“ABB 64691929 – Spare parts in stock” has been added to your cart. View cart

ABB B5EC HENF105077R1 Electronic Motor Protection Relay

$8,544.00 Original price was: $8,544.00.$8,054.00Current price is: $8,054.00.个

ABB B5EEd HENF105082R4 Electronic Motor Protection Relay

$8,886.00 Original price was: $8,886.00.$7,854.00Current price is: $7,854.00.个

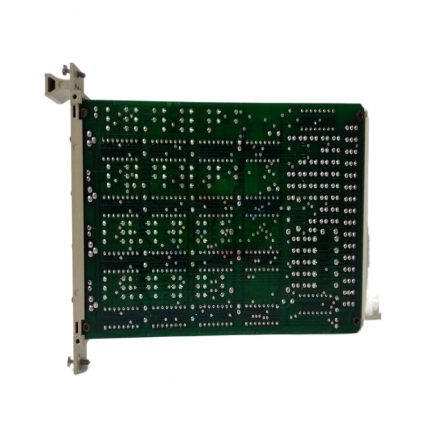

ABB G3EFa HENF450295R2 Industrial Automation Module

$9,689.00 Original price was: $9,689.00.$5,959.00Current price is: $5,959.00.个

ABB G3EFa HENF450295R2 is a multifunctional integrated module designed for mid to high end industrial automation scenarios. It is a core extension component of ABB AC500-S series PLC and focuses on achieving mixed acquisition, precise processing, and reliable control of digital and analog quantities in industrial fields. This module integrates ABB’s core technology in the field of industrial control, with features such as multi signal type adaptation, high anti-interference ability, and flexible expansion. It can seamlessly integrate various industrial sensors, actuators, and upper control systems, providing stable signal processing and control support for automated production lines in industries such as chemical, metallurgical, intelligent manufacturing, and energy.

Category: ABB

Tag: G3EFa HENF450295R2

Description

ABB G3EFa HENF450295R2 Industrial Automation Module

Product Overview

ABB G3EFa HENF450295R2 is a multifunctional integrated module designed for mid to high end industrial automation scenarios. It is a core extension component of ABB AC500-S series PLC and focuses on achieving mixed acquisition, precise processing, and reliable control of digital and analog quantities in industrial fields. This module integrates ABB’s core technology in the field of industrial control, with features such as multi signal type adaptation, high anti-interference ability, and flexible expansion. It can seamlessly integrate various industrial sensors, actuators, and upper control systems, providing stable signal processing and control support for automated production lines in industries such as chemical, metallurgical, intelligent manufacturing, and energy.

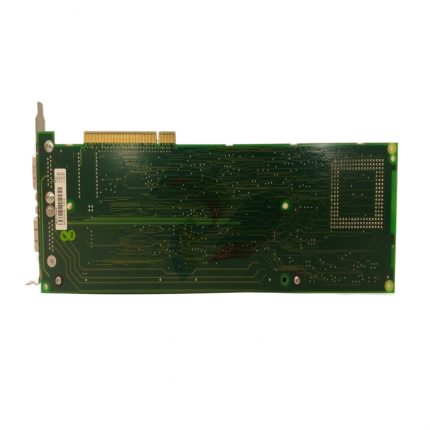

As a key node connecting on-site devices and control centers, the G3EFa module not only supports integrated digital input/output and analog acquisition, but also has fast signal response and local logic processing capabilities, which can effectively reduce the computational load of the upper PLC and improve the real-time and reliability of the entire automation system. Its standardized interface design and modular structure make it easy for users to configure and expand the system according to their actual needs, significantly reducing system integration costs and operational difficulties.

Core functional characteristics

2.1 Mixed signal processing and multi type adaptation

The G3EFa module adopts a mixed integration design of digital and analog signals, with a single module integrating 16 digital input channels, 8 digital output channels, and 4 analog input channels. It can simultaneously process switch signals and continuously changing analog signals, meeting the needs of multi type signal acquisition and control in industrial sites. The digital input channel supports dry/wet contact signal access and is compatible with 24V DC standard industrial signals. It can directly collect status signals from devices such as limit switches, proximity switches, and photoelectric sensors; The digital output channel has the ability to drive loads with 2A/250V AC or 2A/30V DC, and can directly control actuators such as solenoid valves, indicator lights, and small contactors.

