Baldor MicroFlex servo drive

Core parameters of the product

Category key specifications specific parameters

Current specification: Continuous output current of 3A/6A/9A (RMS)

Peak output current 6A/12A/18A (lasting for 0.5 seconds)

Voltage parameter main circuit input 115-230VAC (single/three-phase), wide range of 105-250VAC

Control circuit input 24VDC (compatible with 20-30V), 4A startup impulse current

DC bus voltage 305V (115VAC input)/321V (230VAC input)

Control performance control mode: torque control, speed control, position control (pulse+direction)

Maximum pulse frequency 1MHz (position control)

Feedback resolution SSI encoder up to 262144 counts/rev (18 bits)

Environmental adaptation working temperature 0-45 ℃ (normal), 45-55 ℃ (linear derating)

Storage temperature -40-85 ℃

Humidity limit 93% RH (no condensation)

Installation at an altitude of 1000m (with a capacity reduction of 1.1% for every 100m beyond 1000m)

Installation and wiring specifications

(1) Mechanical installation requirements

Installation method: Vertically installed on the metal backplate to ensure that the heat dissipation surface is in close contact

Spacing requirements: Side ≥ 15mm, up and down ≥ 90mm, front ≥ 60mm (wiring space)

Cooling requirement: 3A model naturally cooled; The 6A model requires forced air cooling at 1m/s; 9A model requires 2.5m/s forced air cooling

Capacity reduction feature: For every 1 ℃ increase above 45 ℃, the output current is reduced by 2%

(2) Electrical wiring details

Power wiring:

Main circuit: L1/L2/L3 connected to input power supply, U/V/W connected to motor winding, R1/R2 connected to regenerative resistor

Protection configuration: Recommend using Ferraz Shawmut series fuses (3A model 10A/8A, 6A model 20A/12.5A, 9A model 25A/20A)

Grounding requirements: protective grounding conductor ≥ 2.0mm ² (copper), maximum grounding leakage current 3.4mA/phase

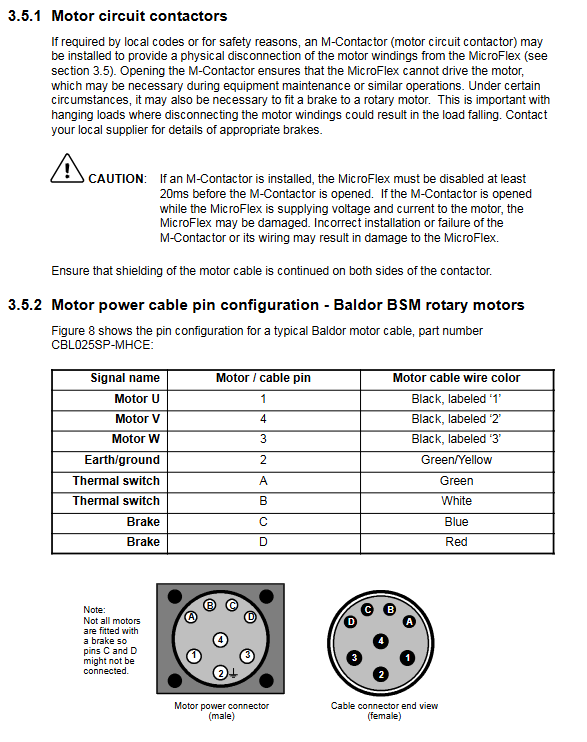

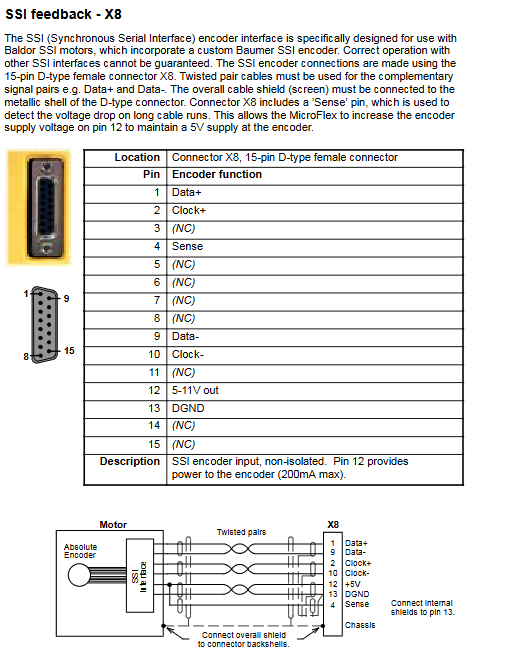

Feedback wiring:

