Honeywell Fusion4 MSC-L Multi Stream Loading Controller

Product basic positioning and adaptation scenarios

Core positioning: A pre-set loading controller designed specifically for industrial terminal automation, with the core goal of improving loading throughput, shortening operation time, reducing measurement errors, lowering compliance costs, and ensuring safe, reliable, and accurate trade handover of media such as petroleum products.

Adaptation scenarios:

Road transportation: loading/unloading of tank trucks, loading of LPG/LNG tank trucks

Railway transportation: loading of railway tank trucks

Air transportation: aviation refueling

Storage and pipeline: storage transfer, ship refueling, pipeline transportation, transportation refueling

Core advantages: intuitive operation (icon driven interface), flexible deployment (modular design), convenient integration (multi protocol support), safety compliance (global explosion-proof certification), efficient maintenance (diagnostic dashboard+on-site upgrade).

Core functions and features

1. Loading control and mixing capability

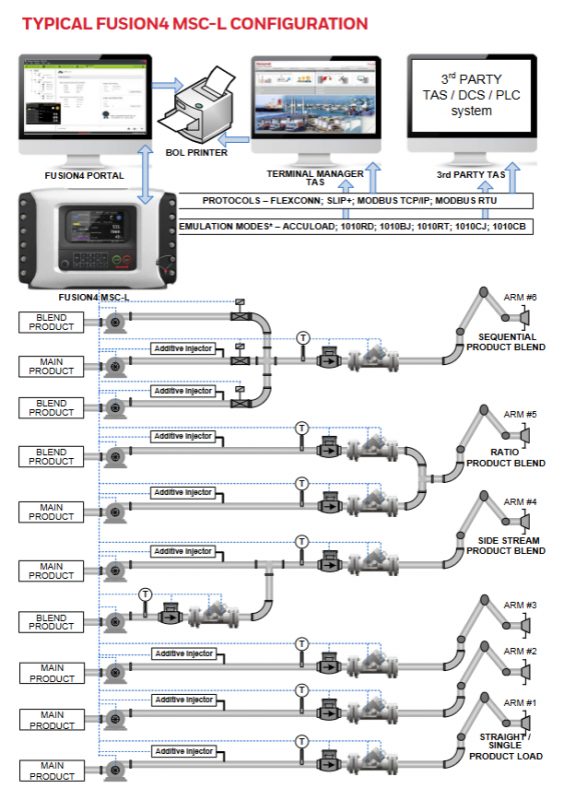

Control mode: Supports four core modes: Straight, Ratio, Side Stream, and Sequential. It also supports internal/external additive injection control

Control algorithm: Adopting proportional integral feedforward (PI-FF) control algorithm, dynamically setting control points, optimizing valve control based on preset flow curve, reducing valve wear, improving control accuracy and repeatability

Interrupt recovery: Automatically recalculate the mixing accuracy after loading the interrupt to ensure that the delivered medium meets the specification requirements

Valve adaptation: compatible with digital valves, analog valves, and two-stage control valves, supporting precise parameter tuning

2. Operation and display experience

Display configuration: 8-inch WVGA full-color TFT display screen, 16:9 aspect ratio, adjustable backlight, supports clear display under strong light

Operating interface: Icon driven design, intuitive and easy to understand, significantly reducing training costs; Real time dynamic display of loading status, flow curve, and progress bar for quick monitoring

Language support: Covering 15+languages, including English (US/UK), Chinese (Simplified), Japanese, French, Spanish, German, etc

Quick start: boot time ≤ 1 minute, supports configuration file import, accelerates multi device deployment

3. Safety and compliance features

Explosion proof certification: Global mainstream explosion-proof certification covers all aspects, including ATEX(II 2 G Ex db [ia] IIB T6 Gb)、IECEx(Ex db [ia] IIB T6 Gb)、FM/CSA(Class1 Div1 Group C&D T6)、CCOE wait

Protection level: IP66 (dustproof and waterproof)/NEMA 4X, suitable for harsh industrial environments

Security control:

Multi level password protection, supporting local/remote authorization

Driver/vehicle ID management (up to 1000 each), automatic locking for illegal access

Programmable alarm function, supports custom alarm conditions and prompt information, can configure alarm actions such as “display only”, “display+stop”, “display+pause”, etc

Deadman function is optional to enhance job safety

4. Data storage and traceability

Log capacity: Supports 10000 transaction logs, 2000 audit trail logs, and records the entire loading process data

Formula storage: Up to 300 mixed/additive formulas can be stored, with a single formula supporting 1 main stream, 3 mixed streams, and 6 additive streams. A single loading arm can hold up to 50 formulas

Traceability tool: Fusion4 Portal software can export logs, generate audit reports, and support trade handover compliance traceability

