“ABB FI830F Fieldbus Module” has been added to your cart. View cart

ABB G3EFa HENF450295R2 Industrial Automation Module

$9,689.00 Original price was: $9,689.00.$5,959.00Current price is: $5,959.00.个

ABB O3EId HENF452777R3 Digital Output Module

$6,436.00 Original price was: $6,436.00.$6,264.00Current price is: $6,264.00.个

ABB B5EEd HENF105082R4 Electronic Motor Protection Relay

$8,886.00 Original price was: $8,886.00.$7,854.00Current price is: $7,854.00.个

ABB B5EED HENF105082R4 is a high-precision, multifunctional electronic motor protection relay based on microprocessor technology, designed to ensure the safe operation of various AC motors in the industrial field. As the “safety guard” of the motor control system, this relay can monitor the operating parameters of the motor in real time (such as current, voltage, temperature, etc.). When overload, phase loss, locked rotor, overvoltage, undervoltage and other faults are detected, it can quickly issue an alarm signal and cut off the power supply of the motor, avoiding the expansion of the fault and causing motor damage or safety accidents.

Category: ABB

Tag: B5EEd HENF105082R4

Description

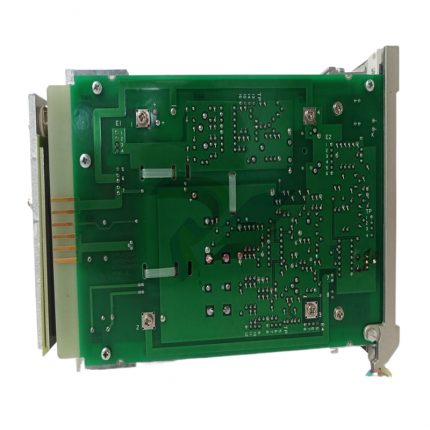

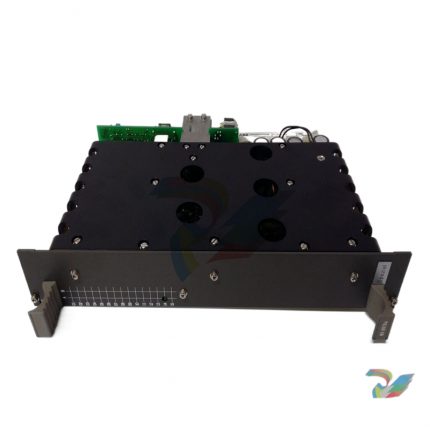

ABB B5EEd HENF105082R4 Electronic Motor Protection Relay

Product Overview

ABB B5EED HENF105082R4 is a high-precision, multifunctional electronic motor protection relay based on microprocessor technology, designed to ensure the safe operation of various AC motors in the industrial field. As the “safety guard” of the motor control system, this relay can monitor the operating parameters of the motor in real time (such as current, voltage, temperature, etc.). When overload, phase loss, locked rotor, overvoltage, undervoltage and other faults are detected, it can quickly issue an alarm signal and cut off the power supply of the motor, avoiding the expansion of the fault and causing motor damage or safety accidents.

This product belongs to the core product series of ABB motor control and protection, which integrates advanced digital signal processing technology and industrial grade hardware design. It has the characteristics of high measurement accuracy, comprehensive protection functions, flexible parameter configuration, and strong anti-interference ability. It has a wide range of motor power adaptability and can be used for the protection of various industrial motors such as water pumps, fans, compressors, conveyors, etc. It is widely used in multiple industries such as power, chemical, metallurgical, water treatment, intelligent manufacturing, etc. It is a key equipment to improve the reliability of motor operation and reduce maintenance costs.