The analog input channel supports adaptive connection of 4-20mA current signal and 0-10V voltage signal, with a measurement accuracy of ± 0.1%. It can accurately collect continuous signals output by pressure sensors, temperature transmitters, liquid level sensors and other devices, providing reliable data support for precise control of the production process. Each channel has independent signal conditioning circuits and overcurrent protection functions, effectively avoiding damage to the module core circuit caused by abnormal on-site signals.

2.2 High speed signal response and real-time control

In response to the strict requirements for control timeliness in industrial production, the G3EFa module adopts high-speed signal processing chips and optimized circuit design. The response time of the digital input channel is ≤ 100 μ s, and the action delay of the digital output channel is ≤ 1ms. It can quickly capture the status changes of on-site equipment and execute control instructions in a timely manner, especially suitable for production line beat control, precision machining and other scenarios that require high time accuracy. The module supports adjustable filtering time for input signals (0.1ms-100ms), and users can flexibly set it according to the on-site interference situation, effectively suppressing signal false triggering caused by high-frequency interference.

In addition, the module has local logic processing capability and supports configuring simple logic control rules (such as signal interlocking, threshold comparison, delay action, etc.) through ABB Control Builder Plus programming software. It can achieve autonomous collaborative control of on-site equipment without relying on the upper PLC, reducing the transmission delay of control signals in the system and improving the response speed and reliability of local control loops.

2.3 Industrial grade reliability and strong anti-interference design

In order to adapt to the complex electromagnetic environment and harsh working conditions in industrial sites, the G3EFa module adopts multiple reliability guarantee measures in hardware design: internal photoelectric isolation technology is used to electrically isolate the signal acquisition circuit, control output circuit, and power supply circuit, with an isolation voltage of ≥ 2500V AC, effectively preventing external interference signals from entering and high-voltage signals from counterattacking; Through the IEC 61000-4 series electromagnetic compatibility testing, it has strong anti-static (contact discharge ± 8kV, air discharge ± 15kV), anti surge (± 2kV) and anti RF interference capabilities, ensuring stable operation near strong interference sources such as frequency converters and large motors.

The module adopts industrial grade components and sealed housing design, with a working temperature range covering -25 ℃~+70 ℃, a humidity adaptation range of 5%~95% (no condensation), a protection level of IP20, and can withstand extreme industrial environments such as high temperature, low temperature, humidity, and high dust; The power input supports a wide voltage fluctuation of DC 24V ± 15%, which can adapt to unstable power supply conditions in industrial sites and ensure the continuous and stable operation of the module.

2.4 Flexible Expansion and Convenient Operation and Maintenance

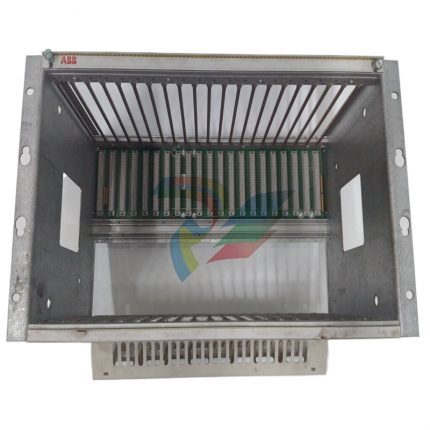

The G3EFa module supports seamless integration with ABB AC500-S series PLCs, enabling high-speed data exchange through the PLC’s backplane bus. It can expand up to 8 modules of the same series to meet the signal acquisition and control needs of production lines of different scales. The module supports hot swappable functionality (in conjunction with the PLC’s hot swappable backplane), allowing for module replacement and maintenance without shutting down the system, significantly reducing production downtime caused by equipment maintenance.

