Watlow 1/4 DIN specification 8-loop independent PID controller

Core specification parameters

Enter relevant information

Analog input: 8-channel solid-state differential input, optically isolated (120Vac between inputs, 175Vac to ground), A/D converter with integral voltage frequency conversion

Sensor support: thermocouple (J/K/T/B/S/R/N, range -450~3210 ° F), RTD (2 ranges, RTD1: -100~300 ° C, RTD2: -120~840 ° C), 4-20mA current input, infrared non-contact sensor, etc

Resolution: 0.02% (>12 bits), Accuracy: 0.05% (at 25 ° C), Update Frequency: 2 times per second/per input channel

Control and output related

Control circuit: 8 independent circuits, dual outputs (main output/secondary output)

Control modes: On/Off, P, PI, PID, supporting reverse (heating)/forward (cooling) actions

Digital output: 31 channels (1 global alarm+30 alarm/event outputs)

Digital input: 12 channels (for Ramp/Soak triggering)

Pulse input: 1 channel/unit, open collector, frequency 1-20KHz

communication-related

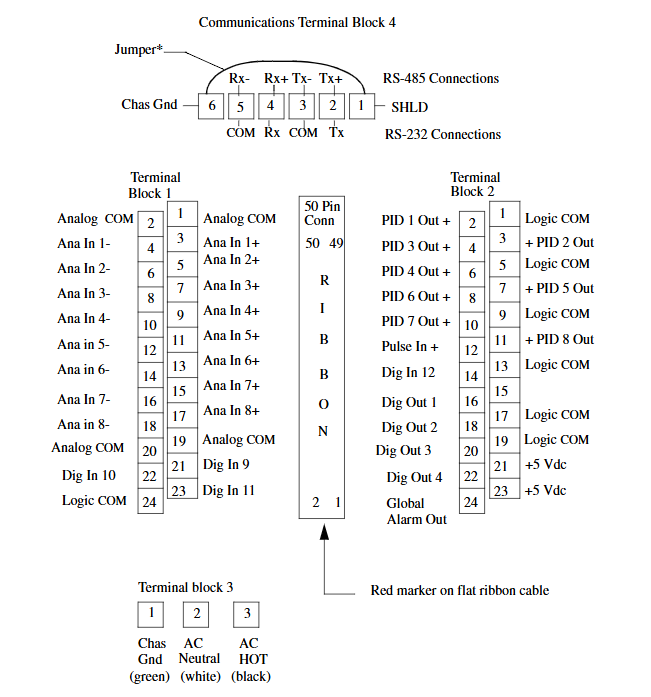

Interface type: RS-232 (1 controller) or RS-485 (4 wires, up to 32 controllers), jumper selection

Baud rate: 2400 or 9600 (menu optional), protocol: ANSI X3.28-1976 compatible, error check: BCC or CRC

Installation Guide

Installation preparation

Panel opening size: 96mm × 96mm (1/4 DIN specification), heat dissipation space needs to be reserved

Safety requirements: Disconnect the power supply before installation and use external safety devices (such as high and low temperature protection) to avoid dangerous working conditions

Wiring specifications

Wire gauge requirements: Priority should be given to using 20/22 AWG stranded wire, allowing 16/18/24 AWG and prohibiting wires that are too thin or too thick

Shielded wire usage: Input/output wires need to be shielded and grounded at one end (at the 8LS panel or sensor end)

Cable recommendations: Special extension cords for thermocouples, Belden # 9154/8451 for analog inputs, Belden # 9729/9842 for RS-485, etc

Noise suppression: When driving electromagnetic relays with digital outputs, an RC absorption network (0.01 μ F capacitor+47 Ω resistor) or MOV device should be added

terminal connection

Main output: TB terminal block (supports analog 0-5V/4-20mA or digital output)

Secondary output: 50 pin ribbon cable (supports distributed zero crossing trigger DZC output)

Communication terminal: TB4 terminal block, with clear definition of RS-232/RS-485 wiring and attention to polarity