Incremental encoder: X8 interface (15 pins), CHA ±/CHB ±/CHZ ± differential signal, supports Hall signal input

SSI encoder: X8 interface (15 pins), Data ±/Clock ± differential signal, longest cable 30.5m

Signal wiring:

Analog input: X3 interface AIN0 ±, ± 10V range, 12 bit resolution

Digital I/O: X3 interface (driver enable, universal input, pulse+direction, status output)

Serial communication: X6 interface (RS232/RS485), default 57.6Kbaud

(3) Selection of Regenerative Resistors

Minimum resistance: 39 Ω (to avoid overcurrent damage to the driver)

Recommended models: RG56 (56 Ω/44W), RG39 (39 Ω/100W)

Installation requirements: Maintain a safe distance from flammable materials, with a distance of ≥ 50mm above and ≥ 26mm on both sides

Configuration and Debugging Process

(1) Software Tools

Essential software: WorkBench v5 (supporting Windows 95 and above systems)

Hardware requirements: PC requires Intel Pentium 133MHz processor, 32MB memory, 24MB hard drive, serial port (RS232/RS485)

Core functions: Commissioning Wizard, Fine tuning, Parameters, Scope

(2) Debugging steps

Hardware connection: The PC is connected to the driver through a serial port cable (X6 interface), and the 24VDC control power supply and main circuit power supply are connected

Software startup: Install WorkBench v5, create a new project, scan and connect drives

Wizard configuration: Use the Commissioning Wizard to select the control mode, motor model, and feedback type, and automatically complete parameter tuning

Fine tuning optimization: Adjust the gain of the current/speed/position loop using Fine tuning tools and perform testing motion to verify performance

Parameter saving: Save configuration parameters to the non-volatile memory of the drive to avoid power loss

(3) Control mode description

Control mode signal source, core purpose, key parameters

Torque control analog input/software command constant torque output scenario torque constant, current loop gain (KIPROP/KINET)

Speed control analog input/software instruction constant speed operation scenario speed loop gain (KVPROP/KVINT), acceleration/deceleration time

Position control pulse+direction input precision positioning scene electronic gear ratio (FOLLOWNUMERATOR/BOLLOWDENOM)

Troubleshooting and Maintenance

(1) Fault indication and handling

Key points for troubleshooting status LED fault types

Red flashing (1-11 times) corresponds to error codes (1=bus overvoltage, 3=overcurrent, etc.). Check AXISOROR/DRIVEERROR parameters and wiring/load

Red green alternating flashing undervoltage warning. Check if the main circuit power supply is connected and if the DC bus voltage is ≥ 50V

Check the wiring of the 24VDC power supply to ensure that the voltage is within the range of 20-30V when the control power supply fails to light up

(2) Common problem solving

Communication failure: Confirm that the PC serial port selection is correct, use the “scan all serial ports” function, and check the serial port cable wiring

Driver unable to enable: Check if the X3 interface driver enable signal (6/7 pins) is valid and clear the fault status

Motor instability: Reduce the speed loop proportional gain (KVPROP) and confirm that the current loop parameters match the motor

(3) Maintenance points

Regular inspection: Check if the heat dissipation duct is unobstructed, if the temperature of the braking resistor is normal, and if the cable shielding layer is intact

Cable maintenance: The distance between feedback cables and power cables should be ≥ 76mm, avoiding parallel wiring and maintaining a 90 ° angle when crossing

Software maintenance: Regularly backup drive configuration parameters and collect system information using the SupportMe feature

Accessories and Compliance Information

(1) Key accessories

Accessory type, model, example, function, and purpose

Cooling fan FAN001-024 provides forced air cooling for 6A/9A models, with an input of 23-27.5VDC

EMC filter FI0015A00 suppresses electromagnetic interference and complies with CE directive requirements

Regenerative resistors RG56/RG39 consume braking energy to avoid bus overvoltage

Special cable CBL030SP-MHCE motor power cable/feedback cable, with shielding layer

(2) Compliance requirements

CE compliance: EMC filter needs to be installed, motor cable length ≤ 30m, shielding layer grounded 360 °

EMC compliance: Complies with EN61000-6-3 (residential/commercial environment) and EN61000-6-4 (industrial environment) standards

Wiring requirements: Power cables and control cables should be arranged separately, intersecting at a 90 degree angle to reduce electromagnetic interference