REXROTH WE 6X series directional valve

The REXROTH WE 6X series directional valve is a direct acting directional valve driven by wet pin electromagnetic drive, covering three passage forms: 3/2, 4/2, and 4/3. It has a rated diameter of 6, a maximum working pressure of 350 bar, a maximum flow DC voltage of 80 l/min, an AC voltage of 60 l/min, and supports multiple voltage specifications such as 24V DC, 110V AC, and 230V AC. It is suitable for hydraulic oils such as mineral oil and biodegradable oil, and has the characteristics of coil rotation of 90 ° and coil replacement without opening the pressure chamber. It can also be manually operated and has valve core position monitoring functions. It is widely used for flow direction control in industrial hydraulic systems.

Product Overview

Product positioning: The WE 6X series is a direct acting electromagnetic directional valve launched by Bosch Rexroth, designed specifically for industrial hydraulic systems. It drives the valve core to change direction through an electromagnetic coil, achieving directional control of hydraulic oil and adjusting the motion state of actuating components such as oil cylinders and hydraulic motors.

core classification

|Classification dimension | Specific type|

|Passage form | 3/2-way (3 main oil ports), 4/2-way (4 main oil ports, 2 working positions), 4/3-way (4 main oil ports, 3 working positions)|

|Reset method | Spring reset (default), no spring reset (code O), no spring reset with positioning (code OF)|

|Voltage specifications | DC: 12V, 24V, 96V, 205V; AC: 110V, 230V (50/60Hz, voltage tolerance ± 10%)|

|Sealing material | NBR (standard), FKM (temperature and chemical resistant medium, need to be selected separately)|

Core strengths

Flexible installation: Supports any installation posture, and the installation surface is compatible with standards such as DIN 24340 Type A and ISO 4401-03-02-05.

Convenient maintenance: The coil can be disassembled and rotated 90 degrees, and can be replaced without opening the pressure chamber, reducing maintenance costs.

Function extension: Optional manual emergency operation, throttling plug-in, valve core position monitoring (inductive switch or proximity sensor).

Environmental adaptation: Suitable for various hydraulic oils such as mineral oil and biodegradable oil to meet the needs of different industrial scenarios.

Key technical parameters

(1) Hydraulic parameters

Parameter Name Indicator Value Remarks

Maximum working pressure (P/A/B ports) 350 bar (5076 psi)-

Maximum working pressure (T port) DC voltage: 210 bar; AC voltage: 160 bar. The T port of the A/B symbol valve is only used as a leakage port

Maximum flow DC voltage: 80 l/min (21 US gpm); AC voltage: 60 l/min (15.8 US gpm) based on HLP46 hydraulic oil, 40 ℃ environment

Hydraulic oil types include mineral oil (HL/HLP), biodegradable oil (HETG/HEES, etc.), polyethylene glycol (HEPG), and other NBR sealing compatible mineral oil/biodegradable oil; FKM seal compatible with HEPG/HEES

Oil temperature range NBR seal: -30~+80 ℃; FKM sealing: -15~+80 ℃ Environmental temperature range: -30~+50 ℃ (NBR)/-20~+50 ℃ (FKM)

The cleanliness of the oil, ISO 4406 20/18/15 level, needs to be ensured through efficient filtration to extend the service life of the valve

(2) Electrical parameters

Parameter Name: DC Voltage Specification: AC Voltage Specification

Rated voltage 12/24/96/205 V 110/230 V (50/60Hz)

Power consumption 30 W (continuous) suction power 220 VA, maintain power 50 VA

Switching frequency 15000 times/hour 7200 times/hour

Switching time (ISO 6403): Pull in for 25~45 ms, release for 10~25 ms, pull in for 10~20 ms, release for 15~40 ms

The maximum surface temperature of the coil is 120 ℃ (248 ° F) and 180 ℃ (356 ° F), which can reach 220 ℃ in case of a fault

Protection level IP65 (K4/K72L/K73L) IP65 (K4/K72L/K73L), IP66A (C4), IP69K (K40)

Structure and functional configuration

Core structure: mainly composed of valve body, valve core, electromagnetic coil, reset spring (optional), and manual operating mechanism (optional).

Valve body: Integrated P (inlet), A/B (working oil port), T (return oil port), following standard installation surface dimensions.

Valve core: Different functional symbols (such as A/B/C/D/E, etc.) correspond to different oil port conduction logics, meeting diverse control requirements.

Electromagnetic coil: Wet pin design, detachable, the coil is fixed to the valve body with a locking nut (tightening torque 4 ± 1 Nm).

Optional feature configuration

Manual override: divided into concealed (standard, code N9) and exposed (code N), the valve core can be operated without power in emergency situations.

Throttle plug-in: It needs to be installed when the switching flow exceeds the performance limit of the valve. The aperture can be selected as 0.8/1.0/1.2 mm, corresponding to different oil ports (P/A/B/A+B/T).

Valve core position monitoring: Supports inductive position switches (QM/QR series) and proximity sensors (QS series) to monitor the “a” and “b” working positions or “0” center position of the valve core.

Electrical connection: independent connection (K4/C4/K40/K72L/K73L) or centralized connection (DL/DKL), some with LED working indicator lights.

