inspection: cleaning of heat dissipation channels, fastening of wiring terminals, integrity of feedback cable shielding, recommended every 6 months

Capacitor reformation: When stored for more than 1 year without use, 230VAC single-phase electricity needs to be added for 30 minutes to activate the capacitor

Parameter backup: Backup parameters (. cfg files) through DRIVE. EXE software to avoid configuration loss due to misoperation

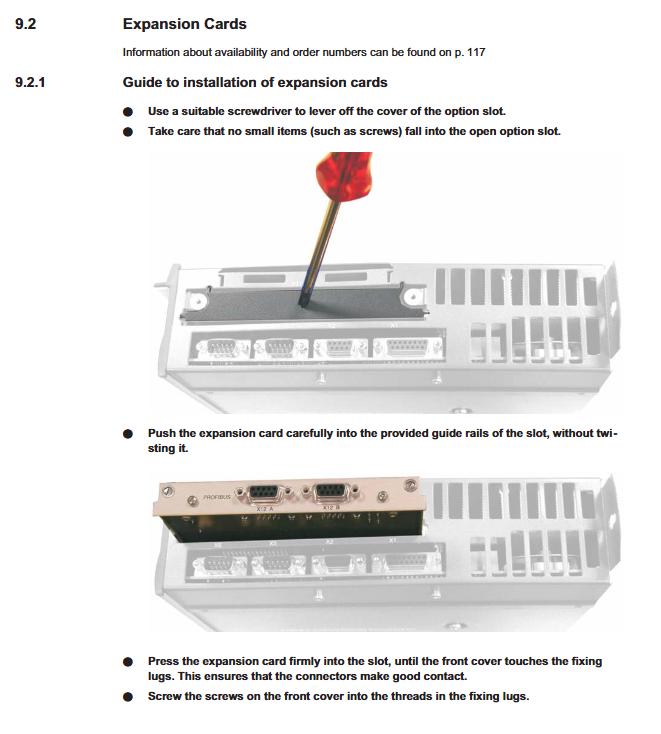

Expansion card maintenance: When inserting or removing expansion cards, power must be turned off. During installation, ensure that the guide rail is inserted into place and the screws are tightened

Expansion Cards and Accessories

Core Expansion Card

Expansion card type, model, core function, interface type

I/O Expansion OPT-EI 14 channel digital input, 8 channel digital output MiniCombicon

PROFIBUS OPT-PB supports PROFIBUS DP protocol SubD 9-pin

EtherCAT OPT-EC supports EtherCAT bus and RJ45 ring network topology

SynqNet OPT-SN supports SynqNet network and multi axis synchronous RJ45

Dual CAN OPT-2CAN separates RS232 and CAN interfaces, supports bus terminal SubD 9-pin x 3

DeviceNet OPT-DN supports the DeviceNet protocol and has adjustable node addresses for MiniCombicon

Special Accessories

Braking resistor: Supports 200-1500W external braking resistor, recommended resistance value of 33 Ω (universal across the entire series)

Cable: Dedicated motor/feedback cable, supports single cable connection, protection level IP67

Connector: X0/X7/X9 dedicated connector, suitable for current carrying requirements of different voltage levels

Software tool: DRIVE. EXE (Windows compatible), supports parameter configuration, oscilloscope monitoring, and fault diagnosis