Honeywell Expert PKS Universal Process Cabinet

Product basic information

Core positioning: UPC is a remote I/O cabinet for the Expert PKS system, used to deploy Series-C UIO-2/LLAI modules on site far away from the C300 controller, achieving distributed signal acquisition and control. It can replace traditional grouping cabinets and adapt to green field (new construction) and brown field (renovation) projects.

Physical and protective characteristics

|Project | Specification Parameters|

|Material | 316L stainless steel, corrosion-resistant|

|Protection level | IP66 (requires IP66 grade cable gland/conduit fittings)|

|Size | 1300mm (height) × 800mm (width) × 400mm (depth)|

|Weight | Typical configuration is approximately 136.4kg (300lbs)|

|Environmental adaptation | Complies with ANSI/ISA-S71.04 GX level (harsh environment), supports outdoor installation (requires sunshade)|

Environment and Certification

Working temperature: -40 ℃~+55 ℃ (no additional cooling/heating required), storage temperature compatible with industry standards

Humidity range: 10%~95% (no condensation), vibration/impact resistance meets industrial standards

Core certifications: Hazardous Area Certification (cCSAus, ATEX, IECEx), CE Compliance (2014/24/EU ATEX, 2014/30/EU EMC, 2014/35/EU LVD, 2011/65/EU RoHS)

Core configuration and functions

1. Power system

Configuration options: Supports 3 types of redundant AC/DC power supplies, with specific parameters as follows:

|Power type | Model | Output current | Key characteristics|

|ATDI | 51198685-100 | 20A | Redundant design, supporting power rack installation|

|ATDI | FC-PSUN2424 | 25A/600W | High power output, suitable for heavy-duty scenarios|

|Phoenix Contact | Quint4+| 20A | AC/DC or DC/DC optional, strong stability|

Power supply specifications: AC input voltage 100-240V AC (47-63Hz), supports redundant AC main power supply, can achieve 3 UPC daisy chain power supplies through terminal blocks (recommended wire diameter 14AWG, maximum 10AWG)

Protection function: equipped with polarity reversal protection, overload protection, short circuit protection, and independent fuses

2. I/O modules and capacity

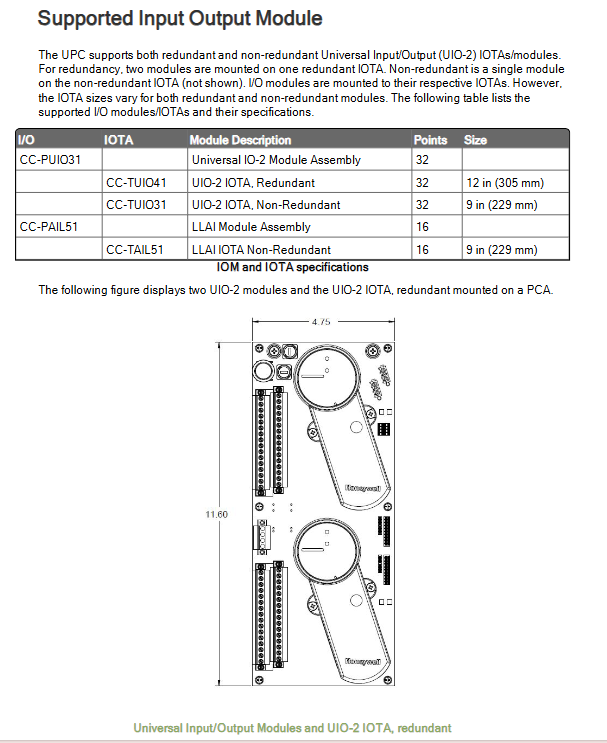

Supporting modules: UIO-2 universal I/O module (32 channels/module), LLAI low-level analog input module (16 channels/module)

Capacity limit: Up to 3 UIO-2 IOTAs (96 channels) or 8 LLAI IOTAs (128 channels)

I/O point configuration: supports 4 combination schemes: 96 IS, 96 Non IS, 64 IS+32 Non IS, 32 IS+64 Non IS

