“GE DS200TBQDG1A – RST Terminal Board” has been added to your cart. View cart

GE GALIL DMC9940 Advanced Motion Controller

$4,854.00 Original price was: $4,854.00.$4,375.00Current price is: $4,375.00.个

GE IS200AEADH4A 109W3660P001 Input Terminal Board

$25,684.00 Original price was: $25,684.00.$22,745.00Current price is: $22,745.00.个

GE DMC-9940 Industrial Motion Control Card

$8,454.00 Original price was: $8,454.00.$8,054.00Current price is: $8,054.00.个

GE DMC-9940 is a high-performance motion control card launched by General Electric (GE) for high-precision industrial motion control scenarios, and is a core component of GE’s industrial automation control product system. This product is designed specifically for multi axis collaborative control requirements, and can achieve precise position control, speed control, and torque control of actuators such as servo motors and stepper motors. It is a key bridge connecting the upper control system and the lower level actuators. It adopts advanced control chips and optimized control algorithms, with characteristics such as fast response speed, high control accuracy, and strong stability. It can be widely adapted to industrial fields with strict requirements for motion control accuracy, such as machine tool processing, automated production lines, robots, printing and packaging.

Description

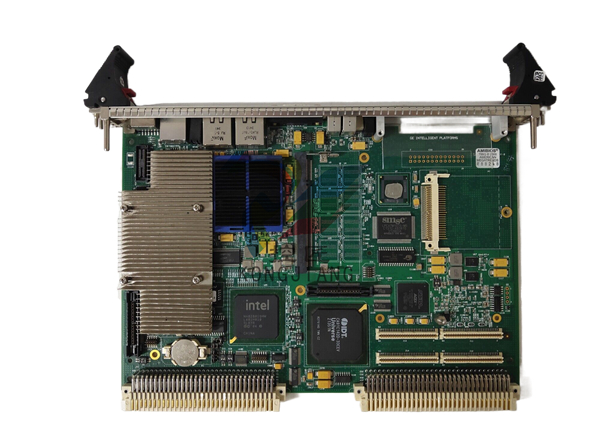

GE DMC-9940 Industrial Motion Control Card

Product Overview

GE DMC-9940 is a high-performance motion control card launched by General Electric (GE) for high-precision industrial motion control scenarios, and is a core component of GE’s industrial automation control product system. This product is designed specifically for multi axis collaborative control requirements, and can achieve precise position control, speed control, and torque control of actuators such as servo motors and stepper motors. It is a key bridge connecting the upper control system and the lower level actuators. It adopts advanced control chips and optimized control algorithms, with characteristics such as fast response speed, high control accuracy, and strong stability. It can be widely adapted to industrial fields with strict requirements for motion control accuracy, such as machine tool processing, automated production lines, robots, printing and packaging.

Core functions and advantages

1. Multi axis high-precision collaborative control

The DMC-9940 motion control card supports multi axis synchronous control function, and can achieve up to 16 axis (specific configuration subject to actual) collaborative operation, which can meet the multi axis linkage requirements in complex motion scenes. It is equipped with a high-precision pulse generation module, with a pulse output frequency of up to 2MHz and a positioning accuracy of micrometer level. It also supports various advanced motion control modes such as electronic cam, electronic gear, linear interpolation, and circular interpolation. Whether it is the complex surface machining of machine tools or the precise trajectory movement of robots, this control card can ensure the synchronization and consistency of each axis movement through precise pulse control or bus control, greatly improving the machining accuracy and production efficiency of the equipment.

2. Rich control interfaces and compatibility

To meet the connection requirements of devices in different industrial scenarios, DMC-9940 is equipped with rich hardware interfaces. In terms of control signal output, it supports multiple pulse output modes such as pulse+direction and differential pulse, and can be directly connected to mainstream brands of servo drivers and stepper drivers; In terms of feedback signal input, it has incremental encoder interface and absolute encoder interface, which can collect real-time motor operation status data, achieve closed-loop control, and further improve control accuracy. At the same time, the control card supports PCI/PCIe bus interface, which can be quickly integrated into industrial control computers. It is compatible with mainstream operating systems such as Windows and Linux, as well as development platforms such as LabVIEW and VC++, reducing the difficulty of system development and integration.

3. Efficient real-time control and response capability

The product adopts a high-performance 32-bit embedded processor, combined with GE’s self-developed real-time motion control core, which can achieve fast parsing and execution of control instructions, with a control cycle as short as 1ms, ensuring real-time monitoring and adjustment of motor operation status. When abnormal situations such as position deviation and speed fluctuation occur during the operation of the device, the control card can complete signal acquisition, deviation calculation, and correction instruction output in a very short time, effectively suppressing the influence of interference factors on motion control accuracy and ensuring the stability of device operation. In addition, it has hardware level position comparison and capture functions, which can achieve precise triggering of specific positions and meet the requirements of precise positioning and action switching in automated production.

4. Comprehensive fault diagnosis and protection mechanism

To enhance the safety and reliability of equipment operation, DMC-9940 is equipped with comprehensive fault diagnosis and protection functions. By monitoring key parameters such as current, voltage, temperature, and position deviation of the motor in real-time, fault states such as overcurrent, overvoltage, overload, and overtravel can be identified in a timely manner, and corresponding protective actions can be triggered immediately, such as stopping the motor operation, cutting off control signals, etc., to avoid damage to the control card and actuator caused by the expansion of faults. At the same time, the control card has a fault information storage function, which can record the time, type, and related parameters of the fault occurrence, providing accurate data support for on-site engineers’ fault diagnosis and equipment maintenance, and shortening equipment downtime.

