“ABB 3BSE007913R50 – Spare parts in stock” has been added to your cart. View cart

ABB HIEE401807R0001 Advanced Power Electronics Module

$5,809.00 Original price was: $5,809.00.$4,858.00Current price is: $4,858.00.个

GE SPU232.1-CAN PART NO: 029.354 630.

$7,373.00 Original price was: $7,373.00.$3,737.00Current price is: $3,737.00. 个

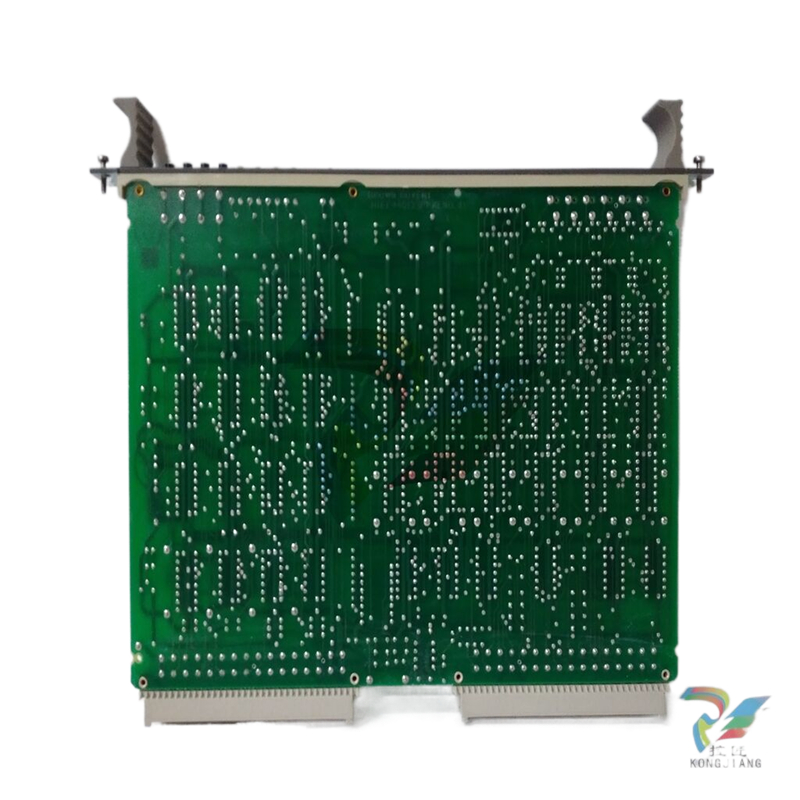

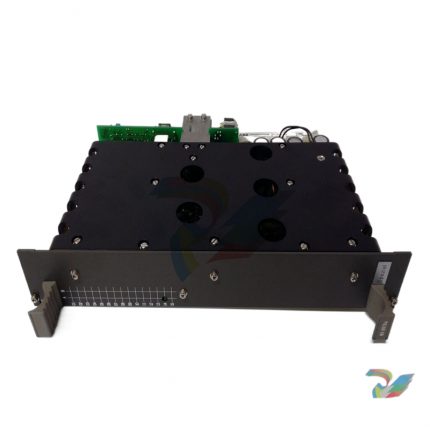

ABB VBS01-EPD Digital Signal Processing Module

$8,548.00 Original price was: $8,548.00.$8,045.00Current price is: $8,045.00.个

The ABB VBS01-EPD high-performance digital signal processing module is a core processing unit developed by ABB for complex industrial signal scenarios. Based on advanced digital signal processing (DSP) architecture and programmable logic gate array (FPGA) technology, it is designed to achieve precise acquisition, real-time operation, and intelligent analysis of high-frequency, weak, and multi interference signals in industrial fields. This module integrates high-speed signal conditioning, multi-channel parallel processing, and flexible algorithm configuration functions. It can perform millisecond level computational processing on complex signals such as vibration, noise, harmonics, and phase. Through seamless linkage with ABB’s dedicated industrial bus and control system, it provides core data support for equipment status monitoring, fault warning, and precise control. It is widely used in fields such as power equipment monitoring, precision manufacturing inspection, and heavy machinery diagnosis, and is a key hardware carrier for improving the intelligence level of industrial systems.