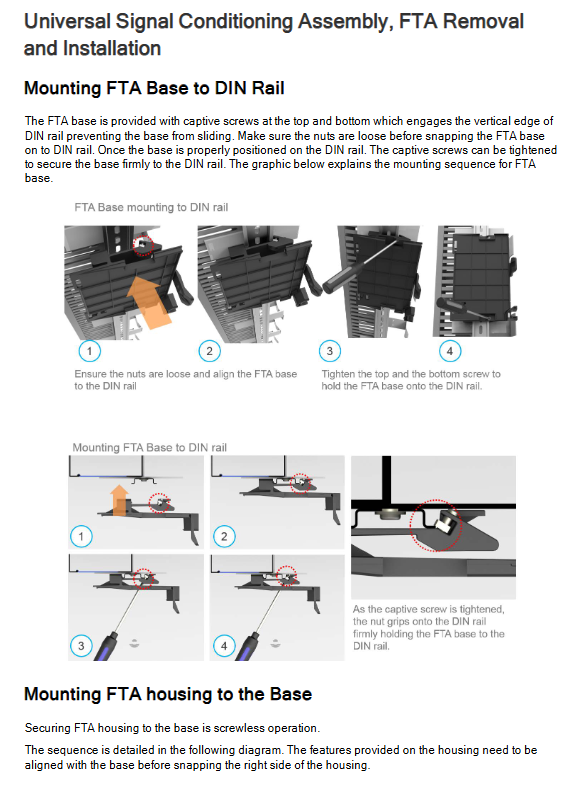

Module installation: redundant IOTA (CC-TUIO41, 12 inches), non redundant IOTA (CC-TUIO31/CC-TAIL51, 9 inches), supporting hot swappable maintenance

3. Communication scheme

UPC supports two mutually exclusive communication methods, adapting to different distances and topology requirements:

Communication solution core component transmission parameter topology support

CN100 IO HIVE CC-IION01 CN100 module, SFP optical module single-mode 10km, multi-mode 2km, copper cable 100m star type, supporting 20 sets of controller allocation

Traditional FOE MOXA EDS-305 series fiber optic extender single-mode 10km, multi-mode 2km star shaped, daisy chain (7 remote points), hybrid topology

Key features: CN100 supports 1280 IO channels, optional ControlSolver license (240/800 points), FOE supports “leapfrog” inter cabinet connections

4. Marshalling scheme

Provide three grouping methods to meet different signal processing requirements:

Grouping type, core components, key functions, applicable scenarios

Universal Marshalling CC-USCA01 signal conditioning component+SCA adapter supports 16 channels, including isolation, relay, and intrinsic safety barrier for general scenarios, requiring signal conditioning/safety isolation

VIPER 51454988 series terminal assembly+IOA accessories 8-channel/module, supporting fuse, disconnect testing, HART transparent transmission of complex signals, requiring flexible configuration of IOA

Weidmuller’s on-site terminal components are passive and direct, supporting 2-wire signals with shielded terminals for simple signals, pursuing low-cost deployment

SCA adapter types: including 11 models such as direct pass, relay input/output, low-level input, analog/digital isolator, intrinsic safety barrier, etc

Installation and deployment specifications

1. Installation prerequisites

Support requirement: The installation structure should bear a load of ≥ 1200lbs and be fixed with M10 × 1.5mm A2-70 grade bolts

Space requirements: There should be no obstruction around the cabinet to ensure heat dissipation. Outdoor installation requires a sunshade (to avoid direct sunlight)

Transportation specifications: horizontally placed on shock resistant trucks, vibration load ≤ 0.5Gs, stacking prohibited

2. Wiring and Grounding

Cable entry: Only bottom entry is allowed, supporting up to 30 cable gland heads, requiring IP66 grade accessories

Grounding requirements: protective grounding (PE) wire ≥ 10AWG, EMC grounding requires 4AWG wire (up to 5 meters long), equipped with safety grounding bar, instrument grounding bar, shielding grounding bar

Wiring isolation: Intrinsically safe (IC level) wiring needs to be physically isolated from other wiring and comply with NEC/CEC specifications

3. Topology configuration

Star topology: Up to 16 FOE units can be connected in parallel to C300, with a maximum single-mode distance of 10km

Chrysanthemum chain topology: up to 7 remote UPCs per channel, maximum 10km for single-mode/2km for multi-mode

Hybrid topology: star shaped (16 columns)+daisy chain (7 rows) combination, supporting up to 40 addresses

Maintenance and Service

1. replaceable unit (ORU)

The core maintainable components include: power module, UIO-2/LLAI module and IOTA, FOE fiber extender, fan component (51454248-100), SCA adapter, fuses, etc

2. Fuse specifications

Fuse type suitable for component voltage and current

Type F Fiber Optic Converter 250V 750mA

Type F 24VDC terminal block 250V 5A

Type T fan+alarm module 250V 375mA

Type T AC terminal block 600V 10A

Type T DC main power terminal block 300V DC 30A

3. Safety maintenance standards

Operating environment: Maintenance is only allowed in non hazardous environments, and opening the lid is prohibited on rainy days/high humidity

Anti static: Before maintenance, it is necessary to connect the ESD bonding point of the cabinet and wear a grounding wristband

Fuse replacement: To operate after power failure, original accessories of the same specifications must be used

Core advantages and application scenarios

Core advantage: Integrated design reduces the need for on-site grouping cabinets; IP66 protection+316L stainless steel suitable for harsh environments; Strong remote deployment capability to avoid insufficient control room space; Redundant power supply and communication enhance reliability; Multiple authentication coverage for use in hazardous areas

Application scenarios: Distributed signal acquisition and control in process industries such as petrochemicals, power, metallurgy, and pharmaceuticals, especially suitable for scenarios where on-site equipment is dispersed, environments are harsh, and remote monitoring is required