Core functional characteristics

2.1 Comprehensive fault protection function

The B5EED relay is equipped with multi-dimensional protection algorithms, covering common fault types throughout the entire life cycle of motor operation, providing comprehensive safety protection for the motor. Firstly, it adopts inverse time protection characteristics, which can automatically adjust the protection action time according to the rated current and overload multiple of the motor, avoiding short-term overload misoperation and quickly protecting in case of continuous overload; The second is phase loss and imbalance protection, which monitors the three-phase current balance of the motor in real time. When a phase loss or three-phase current imbalance exceeds the set threshold (5% -50% adjustable), the protection is immediately triggered; The third is stall protection. If there is stall during the start-up or operation of the motor, the current will sharply increase. The relay can act within 100ms after detecting the abnormality to prevent the motor winding from burning out.

In addition, the relay also has functions such as overvoltage protection (protection range of 105% -150% rated voltage), undervoltage protection (protection range of 50% -95% rated voltage), ground fault protection (through zero sequence current detection, adjustable protection threshold), and PTC temperature protection (supporting the connection of built-in PTC thermistor in the motor to monitor winding temperature), which can flexibly enable or disable specific protection functions according to different application scenarios.

2.2 High precision parameter measurement and monitoring

Relying on high-precision current transformers and digital signal processing chips, B5EED relays have excellent parameter measurement capabilities, with current measurement accuracy of ± 1% (range 0.1A-100A) and voltage measurement accuracy of ± 1.5% (range 100V-480V). They can real-time collect key parameters such as three-phase current, line voltage, power, power factor, and operating time of the motor. All measurement data is displayed in real-time through the relay’s built-in LCD screen, which supports switching between Chinese/English bilingual interfaces, allowing operation and maintenance personnel to intuitively grasp the motor’s operating status.

The relay also has data recording function, which can store detailed information of the last 10 fault events, including fault type, current/voltage parameters at the time of fault occurrence, fault time, etc., providing strong basis for fault cause analysis and tracing. At the same time, it supports uploading measurement data to the higher-level monitoring system through communication interfaces, achieving remote monitoring and data aggregation of motor operation status.

2.3 Flexible parameter configuration and adaptability

To adapt to different types and powers of motors and diverse application scenarios, B5EED relays provide rich parameter configuration options. Users can configure parameters such as motor rated current (0.1A-100A continuously adjustable), rated voltage (220V/380V/400V/480V optional), starting time (1s-60s adjustable to adapt to different motor starting characteristics), and protection action delay (some protection functions support 0.1s-300s delay settings) through the buttons on the relay panel or dedicated software (ABB Motor Protection Studio).

The relay supports switching between two protection modes: “Standard mode” is suitable for ordinary asynchronous motors, and “Heavy load mode” is suitable for motors with large starting loads such as compressors and crushers, and can be flexibly selected according to the load characteristics of the motor. In addition, its input power range is wide (AC 85V-265V), without the need for additional power transformers, and can be directly connected to commonly used power sources in industrial sites.

2.4 Industrial grade reliability and anti-interference design

In response to the complex electromagnetic environment and harsh working conditions in industrial sites, B5EED relays adopt multiple anti-interference measures in hardware design: internal photoelectric isolation technology is used to electrically isolate the signal acquisition circuit from the control output circuit (isolation voltage ≥ 2500V AC), preventing external interference signals from entering; Through the IEC 61000-4 series electromagnetic compatibility testing, it has strong anti-static (contact discharge ± 8kV, air discharge ± 15kV), anti surge (± 2kV) and anti RF interference capabilities, ensuring stable operation near strong interference sources such as frequency converters and large motors.

The relay adopts an industrial grade shell design, with a protection level of IP40 and a working temperature range covering -20 ℃~+70 ℃. It can withstand extreme environments such as high temperature, low temperature, and humidity; The output contacts are made of silver alloy material and have the on-off capability of 10A/250V AC, with a service life of over 100000 times, ensuring the reliable execution of protection commands.

2.5 Convenient communication and operation and maintenance functions

The B5EED relay is equipped with RS485 communication interface and supports Modbus RTU communication protocol. It can seamlessly integrate with higher-level monitoring systems such as PLC, HMI, SCADA, etc., realizing remote configuration of protection parameters, remote monitoring of motor operation status, and remote transmission of fault signals. Through the monitoring system, operation and maintenance personnel can centrally manage multiple motor protection relays in the central control room, greatly improving operation and maintenance efficiency.

