REXROTH 4WRTE type electro-hydraulic proportional directional valve

The Bosch Rexroth 4WRTE electro-hydraulic proportional directional valve is a pilot control valve with electric position feedback and integrated electronic components (OBE). Its specifications range from 10 to 35, rated flow rate from 25 to 1000 l/min, and maximum working pressure of 350 bar. It is reliable, safe, flexible, and precise, and can achieve position, speed, and pressure control. It supports multiple configurations of external/internal pilot oil supply and return oil, and is compatible with various hydraulic oils such as mineral oil and biodegradable oil. It is suitable for safety related dual channel applications. Installation and commissioning must follow professional specifications.

Product Overview

Product type: 4WRTE pilot operated directional control valve, equipped with electric position feedback and integrated electronic components (OBE), belonging to Bosch Rexroth hydraulic component series.

Core strengths

Reliable: Adopting a mature and sturdy structural design.

Safety: The main valve control chamber is automatically pressure compensated by the pilot valve; The main valve core can be spring centered or biased; NG16-35 specifications offer optional valve core position monitoring function.

Flexible: Supports three types of control scenarios: position, speed, and pressure.

Precision: Response sensitivity ≤ 0.05%, hysteresis ≤ 0.1%, zero calibration error ≤ 1%.

Application scope: It can be used as a shutdown component for safety related dual channel applications, complying with EN 13849-1 Cat3 PL d/Cat4 PL e standards and meeting EN 60204 safety start suppression requirements.

Key technical parameters

(1) Basic specifications and hydraulic parameters

Specific indicators for parameter categories

Specification range NG10, 16, 25, 27, 32, 35

Maximum working pressure for main valve P/A/B ports: 350 bar (270 bar for NG27); Pilot valve: 25~315 bar

Rated flow rate (Δ p=5bar) 25~1000l/min (different specifications correspond to different flow rates, such as NG35 reaching 1000l/min)

Maximum recommended flow rate up to 3000l/min (NG35)

Hydraulic oil requires mineral oil (HL/HLP, etc.), biodegradable oil (HETG/HEES, etc.), and fire-resistant oil (HFC, etc.); Viscosity 20~380mm ²/s, temperature -20~+80 ℃

Oil cleanliness ISO 4406 18/16/13 level

(2) Electrical parameters

Power supply voltage: 24VDC (allowable range 18~35VDC), rated power consumption 72VA (average 24VA).

Signal interface: Supports ± 10V (A1), 4-20mA (F1), and ± 10V (A5) with enable signal.

Protection level: IP65 (after connector installation and locking).

Position monitoring: Inductive position switch, 4-pin M12 connector, PNP output, response delay ≤ 15ms.

Principles of Structure and Function

components

Valve body assembly: including main valve core, optional valve core position monitoring module.

Integrated electronic components: equipped with a main valve core inductive position sensor, optional electronic protective film (-967 model, suitable for high humidity/temperature cycling environment).

Pilot control valve: including proportional solenoid and pilot valve core position sensor, to achieve closed-loop control of the main valve core.

working principle

Power off state: The proportional electromagnet loses power, and the main valve core is reset to the neutral position through the centering spring and pressure feedback.

Power on control: By changing the current of the electromagnet to control the displacement of the pilot valve core, the position of the main valve core can be adjusted to achieve flow/direction control.

Closed loop control: Integrating electronic components to compare command values with actual valve core positions, achieving precise adjustment.

Pilot oil configuration mode

Configuration code: Pilot oil supply, pilot oil return, installation requirements

No code, external connection is required for X (supply) and Y (return) ports

Internal E (main valve P port) external sealing X port

T External Internal (Main Valve T Port) Block Y Port

Internal blockage of ports X and Y within ET

Selection and ordering

Order code rules: There are a total of 17 codes, covering key information such as specifications, flow characteristics, interface types, sealing materials, etc., such as 4WRT E 4X/6E/*.

Flow characteristics: divided into linear (L) and linear (P) with fine control segment.

Sealing material: NBR or FKM, to match the type of hydraulic oil.

Installation and Debugging

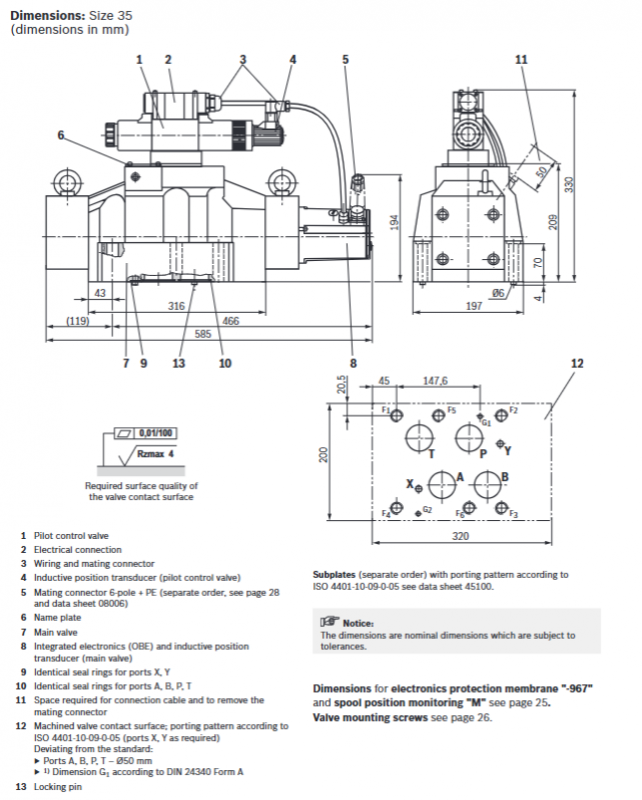

Installation requirements: Priority level installation; The roughness of the installation surface must meet Rzmax 4; Use installation screws with specified torque (such as M6 × 45 screws for NG10, torque 13.5Nm ± 10%).

Debugging taboos: Do not disassemble the valve core position monitoring module; Prohibit adjusting the preset zero point of the factory; After replacing the pilot valve or electronic components, professional personnel need to recalibrate the zero point.

Fault handling: When the power supply is interrupted, the main valve core automatically resets to the neutral position, which may cause the actuator to stop urgently, and the impact risk needs to be evaluated.