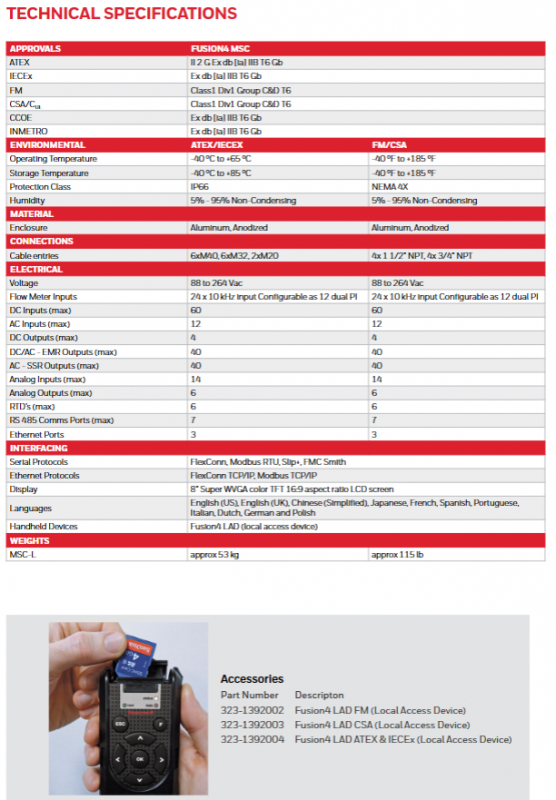

Hardware configuration and specifications

1. Model series and loading arm configuration

Model Series Loading Arm Quantity Core Features Dual Cabin/Swing Support

MSC-L1/L2/L3 1/2/3 standard single cabin configurations are not supported

MSC-L1D/L2D/L3D 1/2/3 standard configurations support dual cabin/swing

MSC-XL1~XL6 1~6 expansion configurations, dual backplane design XL1~XL4 supports dual cabin/swing

2. Power supply and I/O specifications

Power supply requirements: 88-264VAC wide voltage input, compatible with global power grids

Core I/O capacity (maximum configuration):

|I/O type | specification parameters|

|Pulse input | 24 channels of 10kHz, configurable as 12 channels of dual pulse input|

|DC input | 60 channels|

|AC input | 12 channels|

|DC output | 4 channels|

|EMR/SSR output | 40 channels each|

|Analog Input (AI) | 14 Channels|

|Analog output (AO) | 6 channels|

|RTD input | 6 channels (temperature measurement)|

3. Communication interface

Ethernet: up to 3 ports, supports IEEE 802.3 10/100 Base-T, protocols include Modbus TCP/IP, FlexConn TCP/IP

Serial ports: up to 7 RS485 ports, supporting 2-wire/4-wire mode, protocols include Modbus RTU, SLIP+, FlexConn (proprietary) FMC Smith

Other interfaces: Supports external device docking such as NexWatch DR4208 card reader, NEDAP RFID, Mettler Toledo weighing scale, etc

4. Physical and environmental parameters

Category parameter specifications

Aluminum anodized shell material

Protection level IP66 (Metric)/NEMA 4X (NPT)

Working temperature -40 ℃~+65 ℃

Storage temperature -40 ℃~+85 ℃

Relative humidity 5%~95% (no condensation)

Weight approximately 53kg (115lb)

Cable interface Metric: 6 × M40, 6 × M32, 2 × M20; NPT: 4 × 1.5 “, 4 × 0.75”

Software and supporting tools

Fusion4 Portal software

Core functions: remote monitoring of loading status, remote configuration of device parameters, batch import/export of configuration files, generation and printing of trade handover documents (BOL), viewing alarm records and communication status

Integration capability: Supports seamless integration with Honeywell Terminal Automation System (TAS) and third-party TAS

2. Fusion4 LAD (Local Access Device)

Application scenario: Local operation in hazardous areas without opening the device casing

Core functions: parameter adjustment, alarm reset, firmware upgrade, configuration file upload/download, support for quick startup

3. Simulation and configuration functions

Simulation mode: Supports various mainstream simulation modes such as Accuroad, 1010BJ, 1010RT, 1010CJ, 1010CB, etc., for easy system replacement and upgrade

Flexible configuration: customizable I/O function allocation, programmable batch workflow settings, support for free-form user-defined prompt items (such as user ID, vehicle ID, contract number, etc., can be set as disabled/optional/required)

Key configuration parameters

1. System basic configuration

Default values for optional range of configuration items

Preset units of GOV (apparent volume), GSV (standard volume), Mass (mass) GOV

Temperature units Celsius (℃), Fahrenheit (℉) Celsius

Pressure units: pascal (Pa), kilopascal (kPa), pound per square inch (PSI), bar pascal

Density unit in kilograms per cubic meter (kg/m ³), API degree, pounds per cubic foot (lb/ft ³), relative density at 60 ℉, kilograms per liter (kg/L), kilograms per cubic meter

Authorization mode includes no verification, local verification, remote verification, and local verification

Authorization type none, PIN code, NexWatch, Nedap PIN code

Baud rate 1200~128000Bd 9600Bd

2. Loading arm configuration

Each loading arm can independently configure the loading type (top loading/bottom loading), mixing mode, and recipe association

Supports Dual Bay and Swing functions (only supported on MSC-LxD/XL1~XL4 models)

Pulse allocation: Pulse signals for products and additives can be allocated based on on-site conditions