Description

ABB VBS01-EPD High Performance Digital Signal Processing Module

Product Overview

The ABB VBS01-EPD high-performance digital signal processing module is a core processing unit developed by ABB for complex industrial signal scenarios. Based on advanced digital signal processing (DSP) architecture and programmable logic gate array (FPGA) technology, it is designed to achieve precise acquisition, real-time operation, and intelligent analysis of high-frequency, weak, and multi interference signals in industrial fields. This module integrates high-speed signal conditioning, multi-channel parallel processing, and flexible algorithm configuration functions. It can perform millisecond level computational processing on complex signals such as vibration, noise, harmonics, and phase. Through seamless linkage with ABB’s dedicated industrial bus and control system, it provides core data support for equipment status monitoring, fault warning, and precise control. It is widely used in fields such as power equipment monitoring, precision manufacturing inspection, and heavy machinery diagnosis, and is a key hardware carrier for improving the intelligence level of industrial systems.

Additional Information

Product Type:Module_Termination_Unit

Ordering

HS Code:853710 — ELECTRICAL MACHINERY AND EQUIPMENT AND PARTS THEREOF; SOUND RECORDERS AND REPRODUCERS, TELEVISION IMAGE AND SOUND RECORDERS AND REPRODUCERS, AND PARTS AND ACCESSORIES OF SUCH ARTICLES; Boards, panels, consoles, desks, cabinets and other bases, equipped with two or more apparatus of heading|8535|or 8536, for electric control or the distribution of electricity, including those incorporating instruments or apparatus of Chapter|90, and numerical control apparatus, other than switching apparatus of heading|8517; For a voltage not exceeding 1|000|V

Customs Tariff Number:85371091

Dimensions

Product Net Depth / Length:270 mm

Product Net Height:130 mm

Product Net Width:140 mm

Product Net Weight:0 kg

Environmental

WEEE Category:5. Small Equipment (No External Dimension More Than 50 cm)

Number of Batteries:0

SCIP:45932460-9d5f-4246-9d0e-e1eb9e75d8c0 India

Core functional characteristics

1. Accurate acquisition of high-frequency weak signals

The module adopts a 24 bit high-precision AD converter and programmable gain amplifier (PGA), combined with a low-noise signal conditioning circuit, which can effectively collect weak signals with amplitudes as low as mV in industrial fields, such as equipment vibration acceleration signals, acoustic noise signals, etc. By using anti aliasing filtering technology (with configurable cutoff frequency) and adaptive noise suppression algorithm, the impact of environmental interference on signal acquisition is significantly reduced, and the signal-to-noise ratio can still be guaranteed to be ≥ 100dB in complex industrial environments, providing a reliable data foundation for subsequent accurate analysis.

2. High speed parallel signal processing capability

Based on the dual core architecture of “DSP+FPGA”, parallel operation of signal acquisition and data processing is achieved: FPGA is responsible for high-speed data caching, real-time signal preprocessing, and I/O logic control, while DSP focuses on complex algorithm operations, supporting 16384 point FFT real-time operation at a single channel sampling rate of 250kHz, with a frequency spectrum analysis response time of ≤ 1ms. It can simultaneously filter, peak detection, phase analysis, harmonic extraction and other processing of 8-channel signals to meet the needs of multi parameter synchronous monitoring, such as synchronous analysis of motor vibration and speed, grid voltage and harmonics.

3. Flexible algorithm configuration and expansion

Support algorithm customization configuration through ABB SignalPro programming software, with built-in standardized algorithm libraries for vibration analysis (effective value, peak factor, kurtosis), spectrum analysis (power spectrum, phase spectrum), harmonic analysis (THD, THD+N), etc. Users can combine algorithm processes according to scene requirements. The module reserves FPGA logic configuration interfaces, which can add specialized algorithms (such as equipment fault feature extraction and pattern recognition) through customized development to meet the personalized needs of special fields such as wind power and nuclear power.

4. High reliability and industrial environment adaptation

Adopting industrial grade reinforced design, achieving 1000Vrms high isolation between channels, effectively avoiding signal crosstalk and common mode interference; The core components undergo wide temperature screening from -40 ℃ to 85 ℃, and the module is equipped with temperature compensation and overheat protection circuits, which can work stably in extreme environments of -20 ℃ to 70 ℃. Through IEC 61000-6-2 anti-interference certification and IEC 60068-2 environmental reliability testing, it is suitable for industrial scenarios with high temperature, high humidity, and strong electromagnetic interference.

