Baldor BSM series AC servo motor

1、 Comparison of core product line parameters

Product Series Inertia Characteristics Torque Range (Nm) Speed Range (rpm) Protection Level Core Advantages Applicable Scenarios

BSM N series low inertia 0.45-40 1200-10000 IP54 (IP55 with shaft seal) high dynamic response, excellent acceleration performance, precise positioning, high-speed transmission

BSM C series high inertia 1.2-134 1200-10000 IP54 (IP55 with shaft seal) has good load matching, strong economy, inertia load, and continuous operation

SSBSM series low/standard inertia 0.45-3.6 (N-type); 0.9-3.4 (Type C) 4000-10000 IP67 all stainless steel, corrosion-resistant and washable for food processing and hygiene scenarios

BSM25/33 series standard inertia 2.1-15.6 1800-7000 IP54 circular shell, foot/flange dual installation portable device, universal automation

2、 Key technical characteristics

(1) Power performance

Torque output: BSM N series peak torque is 4 times continuous torque, C series is 3 times, meeting high acceleration requirements

Speed adaptation: Rated speed of 1200rpm to 9000rpm at 320Vdc, doubled speed at 640Vdc (maximum speed limit to be confirmed)

Dynamic response: Mechanical time constant as low as 0.24ms (BSM100C series), supporting fast positioning

(2) Structure and Protection

Material and process: neodymium iron boron magnetic steel, epoxy resin encapsulated winding, galvanized hardware, SSBSM adopts 304 shell+416 axis

Protection design: basic IP54, IP55 after shaft seal configuration, SSBSM up to IP67, resistant to 1500psi (103bar) flushing

Temperature adaptation: ambient temperature -29 ℃ -40 ℃, maximum winding temperature 155 ℃, no derating at 1000m altitude

(3) Feedback and Control

Feedback options: Resolver (anti-interference), Incremental Encoder (1000/2500ppr), Absolute Encoder (BiSS/OnDet/SSI/Hiperface), Hall Sensor

Control adaptation: Supports torque/speed/position modes, compatible with EtherCAT/POWERLINK/Modbus TCP protocols

Safety protection: built-in thermal switch (155 ℃± 5 ℃ action), overcurrent protection, anti demagnetization design

3、 Supporting drive and control scheme

Driver series input voltage output current (RMS) control protocol adapted to motor core functions

MicroFlex analog 105-250VAC (1/3 phase) 3A/6A/9A analog/pulse direction BSM N/C series (low power) automatic tuning, anti resonance filtering

MicroFlex e150 105-250VAC (1/3 phase) 3A/6A/9A EtherCAT/Ethernet/IP All Series Small Power Models Safe Torque Off (STO), Dual Encoder

MotiFlex e180 200-480VAC (3-phase) 3A-90A EtherCAT/POWERLINK full series (including BSM132C) 300% overload, multi axis synchronization

Control software – DriveSize+MCSize selection calculation tool

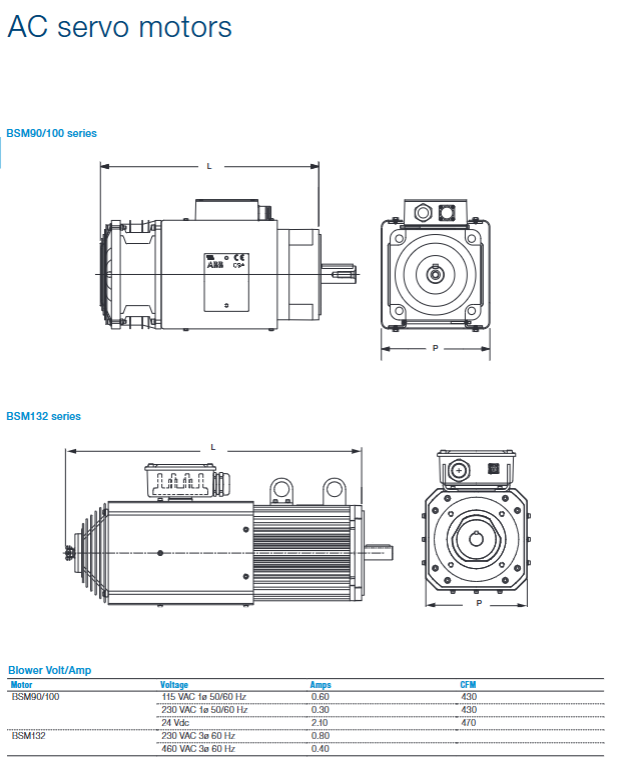

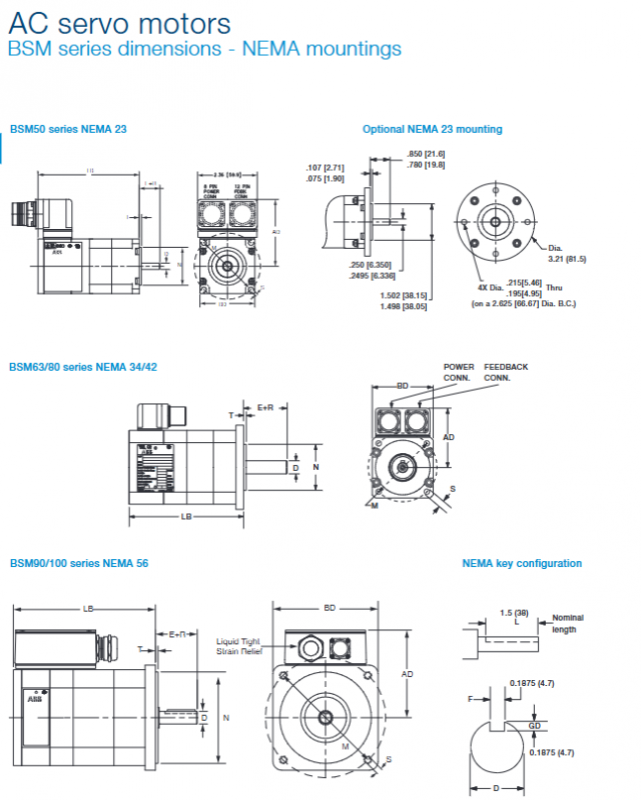

4、 Installation and Dimensional Specifications

(1) Installation standards

IEC framework: 50/63/80/90/100/132, shaft diameter range 9mm-38mm

NEMA Framework: 23 (BSM50N), 34 (BSM63N), 42 (BSM80N/C), 56 (BSM90/100N/C)

Compatible accessories: flange adapter kit, strain relief (M25/M40), rotary connector

(2) Example of Critical Dimensions (IEC)

Motor model, frame length (without brake, mm), shaft diameter (mm), installation hole spacing (mm)

BSM50N 50 101.7-179.5 9 63

BSM80C 80 144.0-220.2 19 100

BSM132C 132 384-536.4 38 265

5、 Selection and Engineering Support

(1) Selection calculation process

Load analysis: Calculate load inertia, friction torque, and acceleration torque

Inertia matching: The recommended ratio of motor inertia to load inertia is 1:1-1:5

Torque calculation: RMS torque=√ [(acceleration torque ² x acceleration time)+(operating torque ² x operating time)+(deceleration torque ² x deceleration time)]/(total time)

Voltage selection: Match the bus voltage of 160Vdc/320Vdc/640Vdc according to the target speed

(2) Engineering resources

Technical documents: 2D/3D CAD files, wiring diagrams, performance curves

Conversion tool: Inertia/torque/length/power unit conversion table

Compliance certification: CE/UL/cUL/BSC/RoHS/WEEE, SSBSM additionally obtained FDA food contact certification