“ABB 3BHB016295R0001 – Spare parts in stock” has been added to your cart. View cart

ABB SYN5302A-Z, V217 3BHB006716R0217 digital synchronizer

$28,458.00 Original price was: $28,458.00.$26,884.00Current price is: $26,884.00.个

ABB 5SHX1960L0006 3BHB016120R0002 3BHE019719R0101 GVC736BE101 High Voltage Inverter Module

$3,844.00 Original price was: $3,844.00.$3,274.00Current price is: $3,274.00.个

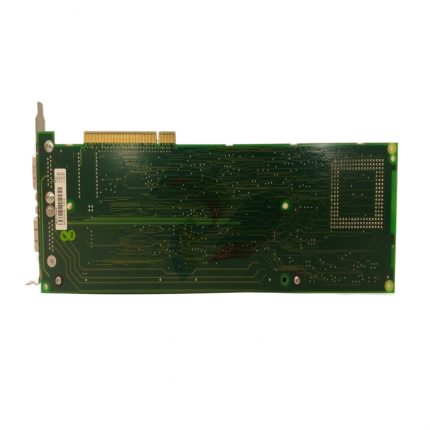

ABB NBIO-31 3BSE011337R1 I/O and Expansion Control Module

$7,375.00 Original price was: $7,375.00.$6,836.00Current price is: $6,836.00.个

The core of NBIO-31 module is positioned as a “bridge” connecting on-site sensors/actuators with the upper control system, mainly responsible for the input and output processing of digital signals and system I/O expansion tasks. It seamlessly connects with mainstream DCS (distributed control system) or PLC (programmable logic controller) such as ABB AC 800M through standardized communication interfaces, solving the centralized control and decentralized acquisition needs of multiple types of signals in industrial sites.

Category: ABB

Tag: NBIO-31 3BSE011337R1

Description

ABB NBIO-31 3BSE011337R1 I/O and Expansion Control Module

Module core positioning and application scenarios

The core of NBIO-31 module is positioned as a “bridge” connecting on-site sensors/actuators with the upper control system, mainly responsible for the input and output processing of digital signals and system I/O expansion tasks. It seamlessly connects with mainstream DCS (distributed control system) or PLC (programmable logic controller) such as ABB AC 800M through standardized communication interfaces, solving the centralized control and decentralized acquisition needs of multiple types of signals in industrial sites.

Typical application scenarios include:

-Discrete industrial control: start stop control of production line equipment, status monitoring (such as motor operation status, valve switch feedback), counting signal acquisition, etc;

-Process industry monitoring: parameter feedback of chemical reaction vessels, collection of switch status of power systems, equipment interlocking control in metallurgical processes;

-System expansion and upgrade: When the original control system’s I/O points are insufficient, low-cost and highly compatible I/O expansion can be achieved through the NBIO-31 module, without the need to replace the core controller.

Core functions and performance advantages

1. Rich I/O processing capability

The module focuses on precise processing of digital signals, supports multi-channel digital input (DI) and output (DO) functions, and can flexibly configure signal types (such as PNP/NPN input, relay/transistor output) according to on-site requirements. It integrates efficient signal filtering circuits internally, which can effectively suppress electromagnetic interference (EMI) in industrial sites, ensure the stability of signal transmission under complex working conditions (such as strong voltage and high dust environment), and the input signal response time can reach milliseconds, meeting real-time control requirements.

2. Flexible expansion and compatibility features

As an extended control module, NBIO-31 supports high-speed communication with the main controller through ABB’s dedicated backplane bus or industrial Ethernet (such as Profinet, EtherNet/IP), and can achieve “plug and play” expansion between modules. It can support up to multiple module cascades, greatly increasing the expansion limit of the system’s I/O points. At the same time, the module is compatible with mainstream programming software such as ABB Control Builder M. Engineers can complete module configuration, program writing, and debugging through a unified development environment, reducing the difficulty of system integration.

