BENDER RCMA475LY AC/DC sensitive residual current monitor

Product Overview

RCMA475LY is an industrial grade AC/DC sensitive residual current monitor launched by BENDER in Germany, designed specifically for TN and TT systems (grounded power supply systems). Its core function is to monitor AC, DC, and pulsating DC currents in circuits, accurately identify DC fault currents or residual currents that are continuously greater than zero, and prevent safety risks such as electrical fires and electric shocks. Its unique Type B working characteristics make it particularly suitable for scenarios containing six pulse rectifiers, unidirectional rectification filtering loads, such as frequency converters, battery chargers, construction site variable frequency drive equipment, uninterruptible power supplies (UPS), etc. It is a key equipment for high reliability electrical safety monitoring in industrial production and civil buildings.

Core certification: Compliant with IEC/TR 60755 Type B standard, with EN 61543 and EN 61000-6-4 electromagnetic compatibility (EMC) certification, flame retardant rating of UL94V-0 for the shell, and protection level of IP30.

Core functions and features

(1) Monitoring and threshold control function

Dual level response threshold:

Alarm threshold (I Δ n1): 30… 500mA continuously adjustable, covering various monitoring requirements from low sensitivity to high sensitivity, with a frequency range of 0… 700Hz, suitable for the current characteristics of high-frequency rectifier loads.

Warning threshold (I Δ n2): Supports switching between two modes (set through DIP switch), with the option to select 50% or 100% of the alarm threshold, achieving a graded protection of “early warning+emergency alarm”, making it easy for users to distinguish risk levels and handle them in a timely manner.

Adjustable response delay:

Alarm delay: 0… 10s infinitely adjustable, set through the potentiometer on the front panel, divided into two levels: x1 (0… 1s) and x10 (0… 10s), which can avoid false alarms (such as instantaneous current fluctuations during motor start-up) according to the on-site load characteristics.

Warning delay: 0s or 1s optional (DIP switch switching), quickly responding to potential risks while considering system stability.

Precision measurement mechanism:

Measurement core: Built in ø 18mm inner diameter measuring current transformer, using electromagnetic induction principle to monitor residual current, measurement results are almost unaffected by system load current and rated voltage, with strong stability.

Current type adaptation: It can accurately monitor 50Hz AC current, smooth DC current, positive and negative half wave pulsating DC current, phase controlled half wave current (delay angle 90 ° el/135 ° el), and half wave current with 6mA smooth DC superimposed, suitable for complex load scenarios.

(2) Operation and display functions

Multi functional operation button:

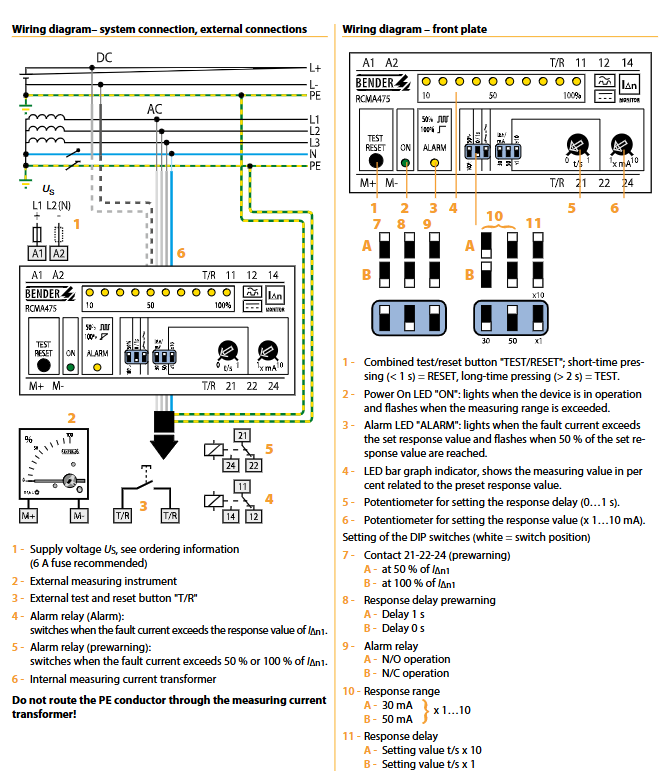

Built in combination “TEST/RESET” button: short press (<1s) for reset function, used to clear fault memory; Long press (>2s) is the testing function to verify whether the device monitoring and alarm circuit is working properly.

External Expansion: Supports connecting external test/reset buttons, with no hard limit on cable length, suitable for remote operation scenarios (such as operating outside the control cabinet).

Visual display system:

Power On LED: When the device is running normally, it stays on and flashes when the measured value exceeds the set range, providing quick feedback on the device’s working status.

Alarm LED: It stays on when the alarm threshold is reached and flashes when the warning threshold is reached, visually distinguishing between warning and alarm states.

LED bar chart indicator: displays the proportion of measured residual current to the set threshold at a scale of 0… 100%, with a total of 10 levels. It visualizes the trend of current changes in real time, making it easy for on-site personnel to quickly determine the level of risk.