In terms of operation and maintenance, the relay has a complete status indication function, and the panel is equipped with power indicator lights, operation indicator lights, alarm indicator lights, and fault type indicator lights, which can quickly determine the working status of the equipment; Support the “manual testing” function, simulate protection actions through buttons, and verify the reliability of relays and external control circuits; Parameter configuration supports password protection to prevent unauthorized personnel from accidentally modifying key protection parameters.

Key technical parameters

parameter category

Specific parameters

Instructions

Applicable motor types

Three phase asynchronous motor, synchronous motor

Adapt to mainstream industrial motor types

Current measurement range

0.1A-100A (direct access); 1A -1000A (with current transformer)

Wide range coverage, supporting high current motors

Voltage measurement range

100V -480V AC (line voltage)

Adapt to industrial power grids of different voltage levels

measurement accuracy

Current: ± 1%; Voltage: ± 1.5%; Power: ± 2%

High precision measurement provides reliable data for protection and monitoring

protection function

Overload, phase loss, current imbalance, locked rotor, overvoltage, undervoltage, ground fault, PTC temperature protection

Comprehensive coverage of common motor faults

input power

AC 85V – 265V,50/60Hz

Wide voltage input, suitable for unstable power supply environment

Output contact

2 sets of conversion contacts, capacity 10A/250V AC

Support dual output of alarm and trip

communication interface

RS485, Supports Modbus RTU protocol

Realize remote monitoring and centralized management

working environment

Temperature: -20 ℃~+70 ℃; Humidity: 5% to 95% (no condensation); Protection level: IP40

Adapt to harsh industrial site environments

Electromagnetic Compatibility

Compliant with IEC 61000-4-2/3/4/5/6 standards

Strong anti-interference ability to ensure stable operation

Overall dimensions

96mm (length) x 96mm (width) x 78mm (depth)

Standard panel installation size for easy integration

weight

About 400g

Lightweight design, easy installation

Typical application scenarios

4.1 Water pump protection in the water treatment industry

In the pump control system of sewage treatment plants and water plants, B5EED relay serves as the core protection component to monitor the current, voltage, and operating status of the pump motor in real time. When the water pump is blocked due to pipeline blockage, the relay quickly triggers the blockage protection, cuts off the motor power supply, and avoids motor burnout; When there is overvoltage or undervoltage fluctuation in the power grid voltage, an alarm should be promptly issued and the machine should be shut down to prevent damage to the insulation of the water pump motor caused by abnormal voltage. Its RS485 communication function can upload the operation data of multiple water pumps to the water plant monitoring center, achieving centralized monitoring and fault warning of pump operation status, and ensuring the continuous and stable operation of the water treatment system.

4.2 Protection of fans in the metallurgical industry

The key fan equipment in the metallurgical workshop, such as blast furnace fans and converter dust removal fans, have high motor power and harsh operating environments, requiring extremely high protection reliability. B5EED relay provides comprehensive protection for the fan motor: in response to the high starting current of the fan, the starting time parameter is adjusted to avoid triggering overload protection during the starting process; Real time monitoring of motor three-phase current to prevent phase loss faults caused by poor cable contact; Connect the PTC thermistor of the motor winding to directly monitor the temperature of the winding, avoiding damage to the motor due to overheating in high temperature environments. Its anti-interference design can resist strong electromagnetic interference generated by large motors and frequency converters in metallurgical workshops, ensuring reliable triggering of protection functions.

4.3 Intelligent Manufacturing Production Line Motor Protection

In intelligent manufacturing production lines such as automobile manufacturing and electronic component production, conveyor lines, robotic arms, processing equipment, etc. all rely on motor drives, and motor failures will directly cause production line shutdowns. B5EED relays are integrated into the motor control circuit of the production line, and personalized protection parameters are configured according to the motor characteristics of different devices, such as overload and phase loss protection for conveyor line motors and locked rotor and overvoltage protection for robotic arm motors. By communicating with the production line PLC through the Modbus protocol, when the motor fails, the relay uploads the fault signal to the PLC, which immediately controls the relevant equipment to shut down, avoiding the expansion of the fault. At the same time, the fault location and cause are displayed on the HMI, making it easy for operation and maintenance personnel to quickly handle and reduce production line downtime.

