Woodward DSLC Digital Synchronizer and Load Controller

Basic Information

Product positioning: Suitable for microprocessor control equipment of three-phase AC generators, replacing traditional analog control

Functional differentiation: Full functional models including VAR/PF control and process control; Simplified functional model: No independent VAR/PF, process control

Suitable for electrical specifications PT configuration: 120/240V star (Y)/open delta; CT rated: primary current compatible with 5A secondary

Power supply requirements: Input voltage of 18-40Vdc (maximum 77Vdc withstand for 5 minutes), power of 18W, maximum current of 1A

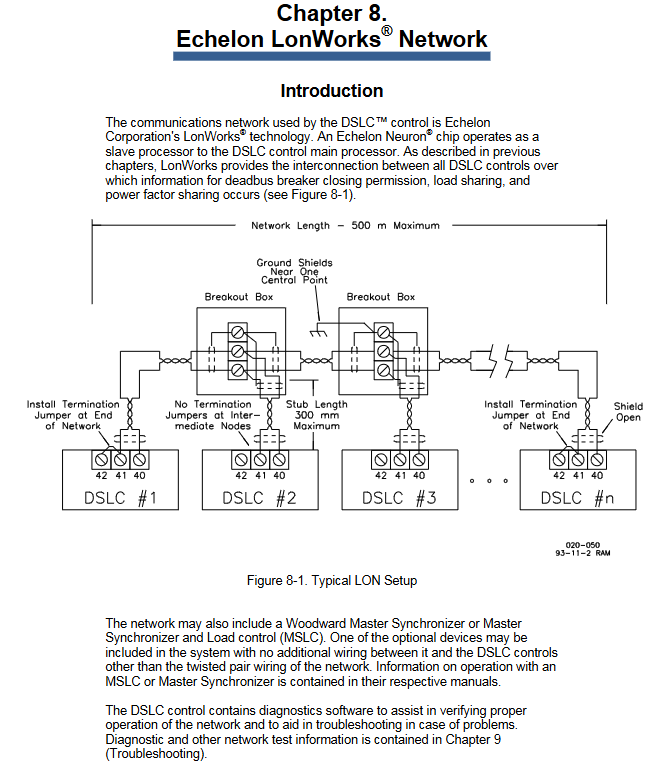

Networking capability supports LonWorks ® Network, communication with up to 16 DSLCs, maximum network transmission distance of 500m

Detailed explanation of core functions

(1) Synchronous control

control mode

Off: Synchronization function disabled; Check: Synchronize matching but do not output closing command; Permissive: only verifies synchronization conditions; Run: Normal synchronization+closing command output

Key functions

Synchronization method: phase matching (fast synchronization, suitable for backup power supply), slip frequency synchronization (ensuring forward power, slip reference 0-0.25Hz)

Non voltage bus closing: Parameters need to be enabled to avoid multiple machines closing simultaneously through network arbitration. Bus voltage below 40Vac is judged as non voltage

Voltage matching: Automatically adjust the generator voltage to the bus voltage window (0-10%), supports enabling/disabling

Core parameters

Parameter Name Setting Range Default Value Unit

Slip frequency reference 0.00-0.25 0.05 Hz

Maximum phase window 2-20 10 °

Circuit breaker delay 0.00-2.00 0.10 s

Closing attempts 1-20 1 times

Voltage window 0.0-10.0 1.0%

(2) Load control

control mode

Core purpose of mode triggering conditions

CB Aux contact disconnection in droop mode, single machine operation or parallel stable

Constant frequency load sharing CB Aux closed+base load/process control disconnected multi machine parallel load sharing

Basic load mode CB Aux+Basic load+Load/UNload Closed fixed load operation

Process Control Mode CB Aux+Load/UNload+Process Control Close Tracking Process Signal

Key functions

Soft loading/unloading: loading time 1-7200s, unloading time 1-7200s, supports slope pause (DI input)

Reverse power protection: instantaneous tripping (-1~-50% load) or delayed tripping (0.1-20s), can be mapped to relay output

Remote load reference: Supports 4-20mA (0-30000kW) or 1-5VDC input, linear interpolation to calculate load target

Core parameters

Parameter Name Setting Range Default Value Unit

Load sag 0.0-100 5.0%

Rated load 0-30000 1000 kW

Unloading trip level 0-30000 0 kW

Loading rate 0.01-100.00 1.00%/s

Reverse power level -1~-50-1.0% load

(3) VAR/PF Control (Full Function Model)

Control mode: disabled (voltage matching only)/PF control (maintaining set power factor)/VAR control (maintaining set reactive power)

Key functions

PF sharing: When multiple machines are connected in parallel, the reactive load is evenly distributed based on the average power factor

Voltage fine-tuning: Maintain the bus voltage within the range of reference value ± voltage regulation rate (1.0-10.0%)

Reactive power limit: The rated kVAR can be set to 60% of the generator kVA (corresponding to a lag PF of 0.8)

Core parameters

Parameter Name Setting Range Default Value Unit

PF reference 0.00 lag -0.00 lead 0.8 lag-

PF dead zone 0.000-1.000 0.025-

Rated kVAR 0-30000 20 (generator side) kVAR

Voltage regulation rate 1.0-10.0 2.0%

Voltage ramp time 1-600 60 seconds

(4) Process Control (Full Function Model)