In terms of operation and maintenance, the module is equipped with rich status indicator functions. The front is equipped with power indicator lights, operation indicator lights, and status indicator lights for each channel (lit when the input signal is normal, lit when the output action is active, and flashing when there is a fault). Operation and maintenance personnel can intuitively judge the working status of the module and channel fault conditions through the indicator lights. At the same time, the module supports remote diagnosis through the upper PLC or dedicated debugging software, which can read the working temperature, power supply voltage, channel fault information and other parameters of the module in real time, facilitating preventive maintenance.

Key technical parameters

parameter category

Specific parameters

Instructions

Digital input

16 channels, 24V DC, response time ≤ 100 μ s, filtering time adjustable from 0.1ms to 100ms

Supports dry/wet contact signals and has strong anti-interference ability

digital output

8 channels, relay output, load capacity 2A/250V AC or 2A/30V DC

Directly drive commonly used industrial actuators with overcurrent protection

Analog input

4-channel, supports adaptive 4-20mA current signal/0-10V voltage signal, measurement accuracy ± 0.1%

Accurately collect continuously changing on-site signals

isolation level

Channel isolation 1500V AC, system isolation 2500V AC from ground

Strong isolation protection ensures system security

power input

DC 24V ± 15%, maximum power consumption ≤ 10W

Wide voltage input, suitable for industrial power supply environment

communication interface

Supports ABB AC500-S backplane bus with a speed of ≥ 10Mbps

High speed data exchange with PLC without communication delay

working environment

Temperature: -25 ℃~+70 ℃; Humidity: 5%~95% (no condensation); Protection level: IP20

Adapt to harsh industrial site environments

Electromagnetic Compatibility

Compliant with IEC 61000-4-2/3/4/5/6 standards

Strong anti electromagnetic interference capability to ensure stable operation

Overall dimensions

100mm (length) x 140mm (width) x 32mm (height)

Compact size, supporting DIN 35mm rail installation

weight

About 350g

Lightweight design, easy installation

Typical application scenarios

4.1 Chemical Industry Reactor Control System

In the control system of chemical reaction vessels, the G3EFa module serves as the core signal processing unit, responsible for the acquisition and control of multiple types of signals: collecting status signals of the feed valve, discharge valve, and safety interlock switch of the reaction vessel through digital input channels; Accurately collect key process parameters such as temperature (converted into 4-20mA signal by temperature transmitter), pressure (pressure transmitter outputs 4-20mA signal), liquid level (liquid level transmitter outputs 0-10V signal) inside the reaction kettle through analog input channel; Control the start and stop of the mixing motor, heating device, and cooling water pump through digital output channels. The local logic processing function of the module can achieve interlocking control between temperature and heating device (such as automatically cutting off the heating power when the temperature exceeds the threshold), quickly respond to changes in process parameters, and ensure the safety and stability of the reaction kettle production process.

4.2 Control of Steel Rolling Production Line in Metallurgical Industry

In the metallurgical steel rolling production line, the G3EFa module is used for signal acquisition and action control of the rolling mill unit: the digital input channel collects signals such as the roller position switch, steel plate detection photoelectric switch, and safety door status of the rolling mill; The analog input channel collects the pressure signal of the rolling mill (pressure sensor output 4-20mA), the current signal of the motor (current transmitter output 4-20mA), and the rolling temperature signal; The digital output channel controls equipment such as the press down solenoid valve, roller drive motor, and fault alarm indicator light for the rolling mill. The high-speed response characteristic of the module ensures that the position signal of the steel plate is quickly captured and promptly fed back to the control system of the rolling mill, achieving precise control of the rolling mill action and improving the dimensional accuracy of the rolled products; Its strong anti-interference design can resist the electromagnetic radiation generated by large motors and frequency converters in the workshop, ensuring the reliability of signal acquisition and control.