4.4 Compressor Protection in the Chemical Industry

The motors of air compressors and gas compressors in the chemical industry are often in a state of heavy load starting and continuous operation, which can lead to problems such as overload, locked rotor, and voltage fluctuations. B5EED relay enables “overload mode” to provide protection for the compressor motor, extending the overload protection action time and adapting to the high current characteristics when the compressor starts; Real time monitoring of motor operating current and voltage, and immediately cutting off the power supply when the compressor is blocked due to valve blockage; When the voltage fluctuation of the power grid exceeds the set range, an alarm signal is issued and the machine is delayed to reserve emergency response time for operators. Its fault recording function can store detailed fault information for each occurrence, providing data support for compressor operation status analysis and maintenance plan formulation.

Installation and configuration points

5.1 Installation specifications

-The relay adopts the standard 96 × 96mm panel installation method, and the installation panel thickness should be between 1mm-8mm. The installation hole spacing is 152mm (horizontal) × 152mm (vertical). During installation, it is necessary to ensure that the panel is flat and avoid tilting the relay;

-The installation location should be chosen in an area with good ventilation, away from high-temperature heat sources (such as heaters and motors), strong electromagnetic interference sources (such as frequency converters and transformers), and corrosive gases, avoiding direct sunlight and rainwater erosion;

-Before wiring, the power supply and motor power supply must be disconnected, and wiring must strictly follow the terminal block markings: the current input terminal needs to distinguish the polarity of the three-phase current, the voltage input terminal needs to be connected to the correct line voltage, and the output contact needs to be connected to the contactor coil of the motor control circuit;

-The current circuit wiring should use copper wires with a cross-sectional area of ≥ 2.5mm ², and the voltage circuit wiring should use copper wires with a cross-sectional area of ≥ 1.5mm ². All wiring terminals must be tightened to avoid measurement errors or protection misoperations caused by poor contact;

-RS485 communication lines should use shielded twisted pair cables, with one end of the shielding layer grounded (grounding resistance ≤ 4 Ω). The communication line should be laid separately from the power cable (spacing ≥ 300mm) to reduce electromagnetic interference.

5.2 Configuration Process

1. Basic parameter configuration: Connect the relay power supply, enter the “Parameter Settings” interface through the panel buttons, configure the rated current of the motor (set according to the motor nameplate or current transformer ratio), rated voltage (matched with the on-site grid voltage), and motor starting time (refer to the motor starting curve, generally set to 1.2 times the rated starting time of the motor);

2. Protection function configuration: Enable the required protection functions (such as overload, phase loss, locked rotor, etc.), set the action threshold and delay time of each protection function (such as setting the current imbalance threshold to 10% and the locked rotor protection delay to 0.2s);

3. Communication parameter configuration: Enter the “Communication Settings” interface and set the RS485 communication address (1-247 adjustable), baud rate (9600bps/19200bps optional, consistent with the monitoring system), data bit and stop bit (default 8-bit data bit, 1-bit stop bit);

4. Password setting: To prevent parameter tampering, enter the “System Settings” interface to set the administrator password (4 digits) and enable parameter protection function;

5. Functional testing: After the configuration is completed, disconnect the motor power supply, simulate various faults (such as overload and phase loss) through the panel “test” button, check whether the relay can trigger alarms and protection actions normally, and verify whether the communication link is normal to ensure that the fault signal can be transmitted to the monitoring system.

Additional information

| Weight | 3 lbs |

|---|---|

| Dimensions | 23 × 21 × 12 in |

Reviews (0)

Be the first to review “ABB B5EEd HENF105082R4 Electronic Motor Protection Relay” Cancel reply

Shipping and Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.