Fault memory function: The alarm status is automatically stored inside the device and will not be lost even if the power is cut off. It needs to be cleared through a reset operation for easy fault tracing and cause analysis.

(3) Output and extension functions

Dual independent alarm relay:

Configure 2 conversion contacts (1 normally closed+1 normally open), support N/O (normally open) or N/C (normally closed) operation mode switching (DIP switch setting), can link warning and alarm circuits separately (such as warning trigger indicator light, alarm cut-off main power supply), adapt to different control logic requirements.

Relay parameters: rated contact voltage 150V AC/DC, rated current 5A, making capacity 2A (AC 230V, cos φ=0.4), breaking capacity 0.2A (DC 220V, L/R=0.04s), electrical life up to 12000 cycles, high reliability.

External device expansion:

Support connecting external measuring instruments, the device provides 0… 400 µ A current source output (corresponding to 0… 100% residual current ratio), load resistance ≤ 12.5k Ω, and can be connected to industrial grade display instruments for centralized monitoring.

Transparent sealing cover design: The front panel is equipped with a sealable transparent cover to prevent misoperation or malicious tampering of parameters, suitable for installation needs in industrial sites and public areas.

Detailed technical parameters

(1) Electrical parameters

Insulation and voltage resistance:

Rated insulation voltage: AC 250V, in compliance with IEC 60664-1 insulation coordination standard.

Rated impulse withstand voltage: 4kV, pollution level 3, with strong resistance to power grid surges and interference.

Power supply specifications:

Supply voltage (by model): RCMA475LY(230V AC/DC)、RCMA475LY-13(90…132V AC/DC)、RCMA475LY-21(9.6…84V AC/DC)、RCMA475LY-23(77…286V AC/DC), The 230V model is suitable for industrial and civilian scenarios, while the other models are designed specifically for industrial applications and can be customized with other power supply voltage versions as needed.

Working range of power supply voltage: 0.85… 1.1 x rated power supply voltage, suitable for voltage fluctuations in the power grid.

Power supply frequency range: DC/50… 60Hz, universal AC/DC power supply, suitable for different power supply environments.

Equipment power consumption: ≤ 3.5VA, low-power design, reducing long-term operating costs.

Measurement accuracy and response characteristics:

Relative uncertainty of response value: ≤ 25%, small measurement error, high data reliability.

Lag characteristic: about 25% of the response value, avoiding frequent alarms caused by small fluctuations in current and improving system stability.

Response time: ≤ 70ms when the residual current is 1 times the alarm threshold (tv=0s); ≤ 40ms when the residual current is 5 times the alarm threshold (tv=0s), quickly respond to fault current and reduce safety risk exposure time.

(2) Environmental and mechanical parameters

Environmental adaptability:

Working environment temperature: -25…+70 ℃, can withstand severe cold and high temperature industrial environment.

Storage environment temperature: -40…+75 ℃, suitable for extreme temperature conditions of long-distance transportation and long-term storage.

Climate grade: DIN IEC 60721-3-3 (3K5), suitable for industrial scenarios with high dust and humidity.

Impact resistance: 15g/11ms during operation (IEC 60068-2-27), 40g/6ms during transportation (IEC 60068-2-29), vibration resistance: 1g/10… 150Hz during operation, 2g/10… 150Hz during transportation (IEC 60068-2-6), sturdy structure, strong resistance to harsh environments.

Mechanical structure:

Installation method: Supports screw installation (2 M4 screws, hole diameter 4.3mm) and DIN rail installation (compliant with IEC 60715 standard), can be embedded in standard distribution cabinets (compliant with DIN 43871 standard), and the installation position is not limited.

Shell specifications: Model X475, made of polycarbonate, with a flame retardant rating of UL94V-0, dimensions of 99mm × 91mm × 45mm (length × width × height), weight ≤ 350g, compact size, easy to install densely.

Protection level: The internal components and terminals have a protection level of IP30 (IEC 60529) to prevent solid foreign objects from entering.

(3) Wiring and connection parameters

Wiring terminals: Modular terminals are used, supporting rigid conductors (0.2… 4mm ²), flexible conductors (0.2… 2.5mm ²), and flexible conductors with/without plastic sleeves (0.25… 2.5mm ²), compatible with AWG 24… 12 specification conductors, with firm wiring and reliable contact.

Key wiring requirements:

The built-in measuring current transformer only passes through the phase line (L1, L2, etc.) and neutral line (N). PE conductors are strictly prohibited from passing through the transformer, otherwise it may cause measurement errors or equipment failure.

It is recommended to connect 6A fuses in series in the power supply circuit to protect the equipment from damage caused by power overcurrent.

External testing/reset buttons and external measuring instruments need to be connected to the corresponding terminals according to the wiring diagram to ensure stable signal transmission.