Operation and Settings

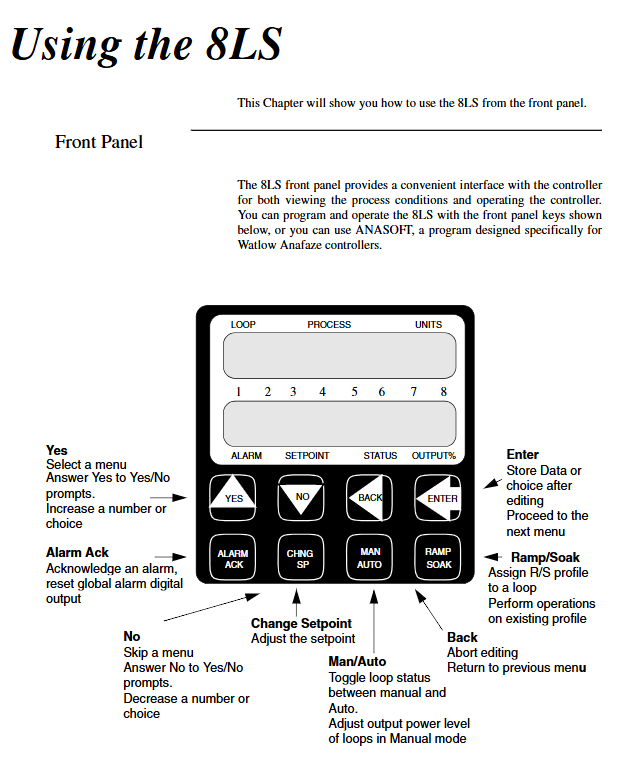

Front panel operation

Key functions: YES/NO (menu selection), ENTER (confirm storage), BACK (return), ALARM ACK (alarm confirmation), CHNG SP (modify set value), etc

Display mode: default bar chart display (8-loop deviation), single loop display, scan display, alarm display (flashing prompt)

Basic operations: setting value modification, manual/automatic mode switching, Autotune self-tuning (automatic calculation of PID parameters)

Core Settings Menu

Global parameters: Store/restore 8 job programs, panel lock, controller address (1-32), AC line frequency (50/60Hz)

Input settings: Sensor type selection, pulse sampling time (1-20 seconds), linear scaling (automatic calibration of 2 measurement points input), input offset (-300~+300)

Control settings: proportional band of hot/cold output (PB), integration time (TI: 0-5000 seconds), differentiation time (TD: 0-255 seconds), output filtering, hot/cold output interval

Output settings: Output type (TP/DZC/O/F/ANA), cycle (1-255 seconds), output limit (0-100%), output action mode

Alarm settings: high/low process alarm, deviation band alarm (0-255), alarm dead zone (0-255), alarm delay (0-255 seconds), alarm output allocation (0-30)

Advanced features

Ramp/Soak program

Ability: 8 programs, up to 20 segments per program, supporting hour/minute or minute/second time benchmarks

Function: Segment triggering (up to 2/segment), segment events (up to 4/segment), program repetition (1-99 times or continuously)

Operation: Program allocation, start/pause/reset, tolerance alarm (0:00~9:59)

8LS-CP Carbon Potential Control

Application: Control the carbon potential (0.10~1.40%) or dew point (-40~300 ° F/C) of the hardening/sintering furnace

Configuration: 1-4 carbon potential circuits, each requiring 2 standard circuits (1 reference thermocouple+1 carbon probe input)

Special functions: probe ablation (with an interval of 1-255 hours or contact activation, ablation time of 1-45 minutes), trim gas temperature alarm (1400-2400 ° F)

Cascade control

Principle: The main circuit output serves as the slave circuit set value, with 0% corresponding to the slave circuit low set value and 100% corresponding to the slave circuit high set value

Configuration: Select the main circuit and set the high and low end settings of the slave circuit (adapted to the input type range of the slave circuit)

Troubleshooting

Independent system issues

No display: Check 120Vac power supply

Abnormal control output: Test output in manual mode, verify with LED or multimeter

Digital I/O fault: Check the input status (1=high/0=low) and test the output switch status through the Test I/O menu

Computer monitoring system issues

Communication failure: Check cable connection, baud rate/protocol matching, controller address uniqueness

ANASOFT software issues: Verify installation path, file integrity, memory (requires 640K free memory), software key installation

Multi controller conflict: Ensure that each controller has a different address (1-32), and reload the job program after replacing the controller