4.3 Intelligent Manufacturing Assembly Production Line Control

The G3EFa module is a key component for achieving automated collaboration in intelligent manufacturing assembly production lines such as automotive parts and electronic components. The digital input channel collects signals from the position sensor of the robotic arm, the workpiece clamping detection switch, and the photoelectric sensor of the conveyor line; The analog input channel collects the operating speed signal and assembly pressure signal of the robotic arm; The digital output channel controls the action solenoid valve of the robotic arm, the start stop motor of the conveyor line, the action actuator of the assembly tool, and the status indicator light of the production line. The module realizes the action interlocking of each device through local logic (such as the mechanical arm can only start the assembly action after the workpiece is clamped), reducing dependence on the upper PLC and improving the response speed of the production line; When an exception occurs, quickly trigger an alarm and shutdown command to prevent the fault from escalating and reduce production line downtime.

4.4 Monitoring of photovoltaic power station combiner boxes in the energy industry

In distributed photovoltaic power plants, the G3EFa module is used for signal acquisition and auxiliary control of the combiner box: the digital input channel collects signals such as the fuse status and lightning protection device action status of each photovoltaic string in the combiner box; The analog input channel collects the current signals of each string (converted to 4-20mA by a current transmitter), the output voltage signal of the combiner box (0-10V), and the temperature signal inside the box; The cooling fan, fault alarm device, and emergency disconnect switch of the digital output channel control combiner box. The module will upload the collected data to the photovoltaic power station monitoring platform through PLC, and the operation and maintenance personnel can real-time grasp the operating status of the combiner box; When a certain string current is abnormal or the temperature inside the box is too high, the module locally triggers the start of the cooling fan or issues a fault alarm to ensure the stable power generation of the photovoltaic power station.

Installation and configuration points

5.1 Installation specifications

-The module is installed using DIN 35mm standard rails, and the installation location should be chosen in an area with good ventilation, away from high-temperature heat sources (such as heating equipment and motors), strong electromagnetic interference sources (such as frequency converters and transformers), and corrosive gases, avoiding direct sunlight and rainwater erosion;

-The installation distance between modules and other devices should not be less than 50mm to ensure good heat dissipation and prevent module temperature from being too high due to dense installation;

-Before wiring, the module power supply and on-site equipment power supply must be disconnected, and wiring must be strictly carried out according to the module terminal block identification: digital input/output channels distinguish positive and negative poles, analog input channels distinguish signal positive, negative, and shielded wires, power terminals distinguish positive and negative poles to avoid reverse connection or short circuit;

-Analog signal cables should use shielded twisted pair cables, with one end of the shielding layer grounded (grounding resistance ≤ 4 Ω) and laid separately from power cables (spacing ≥ 300mm) to reduce the impact of electromagnetic interference on analog signals;

-After the module installation is completed, it is necessary to check whether all wiring terminals are tightened, especially for analog signal wiring, to avoid measurement errors caused by poor contact; Push the module to ensure that it is securely installed on the guide rail without any looseness.

5.2 Configuration Process

1. Hardware connection: Connect the G3EFa module to the ABB AC500-S series PLC through the backplane bus, complete the module power wiring, digital input/output channel and field device wiring, and analog input channel and sensor/transmitter wiring. After the wiring is completed, carefully check and ensure that there are no errors before connecting the power supply;

2. Software configuration: Create a new project in ABB Control Builder Plus programming software, add G3EFa module (model selection “HENF450295R2”), and configure the bus address of the module (matching the PLC backplane bus address);

3. Channel parameter setting: According to the type of on-site equipment, configure the filtering time of the digital input channel, the signal type (current/voltage) and measurement range of the analog input channel, and set the fault threshold of each channel (such as the alarm threshold for analog signal exceeding the range);

4. Logic program writing: According to the production process requirements, write the local control logic of the module (such as signal interlocking, threshold comparison) and the data exchange program with the upper PLC to achieve automatic control and data uploading of on-site equipment;

5. Download and Test: Download the configuration parameters and control program to the PLC, start the system for testing, verify the accuracy of signal acquisition and normal output actions of each channel through module indicator lights and software monitoring screens, and simulate fault scenarios to test the effectiveness of the module’s protection and alarm functions.

Additional information

| Weight | 1.6 lbs |

|---|---|

| Dimensions | 35 × 24 × 13 in |

Reviews (0)

Be the first to review “ABB G3EFa HENF450295R2 Industrial Automation Module” Cancel reply

Shipping and Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.