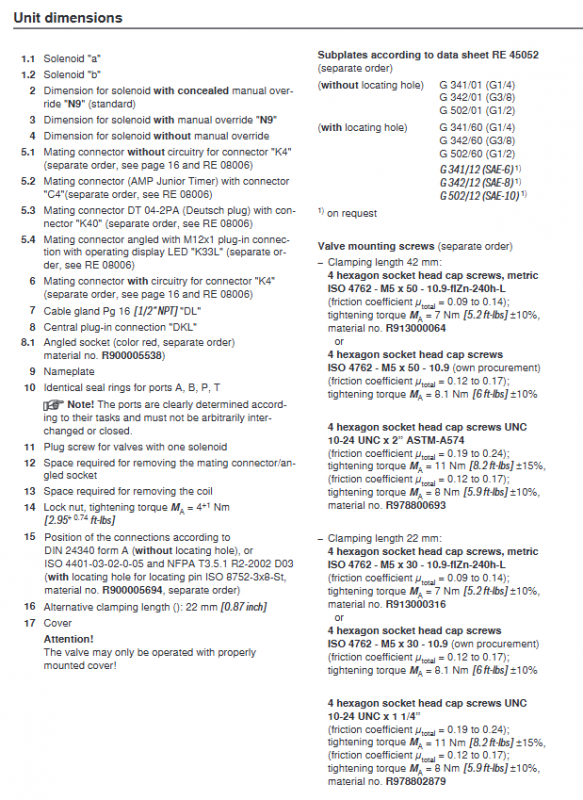

Order Code Rules (Core Field Description)

Example of optional values for field position meaning

Number of channels: 3 (3/2), 4 (4/2 or 4/3)

2-way diameter specification 6 (Size 6)

3 Valve core function symbols A, B, C, D, E, EA, EB, etc. (see page 4 of the document)

4 component series 6X (60~69 series, with unchanged installation dimensions)

5 reset methods without code (spring reset), O (no spring), OF (no spring with positioning)

6-coil type E (high-performance wet pin detachable coil)

Voltage specifications G24 (DC 24V), W110 (AC 110V), W230 (AC 230V)

8 manual operation N9 (concealed), N (exposed), no code (none)

9 Electrical connection methods K4, C4, K40, K72L, K73L, DL, DKL, etc

10 sealing materials/throttling inserts without code (NBR), FKM (FKM seal), B08 (P port throttling 0.8mm), etc

Installation and maintenance specifications

Installation requirements

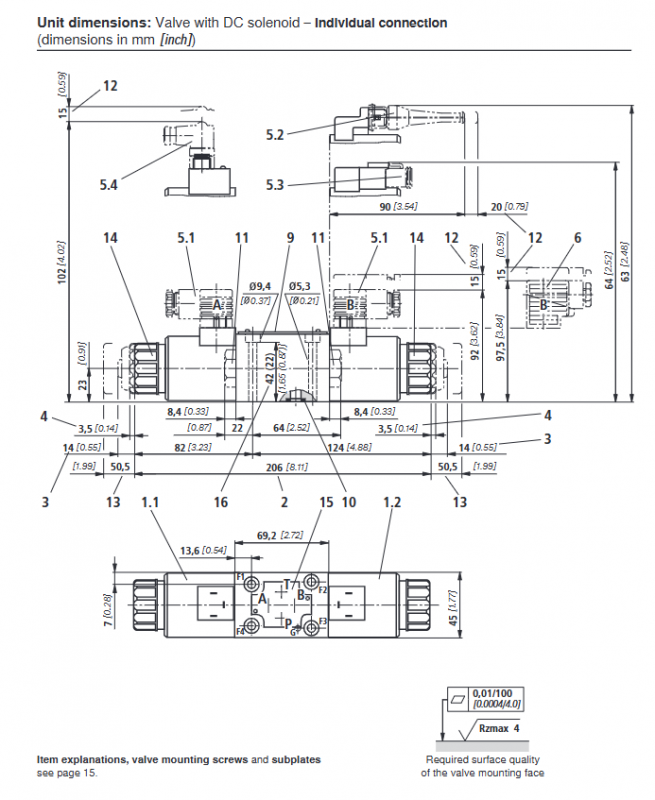

Installation surface: Surface roughness Rzmax 4, flatness 0.01/100 mm, requires the use of specified installation screws (M5 specification, tightening torque 7-8.1 Nm).

Wiring: The electrical connection of the coil needs to be grounded with a protective earth wire (PE), and the AC voltage coil needs to be equipped with a “K” characteristic circuit breaker (with a tripping current of 8-10 times the rated current for 0.6 seconds).

Oil port connection: P/A/B/T oil ports cannot be interchanged or blocked at will, and must be connected correctly according to the valve core function symbol.

Maintenance points

Coil replacement: There is no need to disassemble the valve body. Release the locking nut to remove the coil, and tighten the locking nut after replacement.

Manual operation: Only used when the fuel tank pressure is ≤ 50 bar, special tool (material number R900024943) is required, and violent operation is prohibited.

Cleaning and maintenance: Regularly check the cleanliness of the oil to avoid impurities causing the valve core to get stuck; Clean the valve body only with a dry cloth and do not use corrosive cleaning agents.