Adaptation scenarios: cogeneration, power grid import and export control, pressure/liquid level maintenance, etc

Key functions

Signal input: Supports 4-20mA/1-5V process signals, configurable for direct/indirect actions

PID control: proportional gain (0.0001-1000000), integration time (0-20s), dead zone (0-20mA)

Reference adjustment: Local reference (0-20mA) or remote reference (4-20mA), supporting speed adjustment (0.01-20mA/s)

Core parameters

Parameter Name Setting Range Default Value Unit

Process dead zone 0.00-20.00 0.10 mA

Process reference 0.0-20.0 12.0 mA

High limit pickup 0.0-25.0 15.0 mA

Low limit pickup 0.0-25.0 10.0 mA

Process filtering 0.1-5.0 1.0 Hz

Hardware and Communication Configuration

(1) Hardware interface

Key Explanation of Interface Type Quantity/Specification

PT input 3-phase (star/open triangle) 120V (65-150Vac)/240V (150-300Vac)

CT input 3-phase 0-5A rms (maximum 7A), accuracy 0.1% full scale

Discrete Input (DI) 13 channels 18-40Vdc, with a nominal current of 10mA per channel

Relay output (DO) with 8 channels of 200mA current, including circuit breaker closing/opening, alarm and other outputs

Analog input (AI) 2-channel 4-20mA (243 Ω) or 1-5VDC (10k Ω)

Analog output (AO) with 2 speed biases (± 3Vdc/0.5-4.5Vdc, etc.) and voltage biases (± 9Vdc)

(2)LonWorks ® network

Communication speed: 1.25Mbps

Maximum transmission distance: 500m (bus), branch length ≤ 300mm

Number of nodes: up to 64 (0-70 ℃), 20 (-40-85 ℃)

Core functions: Multi machine load sharing, VAR/PF sharing, arbitration of non voltage bus closing authority, remote metering and control

Configuration and Calibration

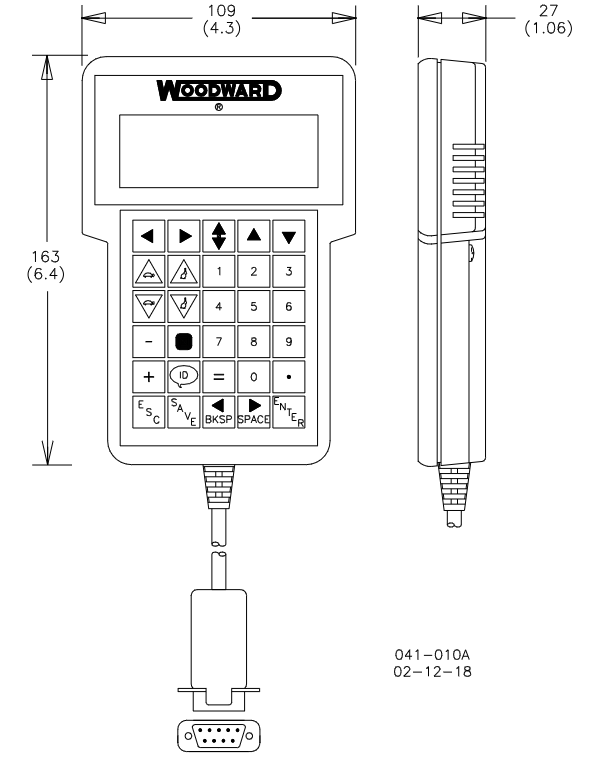

Configuration tool: Handheld programmer (model 9905-292), supporting 10 major menu operations, including parameter adjustment, calibration, and diagnosis

Key calibration steps

Configuration menu (Menu 5): PT ratio, CT rating, system frequency (50/60Hz), network address (1-16)

Synchronous control calibration: slip frequency, phase window, circuit breaker delay

Load control calibration: load sag, loading/unloading time, reverse power protection parameters

Analog calibration: PT/CT sampling calibration, speed/voltage bias zero calibration

Safety Specifications

Electrostatic protection: Discharge before coming into contact with PCB, and do not touch electronic components

CT protection: The CT wiring cannot be disconnected while the engine is running, and a short circuit is required first

Power protection: The polarity of the power supply cannot be reversed, and the voltage should not exceed 77Vdc

Diagnosis and maintenance

Diagnostic function

Menu 0 (Diagnostics): Self test results (normal is 49), network status (number of active DSLCs, number of transmission errors)

Status monitoring: synchronizer mode, load control mode, alarm status (frequency/voltage/load exceeding limit, etc.)

Common troubleshooting

Possible causes and solutions for the fault phenomenon

Unable to power on, power supply not connected/polarity reversal check 18-40Vdc power supply and polarity

Abnormal power factor display, CT/PT phase reversed, CT/PT phase wiring swapped

Correction of incorrect rated load parameters due to uneven load sharing among multiple machines Menu 2 “Rated Load” is the actual rated power of the generator

Synchronization cannot be closed. The phase window is too small/the circuit breaker delay is improper. Adjust the maximum phase window (≥ 5 °) to match the actual closing time of the circuit breaker

Maintenance support

Repair: Contact Woodward authorized dealer to provide part number, serial number, and fault description

Replacement parts: The part number on the equipment nameplate (such as 9905-355, etc.) needs to be provided