5. Convenient development and debugging tools

GE has provided dedicated motion control development software and debugging tools for the DMC-9940 motion control card, offering a graphical programming interface and a rich API function library. Engineers can quickly develop control programs by dragging and dropping modules and configuring parameters without the need for a deep understanding of complex motion control algorithms; The debugging tool supports real-time monitoring of the operating parameters (position, speed, torque, etc.), pulse output status, and fault information of each axis. It has functions such as online parameter modification and motion trajectory simulation, greatly simplifying the system debugging process and reducing development and maintenance costs.

Key technical parameters

Product Model

GE DMC-9940

number of controlled axes

Maximum 16 axes (configurable)

control mode

Position control, speed control, torque control

Pulse output mode

Pulse+direction, differential pulse

Maximum pulse output frequency

2MHz

feedback interface

Incremental encoder (A/B phase), absolute encoder (SSI/Profinet)

Control cycle

1ms~10ms (configurable)

Bus interface

PCIe 2.0 / PCI

Digital input/output

32 optocoupler isolated digital input, 16 relay output

working power supply

DC 5V ±5%,DC 24V ±10%

Operating Temperature

0℃ ~ 60℃

relative humidity

10%~90% (no condensation)

Applicable operating system

Windows XP/7/10/11, Linux Ubuntu 16.04 and above

Applicable scenarios and application cases

1. Applicable scenarios

-Machine tool processing industry: used for multi axis linkage control of CNC lathes, milling machines, machining centers and other equipment, realizing high-precision cutting, drilling and other machining operations of complex parts, improving machining accuracy and surface quality.

-Automated production line: adapted to assembly production lines, sorting production lines, etc., to achieve precise position control and speed adjustment of conveying mechanisms and robotic arms, ensuring the coordinated and efficient operation of various processes and improving production pace.

-Robotics field: used for joint motion control of industrial robots and collaborative robots, achieving precise trajectory planning and action execution of robots through multi axis synchronous control, meeting the needs of welding, handling, assembly and other operations.

-Printing and packaging industry: applied to printing machines, die-cutting machines, labeling machines and other equipment, controlling the movement speed and position of the paper feeding mechanism and cutting mechanism, ensuring the alignment of printing patterns, accurate cutting size, and improving product qualification rate.

-Electronic manufacturing industry: used for semiconductor packaging equipment, SMT surface mount machines, etc., to achieve precise picking, positioning, and placement of chips and components, meeting the high-precision requirements of electronic manufacturing.

2. Typical application cases

In the upgrade and renovation project of a CNC milling machine, a precision machining factory replaced the old control module with GE DMC-9940 motion control card to achieve coordinated control of the X, Y, Z axes and spindle of the milling machine. The control card receives processing instructions from the upper computer, accurately outputs pulse signals to control the operation of each axis servo motor, and collects real-time motor position feedback signals through the encoder interface to form closed-loop control. After the transformation, the positioning accuracy of the milling machine has been improved from 0.02mm to 0.005mm, the machining error of complex curved parts has been reduced by 60%, the machining efficiency has been improved by 30%, and the failure rate during equipment operation has significantly decreased, effectively reducing production and maintenance costs.

Installation and usage precautions

1. Before installation, it is necessary to confirm that the control card model matches the interface of the upper computer motherboard (PCI/PCIe), check that the gold fingers of the control card are not oxidized, and that the pins are not deformed to avoid affecting use due to hardware incompatibility or transportation damage.

2. The installation of the control card should be carried out in a power-off state. When inserting it into the PCI/PCIe slot, it is necessary to ensure that it is installed in place and firmly fixed to avoid poor contact that may cause abnormal signal transmission or equipment damage.

During the wiring process, it is necessary to strictly distinguish between the control signal interface and the power interface, and accurately connect external devices such as servo drives, encoders, limit switches, etc. according to the wiring manual to avoid faults caused by reverse polarity or signal misconnection.

4. The working environment of the control card should be kept clean and ventilated, avoiding dust accumulation, direct sunlight, and humid environments. The working temperature should be controlled within the range of 0 ℃~60 ℃ and kept away from strong electromagnetic interference sources (such as high-power transformers and frequency converters).

5. Before system debugging, it is necessary to install the supporting driver program and development software to ensure that the software version matches the control card model; During the debugging process, a single axis motion test should be conducted first to confirm that each axis is running normally before conducting a multi axis linkage test to gradually optimize control parameters.

6. In daily use, it is necessary to regularly maintain the control card, including cleaning the surface dust of the card body, checking the connection status of the wiring terminals, and regularly backing up the control program and parameters to avoid data loss due to unexpected situations.

When the control card malfunctions, the external wiring and equipment status should be checked by cutting off the power first. If the problem cannot be solved, professional technicians should be contacted for maintenance. It is forbidden to disassemble the internal components of the control card by oneself.

Additional information

| Weight | 3.24 lbs |

|---|---|

| Dimensions | 4573 × 4363 × 2536 in |

Reviews (0)

Be the first to review “GE DMC-9940 Industrial Motion Control Card” Cancel reply

Shipping and Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.