5. Seamless integration of high-speed communication and systems

Equipped with Gigabit Ethernet and Profinet IRT real-time industrial Ethernet interfaces, with a data transmission rate of up to 1Gbps, it supports seamless integration with ABB AC500 series PLCs, 800xA DCS systems, and third-party high-end controllers. Through PCIe 2.0 interface, it can be directly extended to ABB dedicated monitoring host, achieving local storage and fast calling of massive processed data. Support data partition transmission, prioritize real-time calculation results transmission, cache non real time data in the background to ensure timely response of the control system.

6. Intelligent diagnosis and status monitoring

The built-in device health status assessment model can automatically determine the operating status of the device based on processed signal data (such as vibration spectrum peak and harmonic distortion rate), and generate a health score (0-100 points). When the parameter exceeds the threshold, it immediately triggers a local alarm (digital output) and remote notification, while storing abnormal signal waveforms and spectrum data, providing complete data support for fault tracing and root cause analysis, and helping to achieve predictive maintenance.

7. Convenient debugging and operation management

Equipped with a 7-inch color touch screen, supporting Chinese/English interface switching, it can display multi-channel signal waveforms, spectrograms, calculation results, and device status in real time, and complete parameter configuration and algorithm startup through touch operation. Support USB 3.0 interface to quickly export historical data and calculation reports. ABB SignalPro software provides offline data analysis and algorithm simulation functions, which is convenient for operation and maintenance personnel to debug algorithm parameters in advance and shorten on-site deployment time.

Applicable scenarios

-Monitoring of power equipment: Collecting and analyzing vibration and noise signals of generators and transformers, identifying hidden dangers such as loose iron cores and winding faults through spectral features

-Precision manufacturing inspection: monitoring of spindle vibration and identification of tool wear status, real-time warning of machining accuracy deviation through vibration spectrum changes

-Wind power equipment diagnosis: analysis of vibration signals of wind turbine gearbox and bearings, combined with speed signals to achieve early warning of faults and life assessment

-Power grid quality monitoring: collection of voltage harmonics and flicker signals at the grid connection of new energy power stations, analysis of power quality, and generation of compliance reports

-Maintenance of heavy machinery: Monitoring vibration and impact signals of mining crushers and rolling mills to determine the wear and structural looseness status of equipment components

-Aerospace testing: synchronous acquisition and joint analysis of vibration, temperature, and pressure parameters during ground testing of aircraft engines to verify equipment performance

Precautions for use

1. Before installation, it is necessary to confirm that the module model matches the monitoring signal type and frequency range. Signal input, power supply, and communication terminals should be strictly distinguished according to the product manual. Weak signal channels should be wired with shielded twisted pair cables to avoid parallel installation with strong current circuits.

2. The installation location should be far away from strong electromagnetic radiation sources such as frequency converters and high-power motors. The grounding resistance of the module should be ≤ 4 Ω to ensure good grounding and suppress common mode interference. A forced cooling fan should be equipped in high temperature environments.

3. Before the first operation, channel calibration (zero point, gain, phase) needs to be completed through SignalPro software. The sampling rate, filtering parameters, and algorithm flow should be configured according to the monitoring object. It is recommended to verify the accuracy of acquisition and operation through a standard signal source.

4. During operation, it is necessary to regularly check the tightness of signal cable connections to avoid loose joints caused by vibration. The module should be self diagnosed quarterly through software to confirm that the AD converter, communication interface, and algorithm are operating normally.

When the module sends out an alarm signal, the monitoring equipment should be checked for abnormalities first. The signal data and spectrum of the abnormal period should be retrieved through software, and the cause of the fault should be analyzed in combination with the operating conditions of the equipment to avoid misjudgment.

When performing software upgrades or algorithm updates, it is necessary to first backup the current parameter configuration and historical data. During the upgrade process, ensure stable power supply and prohibit power interruption. After the upgrade is completed, a no-load test should be conducted to verify that the function is normal.

7. Module maintenance must be carried out by professionals with industrial signal processing equipment debugging qualifications. Before maintenance, the power supply must be cut off and discharged. Non professionals are prohibited from disassembling or modifying the internal FPGA logic configuration without authorization.

Additional information

| Weight | 6.12 lbs |

|---|---|

| Dimensions | 54 × 54 × 12 in |

Reviews (0)

Be the first to review “ABB VBS01-EPD Digital Signal Processing Module” Cancel reply

Shipping and Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.