3. High reliability and industrial grade protection

The module adopts industrial grade components and compact structure design, with a wide temperature working range (usually supporting -20 ℃~60 ℃), which can adapt to harsh industrial site environments. It has built-in comprehensive fault diagnosis and protection functions, including overvoltage protection, overcurrent protection, module overheating protection, etc. When abnormal situations occur, it can provide real-time feedback of fault information to the upper system, making it easy for operation and maintenance personnel to quickly locate the problem. In addition, the module complies with industrial standards such as IEC 61131-2 and has good resistance to vibration and impact.

4. Convenient operation and management

The front of the module is equipped with clear LED status indicator lights, which can intuitively display the power status, communication status, and I/O signal status of each channel. Operation and maintenance personnel can quickly judge the operation status of the module without the need for professional equipment. At the same time, remote monitoring and parameter configuration of modules can be achieved through the upper control system, supporting online modification of I/O channel attributes, fault reset and other operations, reducing on-site operation and maintenance workload.

Key technical parameters

Basic Information

Order Number

3BSE011337R1

Power parameters

Working Voltage

Usually 24V DC (± 10% fluctuation range)

Power consumption

Typical value ≤ 5W (excluding load power consumption)

I/O channel

Digital Input (DI)

The number of channels is usually 16, supporting PNP/NPN input, with an input voltage range of 24V DC

Digital Output (DO)

The number of channels is usually 16, relay output (contact capacity: AC 250V/5A, DC 30V/5A)

response time

DI input ≤ 1ms, DO output ≤ 5ms

communication interface

bus type

Support ABB AC 800M backplane bus, Profinet, etc

communication rate

Supports up to 100Mbps (Ethernet), backplane bus speed compatible with the main controller

environmental parameters

Operating Temperature

-20℃~60℃

Protection level

Module body IP20 (installed inside the control cabinet)

Overall dimensions

Length x Width x Height

Typical value: 100mm × 80mm × 150mm (subject to actual product)

Key points of installation and integration

1. Installation specifications

The module needs to be installed in a control cabinet that meets industrial standards, avoiding direct sunlight, rainwater erosion, and corrosive gas corrosion. During installation, ensure that the module maintains sufficient heat dissipation space with other devices (recommended spacing ≥ 10mm), and is firmly fixed to prevent loose wiring caused by vibration. When wiring, it is necessary to strictly distinguish between power terminals and I/O signal terminals to avoid reverse polarity or short circuits.

2. System integration steps

1. Hardware connection: Connect the module to the main controller through a backplane bus or communication cable, connect it to a 24V DC power supply, and connect the I/O signal lines of the on-site sensors/actuators;

2. Software configuration: Add NBIO-31 module in Control Builder M (match model with order number), configure communication parameters and I/O channel attributes (such as input type and output mode);

3. Programming: According to control requirements, write I/O signal acquisition and control logic programs to achieve data exchange between modules and the main controller;

4. Debugging and operation: Monitor the status of the module through the upper computer, simulate on-site signal testing of I/O channel response, and troubleshoot communication faults and logic errors.

Common faults and troubleshooting methods

Fault phenomenon

Possible reasons

Troubleshooting method

The power indicator light is not on

Power not connected, power cord loose, power failure

Check if the power supply voltage is normal, unplug the power cord again, replace the power supply for testing

Communication indicator light flashing abnormally

Loose communication cables, mismatched communication parameters, and main controller malfunction

Check the communication cable connection, verify the communication parameters (IP address, bus address) between the module and the main controller, and restart the main controller

I/O channel unresponsive

Signal line connection error, channel failure, module configuration error

Check the wiring of the I/O signal line, replace the backup channel for testing, and recheck the I/O configuration parameters of the module

Module overheating alarm

Insufficient heat dissipation space, high ambient temperature, internal module malfunction

Clean up the debris around the module, check the cooling system of the control cabinet, and replace the faulty module

Additional information

| Weight | 3.7 lbs |

|---|---|

| Dimensions | 47 × 36 × 23 in |

Reviews (0)

Be the first to review “ABB NBIO-31 3BSE011337R1 I/O and Expansion Control Module” Cancel reply

Shipping and Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.