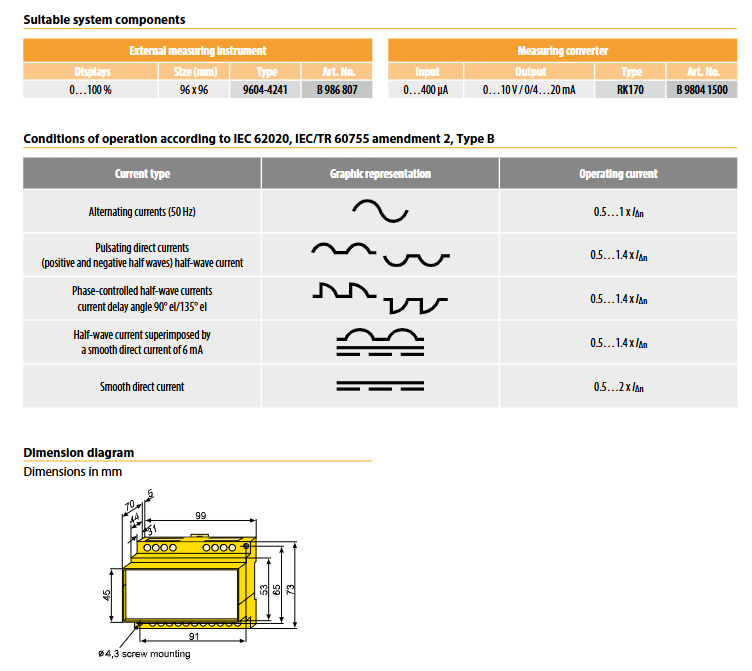

Working characteristics of different current types

RCMA475LY has strong adaptability to different types of fault currents, and the working current range (relative alarm threshold I Δ n) is as follows to ensure monitoring reliability in complex load scenarios:

Specific description of current type, working current range (relative to I Δ n), typical application scenarios

AC current 50Hz sine wave AC current 0.5… 1 × I Δ n for ordinary motors and lighting loads

Pulsating DC current positive and negative half wave pulsating DC (including half wave rectified current) 0.5… 1.4 × I Δ n single-phase rectified charger

Phase controlled half wave current delay angle of 90 ° el/135 ° el for phase controlled rectification current 0.5… 1.4 × I Δ n thyristor speed control equipment

Half wave current of mixed DC current combined with 6mA smooth DC, 0.5… 1.4 × I Δ n rectified load with filtering

Smooth DC current Pure DC fault current 0.5… 2 × I Δ n Battery powered equipment, DC-DC converter

Model specifications and ordering information

(1) Core model differentiation

Products are classified into models based on power supply voltage, and different models are suitable for different power supply scenarios. When ordering, it is necessary to clearly specify the model and order number:

Model, Supply Voltage Range, Applicable Scenarios, Order Number

RCMA475LY 230V AC/DC Industrial Application+Civil Building B 9404 2002

RCMA475LY-13 90… 132V AC/DC Industrial Application B 9404 2004

RCMA475LY-21 9.6… 84V AC/DC Industrial Application B 9404 2014

RCMA475LY-23 77… 286V AC/DC Industrial Application B 9404 2015

Note: Other power supply voltage versions can be customized according to users’ special needs. Please contact the manufacturer for confirmation.

(2) Recommended supporting components

To expand the functionality of the device, manufacturers provide dedicated supporting components that can be selected according to actual monitoring needs:

Component Name Function Description Model Order Number Key Parameters

External measuring instrument 0… 100% residual current ratio display 9604-4241 B 986 807 size 96 × 96mm, compatible with standard instrument panel installation

Measurement converter signal conversion (input → output) RK170 B 9804 1500 input 0… 400 µ A, output 0… 10V or 4… 20mA, compatible with PLC and DCS centralized monitoring systems

Installation and Operation Guide

(1) Installation points

Installation location: Choose an area with good ventilation, away from heat sources and strong electromagnetic interference sources, such as inside the distribution cabinet. The installation direction is not limited to ensure that the front panel is easy to operate and observe.

Wiring specifications: Strictly follow the wiring diagram to connect the power line, signal line, and load line. PE conductors must not pass through the built-in measuring current transformer. After wiring is completed, tighten the terminal screws to avoid loosening and poor contact.

Protective measures: The sealed transparent cover should be locked after the parameter settings are completed to prevent unauthorized personnel from tampering with the settings; Outdoor or dusty environments require additional protective covers to ensure a protection level of no less than IP30.

(2) Parameter setting steps

Threshold setting: Adjust the alarm threshold (30… 500mA) through the “x mA” potentiometer on the front panel. Rotate clockwise to increase and counterclockwise to decrease.

Mode switching: Set the warning ratio (50%/100% I Δ n1), warning delay (0s/1s), and relay mode (NO/NC) through DIP switches, with the white end of the switch indicating the effective position.

Delay setting: Adjust the alarm delay through the “t/s” potentiometer, switch the x1/x10 gear to select the delay range (0… 1s or 0… 10s).

Function test: Long press the “TEST/RESET” button (>2s) to start the test. The device should trigger the alarm relay action, and the LED bar graph should respond synchronously with the Alarm LED. After verifying that the device is functioning properly, short press to reset.